A kind of ionic liquid functionalized temperature-responsive composite membrane and its preparation method

A temperature-responsive, ionic liquid technology, applied in the field of ionic liquid-functionalized temperature-responsive composite membranes and its preparation, can solve the problems of harsh surface-induced living radical polymerization modification methods, single response temperature, complex and cumbersome processes, etc. , to achieve a good industrial production basis, obvious control effects, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In an aqueous solution containing 4.50 mg / mL vinylimidazole, 10.5 mg / mL N-isopropylacrylamide, 0.625 mg / mL azobisisobutylamidine hydrochloride, and 5.21 mg / mL bromoethane, put Brominated polyphenylene ether-based film, then placed at 70 o C temperature, constant temperature reaction for 5 hours, and then the membrane was taken out to obtain an ionic liquid functionalized temperature-responsive composite membrane.

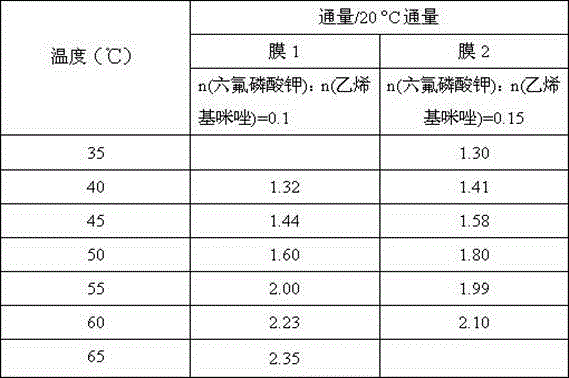

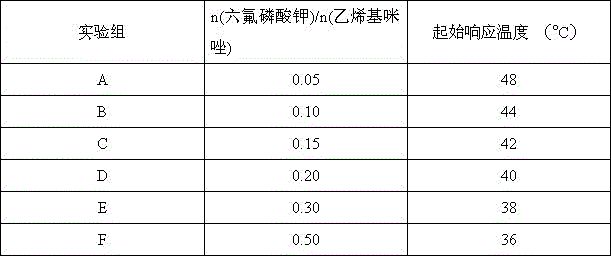

[0021] Then, the ionic liquid functionalized temperature-responsive composite membrane was re-mixed with the reaction solution containing different concentrations of potassium hexafluorophosphate, the reaction solution of group A contained 0.022 mg / mL potassium hexafluorophosphate, and the reaction solution of group B contained 0.044 mg / mL potassium hexafluorophosphate. mL potassium hexafluorophosphate, group C reaction solution contains 0.066 mg / mL potassium hexafluorophosphate, group D reaction solution contains 0.13 mg / mL potassium hexafluorophosphate, gro...

Embodiment 2

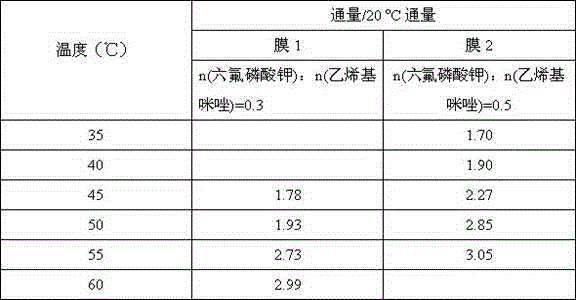

[0029] In an aqueous solution containing 7.50 mg / mL vinylimidazole, 17.5 mg / mL N-isopropylacrylamide, 1.04 mg / mL azobisisobutylamidine hydrochloride, and 8.68 mg / mL bromoethane, put Brominated polyphenylene ether-based film, then placed at 70 o C temperature, constant temperature reaction for 5 hours, and then take out the membrane to obtain an ionic liquid functionalized temperature-responsive composite membrane;

[0030] Then, the ionic liquid functionalized temperature-responsive composite membrane was re-mixed with the reaction solution containing different concentrations of potassium hexafluorophosphate, the reaction solution of group A contained 0.037 mg / mL potassium hexafluorophosphate, and the reaction solution of group B contained 0.073 mg / mL potassium hexafluorophosphate. mL potassium hexafluorophosphate, group C reaction solution contains 0.11 mg / mL potassium hexafluorophosphate, group D reaction solution contains 0.15 mg / mL potassium hexafluorophosphate, group E re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com