A kind of preparation method of SERS substrate monolayer film and this SERS substrate monolayer film

A single-layer film and substrate technology, applied in coatings, metal material coating technology, nanotechnology for materials and surface science, etc., can solve the problem of inability to obtain uniform metal nanoparticles on the enhanced substrate, small SERS substrate, Problems such as excellent sensitivity have not been achieved, and the effects of Raman peak strength, high sensitivity, and good recognition have been achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

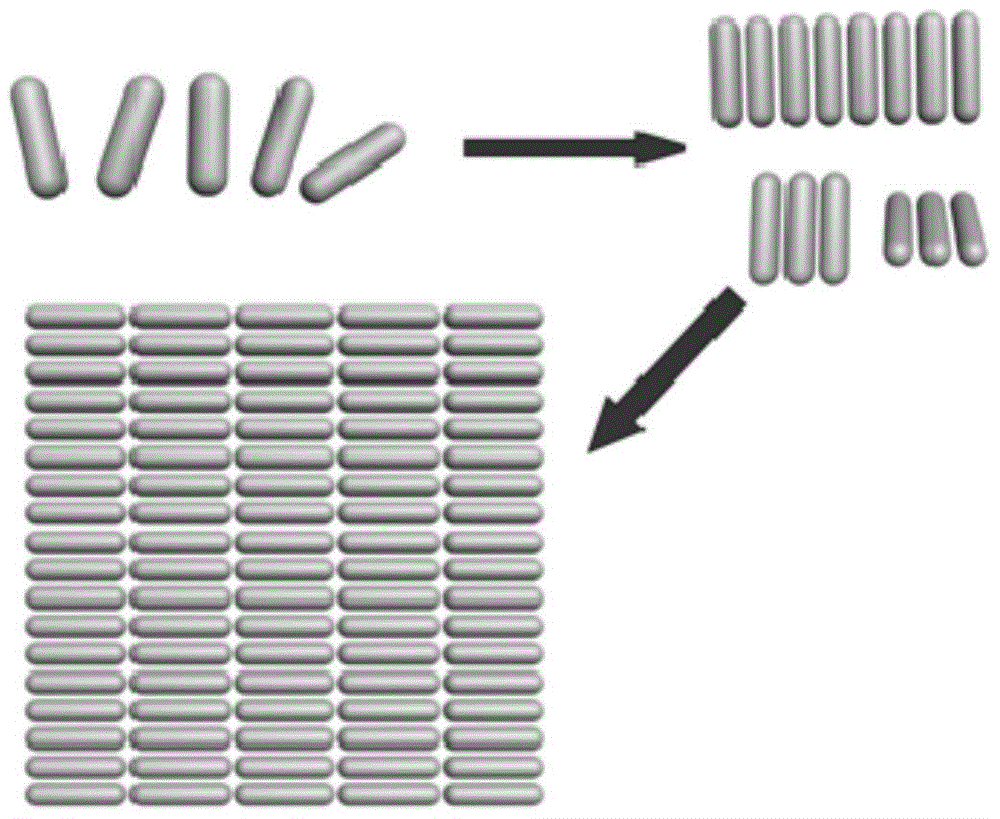

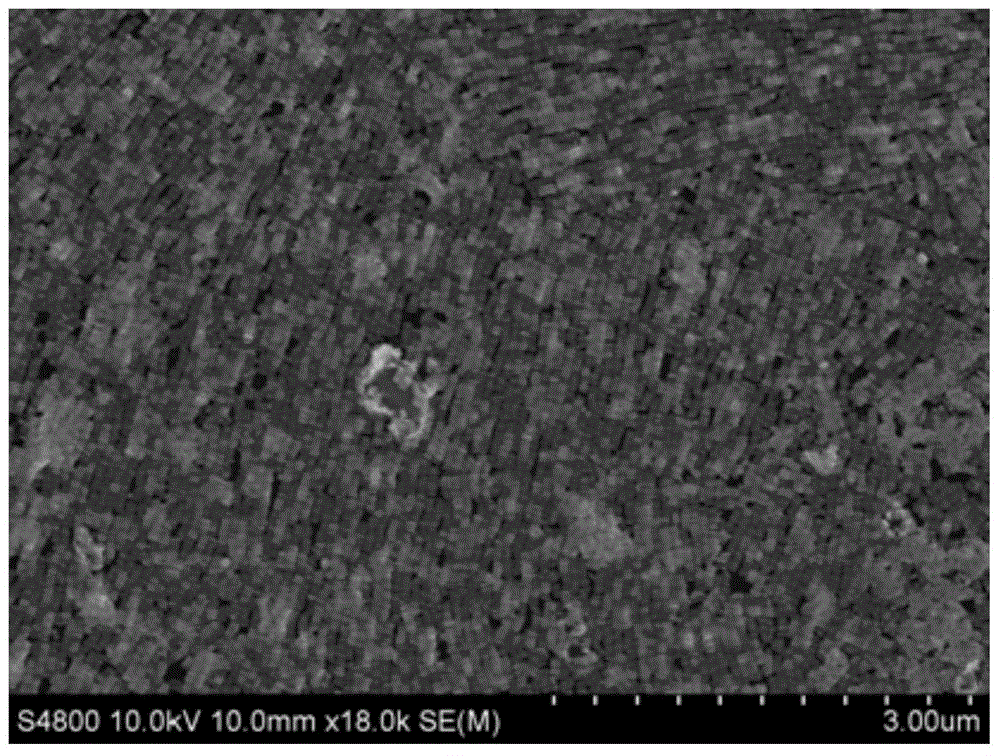

[0032] Example 1: Preparation method of gold nanorod tiled self-assembled SERS substrate monolayer film

[0033] The aqueous solution of gold nanorods with an aspect ratio of 3.8 was prepared by seed growth method. The prepared gold nanorod aqueous solution was centrifuged and concentrated, and then dispersed at a concentration of about 1×10 -6 moL -1In the CTAB aqueous solution, the concentration ratio of gold nanorods and CTAB in the obtained gold nanorod CTAB aqueous solution is 1:1000, and it is left to stand for subsequent use. Prepare the ligand replacement solution, that is, the ethanol solution of mercaptoalkane, wherein the volume ratio of mercaptoalkane to ethanol is about 1:9. Take the gold nanorod CTAB aqueous solution in the sample bottle, drop the mercaptoalkane solution and stir at a constant speed at 600r / min for 1 minute, make it fully contact with the gold nanorod for effective ligand replacement, the mercaptoalkane ethanol solution and The volume ratio of...

Embodiment 2

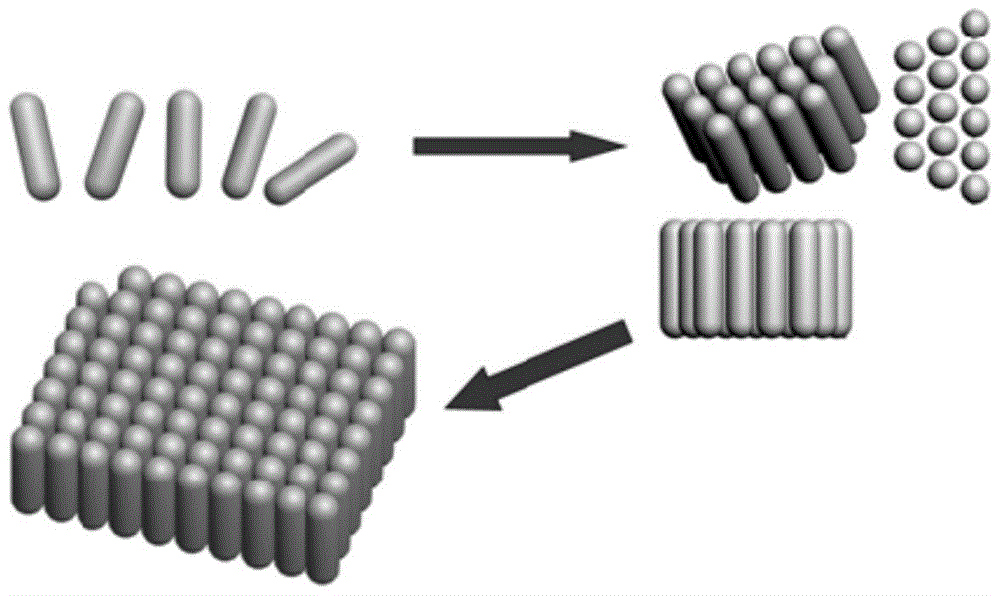

[0035] An aqueous solution of gold nanorods with an aspect ratio of 4.2 was prepared using the seed growth method. The prepared gold nanorod aqueous solution was centrifuged and concentrated, and then dispersed at a concentration of about 15×10 -6 moL -1 In the CTAB aqueous solution, the concentration ratio of gold nanorods and CTAB in the obtained gold nanorod CTAB aqueous solution is 3:1000, and it is left to stand for subsequent use. Prepare the ligand replacement solution, that is, the ethanol solution of mercaptoalkane, wherein the volume ratio of mercaptoalkane to ethanol is about 1:4. Take the gold nanorod CTAB aqueous solution in the sample bottle, drop the mercaptoalkane solution and stir at a constant speed at 800r / min for 6 minutes, make it fully contact with the gold nanorod to carry out effective ligand replacement, the mercaptoalkane ethanol solution and The volume ratio of the gold nanorod CTAB aqueous solution was 1:10 to obtain a ligand replacement mixed sol...

Embodiment 3

[0037] Aqueous solutions of gold nanorods with an aspect ratio of 4.0 were prepared using the seed growth method. The prepared gold nanorod aqueous solution was centrifuged and concentrated, and then dispersed at a concentration of about 8×10 -6 moL -1 In the CTAB aqueous solution, the concentration ratio of gold nanorods and CTAB in the obtained gold nanorod CTAB aqueous solution is 2:1000, and it is left to stand for subsequent use. Prepare the ligand replacement solution, that is, the ethanol solution of mercaptoalkane, wherein the volume ratio of mercaptoalkane to ethanol is about 2:7. Take the gold nanorod CTAB aqueous solution in the sample bottle, add dropwise the mercaptoalkane solution and stir at a constant speed at 700r / min for 4 minutes, make it fully contact with the gold nanorod to carry out effective ligand replacement, the mercaptoalkane ethanol solution and The volume ratio of the gold nanorod CTAB aqueous solution is 1:9 to obtain a ligand replacement mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com