Steel thermal insulation fireproof door

A fire door, steel technology, applied in the field of fire doors, can solve the problems of poor improvement effect, rising material cost, poor fire protection effect, etc., to achieve good fire sealing effect, reduce waste and defective products, and good resistance to deformation. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

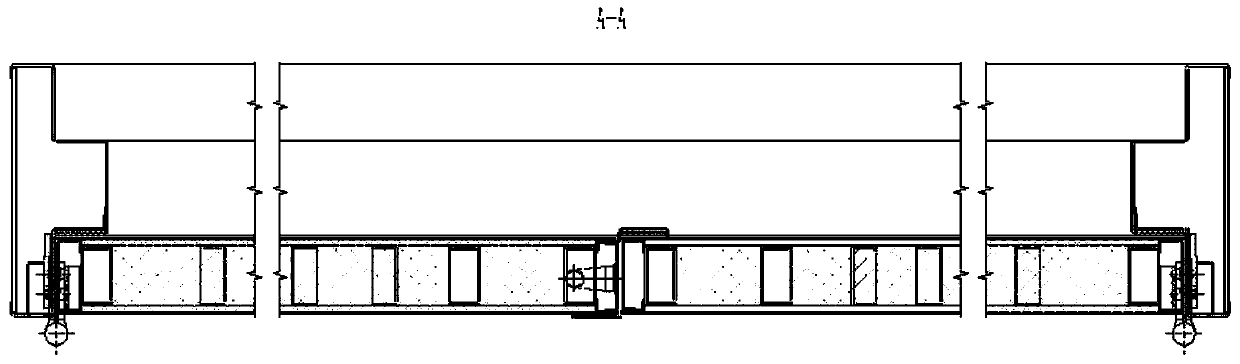

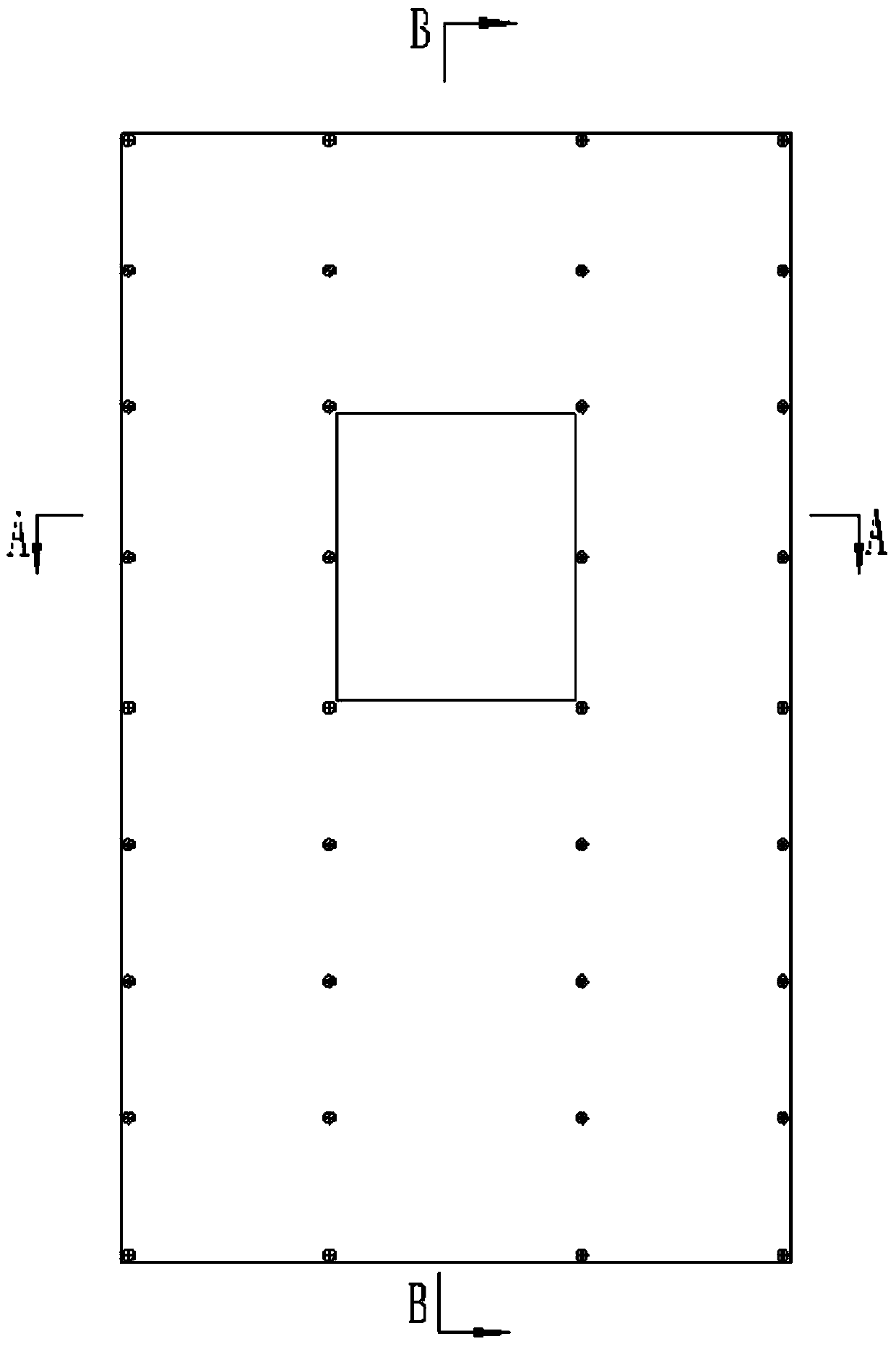

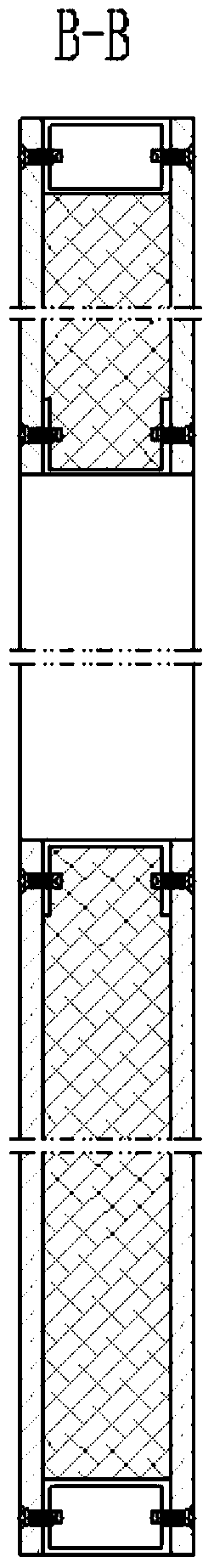

[0033] see Figure 1-2 , The door frame 1 is made in a stepped section shape, and cement filler is poured into the frame. The door frame 1 is equipped with a door leaf 7 composed of a keel and a panel. The door leaf 7 is composed of two layers of galvanized steel plates plus two layers of fireproof board 10, a skeleton and a fireproof board 11. The fireproof board 10 is connected to the keel by countersunk head screws 9. A longitudinal side of the door leaf 7 is connected with the door frame 1 by a hinge 8, and the door leaf 7 is connected with the fire-resistant glass by beading and welding. The top of the door leaf 7 and the upper part of the door frame 1 are equipped with a door closer and a positioner, and the longitudinal direction of the door leaf 7 is free. The side is equipped with a fireproof lock, and a deadbolt hole is set with the door frame 1, and fire strips are installed around the door frame to increase the fireproof performance.

[0034] see Figure 3-6 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com