Aquaculture water in-situ purification composite microbial membrane and using method thereof

A composite microorganism and aquaculture technology, which is applied in the field of in-situ purification of composite microbial membrane devices for aquaculture water bodies, can solve problems such as the fixation of microorganisms in water purification, and achieve the effects of no energy consumption, simple installation and maintenance, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

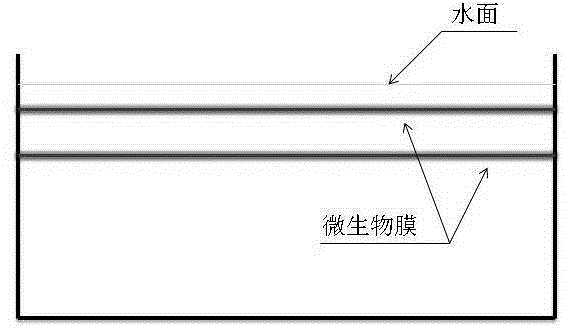

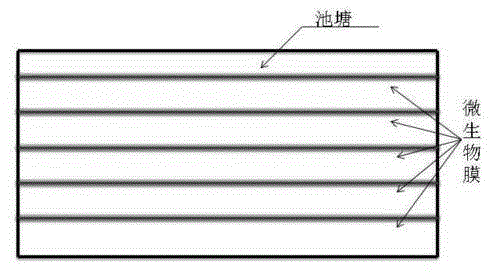

[0019] Example 1: Preparation and installation of composite microbial membrane for in-situ purification of aquaculture water

[0020] (1) The polypropylene bulky silk with large specific surface area is selected as the raw material, and the soft packing made of mechanical weaving is used as the immobilized carrier for water purification microorganisms.

[0021] (2) Prepare 2 parts of cultured Paenibacillus polymyxa bacteria solution, 3 parts of Lactobacillus plantarum bacteria solution, 3 parts of Rhodobacter sphaeroides bacteria solution, 2 parts of Rhodococcus pyridineophilus bacteria solution, 2 parts of Bacillus amyloliquefaciens bacteria solution Parts (the bacterial concentration of the selected bacterial solution is greater than 5×10 8 CPU / ml), after the bacteria solution is prepared, add 15 grams of food-grade konjac gum to each liter of the bacteria solution, and stir evenly to make a compound bacteria solution.

[0022] (3) Put the compound bacteria solution into t...

Embodiment 2

[0026] Example 2: In-Situ Purification of Aquaculture Water Body Composite Microbial Membrane Applied to Purify Aquaculture Water Body

[0027] The experimental base is located in the coastal area of Guangdong. Four high-level culture ponds of Penaeus vannamei (each pond covers an area of 3 mu and the depth of the pond is 2.5 meters) are divided into two control ponds without composite microbial film and two with composite microbial film. ponds, each pond puts 500,000 shrimp seedlings, and the breeding method is the same. The ammonia nitrogen content in the breeding water in the treatment pond can be stably controlled below 0.5 mg / L, and the nitrite nitrogen can be controlled below 0.8 mg / L; while the ammonia nitrogen content in the breeding water in the control pond fluctuates between 0.5 and 1.5 mg / L, and The higher the temperature, the greater the concentration of ammonia nitrogen, and the content of nitrite nitrogen fluctuates between 1.0 and 2.5 mg / L most of the time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com