Oil injection nozzle for multifunctional lubricating oil gun

A kind of lubricating oil, multi-functional technology, applied in the direction of lubricating parts, engine lubrication, engine components, etc., can solve the problems of inability to refuel, unchanged refueling, wear and tear of parts, etc., to achieve the effect of convenient refueling and prevent the loss of caps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

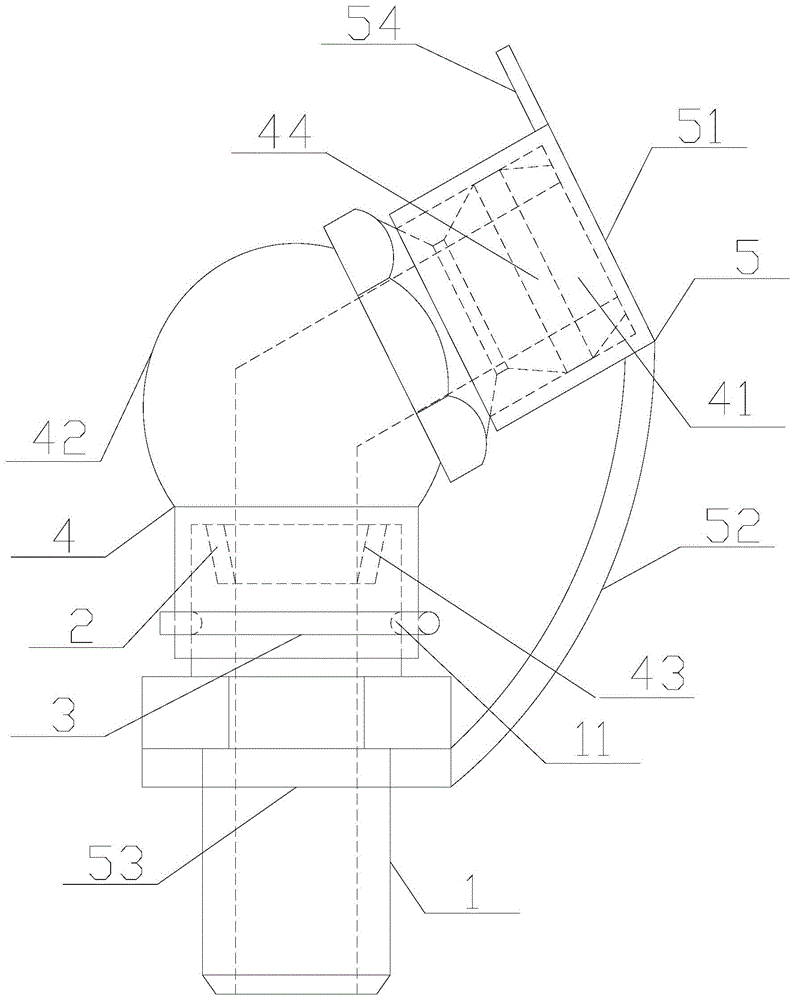

[0015] refer to figure 1 , a grease nozzle for a multifunctional lubricating gun according to the present invention, comprising a connection flange 1, a sealing ring 2, a retaining spring 3, a connection grease head 4 and a dust cover 5, and the connection flange 1 is provided with a connection grease head 4. The connecting oil filling head 4 is set on the connecting flange 1 and is rotatably connected together by the circlip 3. A sealing ring 2 is provided between the first insertion pipe 43 of the connecting oil filling head 4 and the connecting flange 1 , the inner passage of the connecting oil filling head 4 communicates with the inner passage of the connecting flange 1, the connecting oil filling head 4 is provided with a second insertion pipe 41, and the second insertion pipe 41 is inclined upward in a gradient, the anti The dust cover 5 includes a cap 51, a connecting band 52 and a collar 53, the cap 51 is connected with the collar 53 through the connecting band 52, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com