A Composite Motor with High Precision Positioning

A compound, high-precision technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electromechanical device, etc., can solve the problem that the traveling wave ultrasonic motor cannot run continuously for a long time, Achieve the effect of shortening continuous working time, strong adaptability, and broadening application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

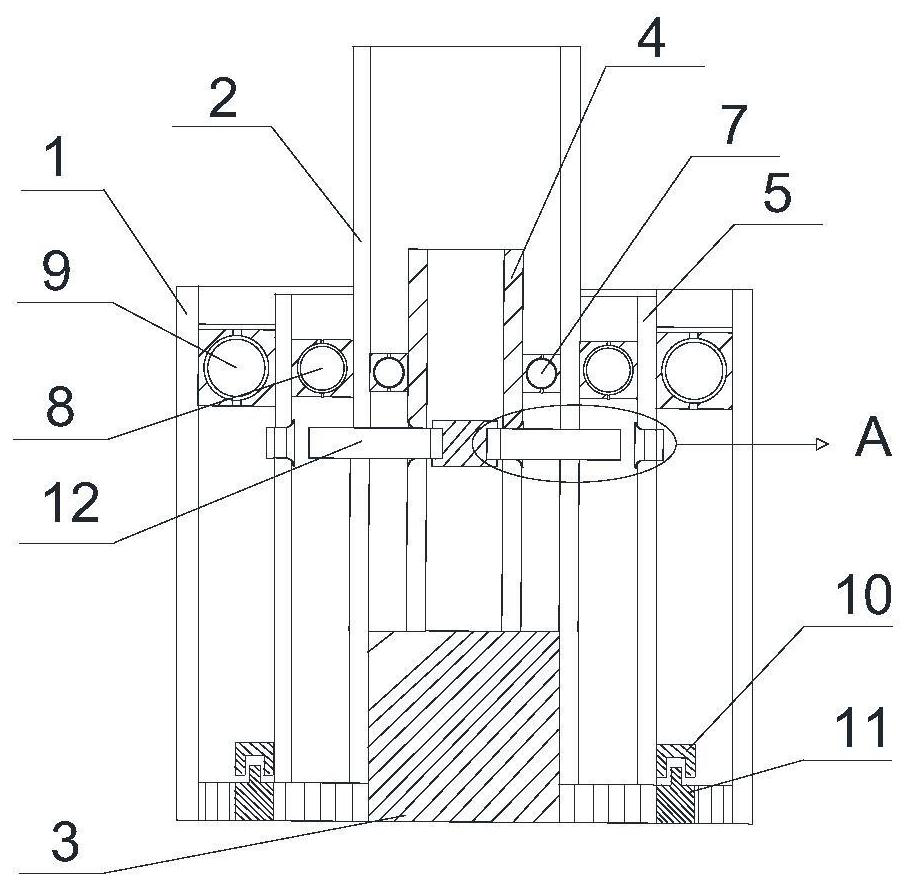

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0021] In order to solve the problem in the prior art that the annular traveling wave ultrasonic motor cannot work for a long time in the process of large stroke precision positioning, the present invention provides a compound motor with high precision positioning.

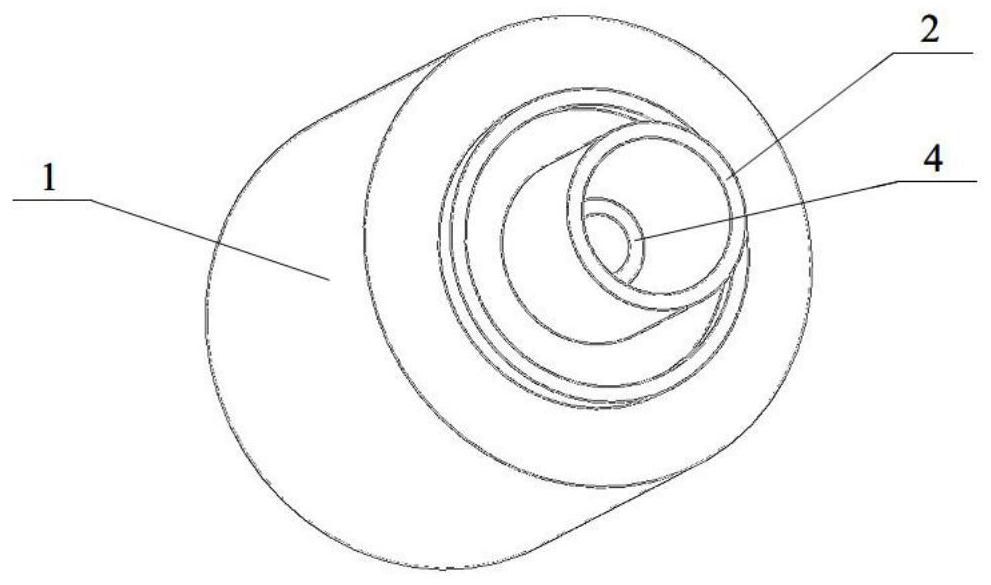

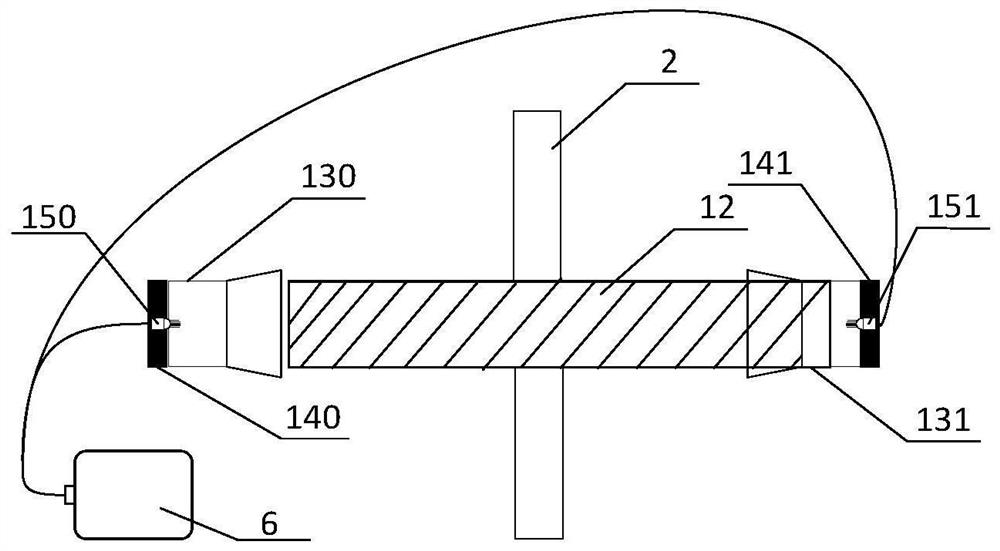

[0022] Such as Figure 1 to Figure 3 As shown, the composite motor includes: a housing 1, a rough positioning assembly, a hollow output shaft 2, a fine positioning assembly, a power switching device and a controller 6; the rough positioning assembly includes a stepping motor 3 and a first hollow shaft 4, and the stepping The motor 3 is fixedly arranged on the bottom of the housing 1, the first hollow rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com