Magnesium sodium phosphate cement base material and preparation method thereof

A cement-based material, a technology of sodium magnesium phosphate, applied in the field of cement, can solve the problems of slow solidification rate of Portland cement, difficult to achieve pumping and injection, unstable raw material quality, etc., to achieve excellent performance such as adhesion, cost Low, good quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

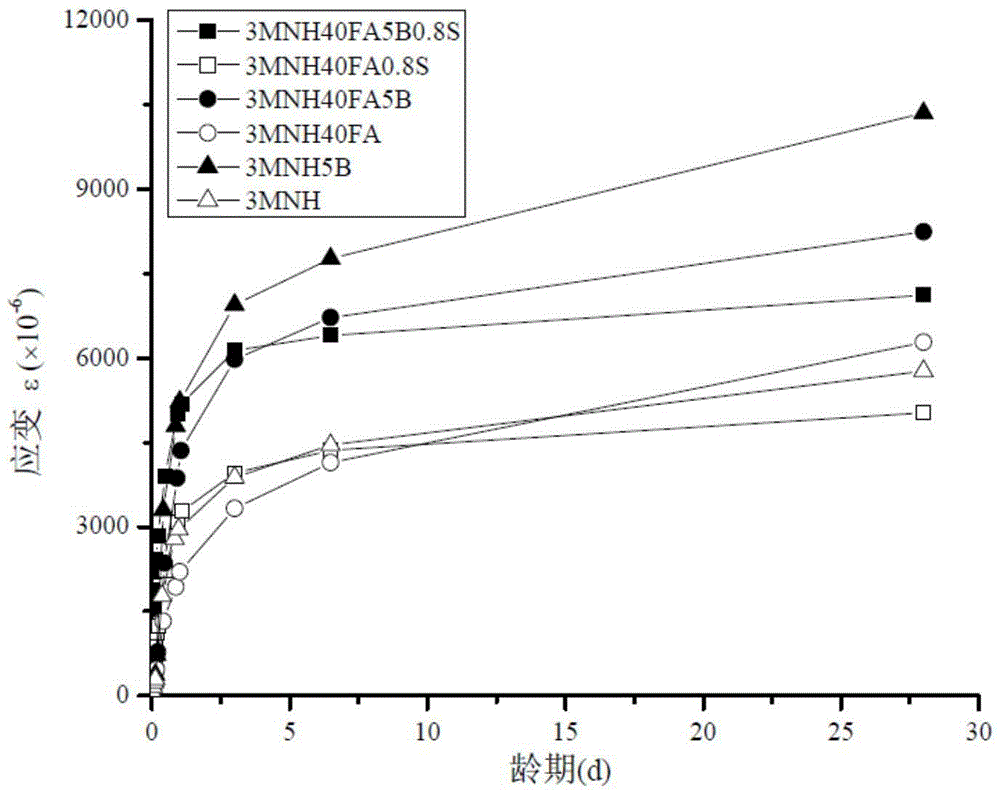

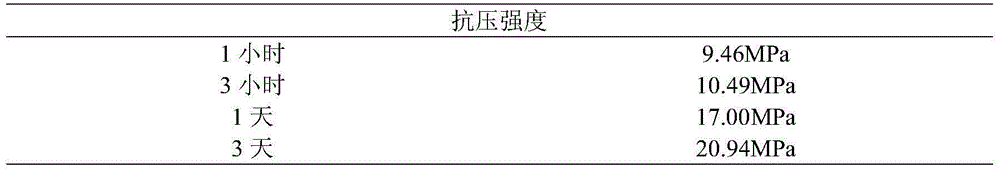

[0029] The sodium-magnesium phosphate cement-based material of the present invention comprises a mixed dry powder composed of dead-burned magnesium oxide, sodium dihydrogen phosphate, fly ash and setting retarder, wherein dead-burned magnesium oxide, sodium dihydrogen phosphate, fly ash, The weights of the retarders are 332g, 258g, 400g, and 10g, respectively. Water is added to the mixed dry powder, and the mixed dry powder and water are mixed in a weight ratio of 1000:150.

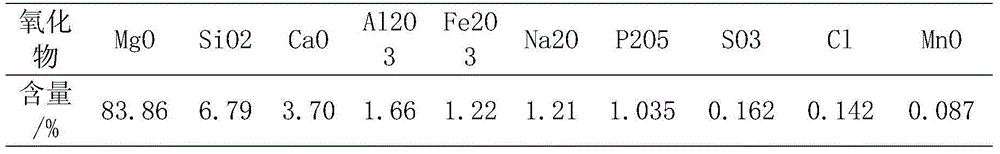

[0030] Phosphate provides an acidic environment and phosphate ions for the hydration reaction, and analytically pure sodium dihydrogen phosphate (NaH2PO4) is used; the retarder is used to adjust the setting time of sodium-magnesium phosphate cement, and analytically pure sodium tetraborate (Na2B4O7 10H2O) is used. . The dead-burned magnesia is obtained by calcining magnesite (MgCO3) at a high temperature of 1500°C, and its main chemical composition is shown in Table 1.

[0031] Table 1 Main chemical comp...

Embodiment 2

[0038] The sodium magnesium phosphate cement-based material of the present invention includes mixed dry powder and water, wherein the mixed dry powder is 268.42g of sodium dihydrogen phosphate, 315.79g of dead-burned magnesium oxide, 400g of fly ash, and 15.79g of retarder.

[0039] The preparation method is as follows: under the conditions of a temperature of 20±3°C and a relative humidity of (50±5)%, mixing and stirring dead-burning magnesium oxide, fly ash or the equivalent and a retarder for 1min, and then adding sodium dihydrogen phosphate to continue. Stir for 2 minutes, then add 150g of water and continue to stir for 2 minutes; pour the obtained slurry into the mold, shake it manually or on a vibrating table for 60 times, place it in an environment of 20±3°C, and remove the mold after coagulation for 30 minutes; the stirring machine is NJ- 160 type cement slurry mixer.

Embodiment 3

[0041] The sodium-magnesium phosphate cement-based material of the present invention comprises a mixed dry powder composed of sodium dihydrogen phosphate, dead-burned magnesium oxide, fly ash, and retarder, wherein sodium dihydrogen phosphate, dead-burned magnesium oxide, fly ash, The weight of the retarder is 340g, 400g, 330g, and 30g, respectively. Water is added to the mixed dry powder, and the mixed dry powder and water are mixed in a weight ratio of 1000:220.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com