Self-compacting concrete jack-up pouring construction method for steel tube arch bridges

A technology of self-compacting concrete and construction method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., and can solve the problem that the middle and top of steel pipes are difficult to meet compactness requirements, structural mechanical performance requirements, and safety requirements cannot be met, etc. problems, to achieve the effect of reducing continuous operation time, conforming to initial setting time, and small slump loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

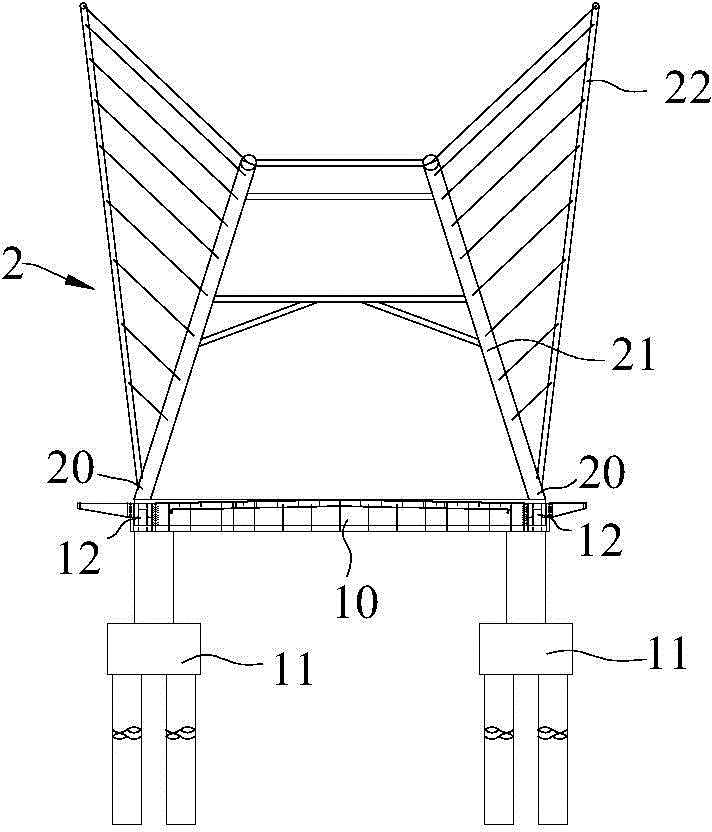

[0045] refer to Figure 3 to Figure 11 , the present invention provides a method for jacking and pouring self-compacting concrete of a steel pipe arch bridge, comprising the following steps:

[0046]S10 respectively set up pouring holes 14 at the four arch feet 20 of the main arch 21 and the bottom of the oval tube 12, and connect the grouting pipes and check valves at each pouring hole 14, and set them at the sag / 2 position of the main arch 21 Spare pouring holes 15, and spare grouting pipes and check valves are connected at the spare pouring holes 15, sub-chambers 23 are set in the vault of the main arch 21, and the sub-chambers 23 divide each main arch 21 into two A sub-arch, the top of each sub-arch is set with overflow holes 24 at the positions of 500mm on both sides of the vault sub-cupboard 23, and connect the overflow pipes at the overflow holes 24; At the highest position of the divided steel pipe warehouse, a number of small round holes with a diameter of 30mm are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com