Motor-pump-integrated micro high-speed magnetic pump

A magnetic pump and integrated technology, which is applied in the direction of pumps, pump devices, mechanical equipment, etc., can solve the problems of difficulty in meeting the technical upgrading requirements of aerospace and aviation fields, large volume and weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

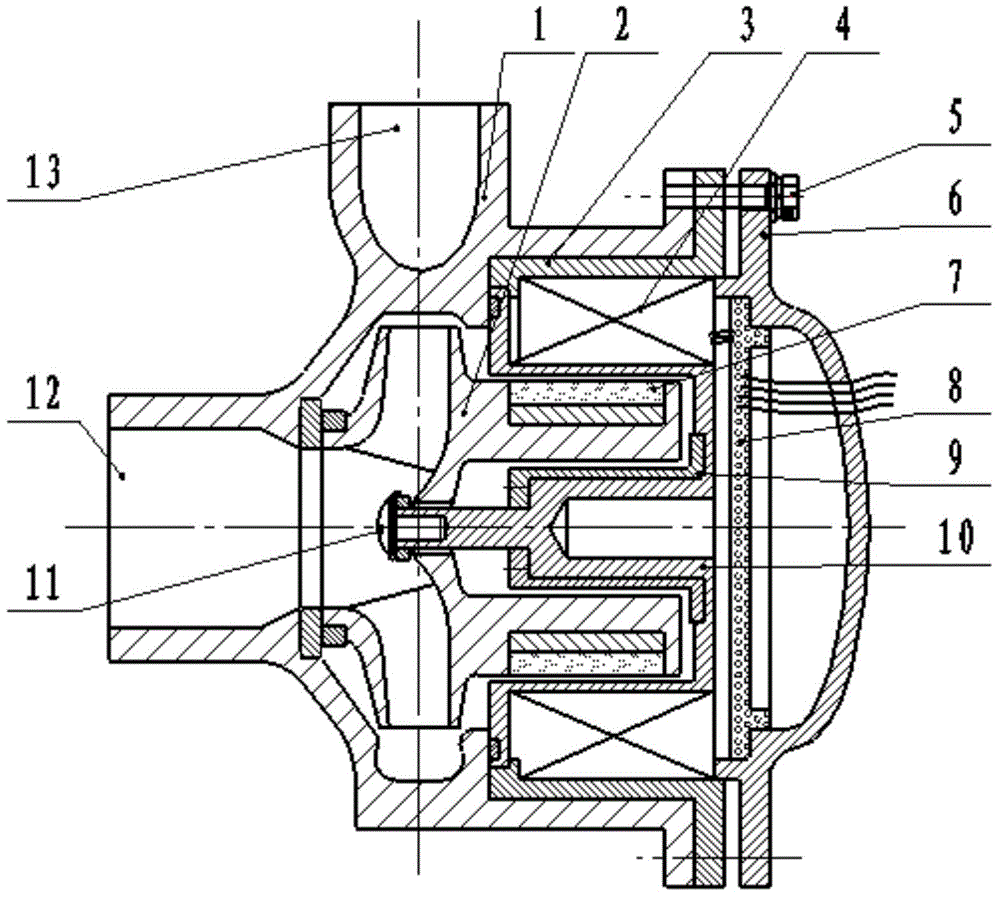

[0016] like figure 1 As shown, the motor-pump integrated miniature high-speed magnetic pump of the present invention includes a pump casing 1, an impeller 2, a motor casing 3, a stator winding 4, a spacer 10, a motor cover plate 6, a drive circuit board 8, a magnetic rotor, permanent magnet 7. The outer peripheral surface of the rear cover of the impeller 2 has an annular groove, and the permanent magnet 7 is fixed in the annular groove. The impeller 2 and the permanent magnet 7 embedded on the back cover of the impeller 2 form a magnetic rotor. The axis position of the rear cover of the impeller 2 has a groove; the spacer 10 is in the shape of a "bow" and has a protrusion that can be embedded into the rear cover of the impeller 2, and the protrusion is embedded behind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com