Stirring machine

A technology of agitator and agitating shaft, which is applied to mixers, mixers, and dissolving directions with rotating mixing devices, can solve the problems of uneven mixing, low efficiency, long mixing time, etc., and achieves good mixing effect, energy saving, improved The effect of material dispersing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

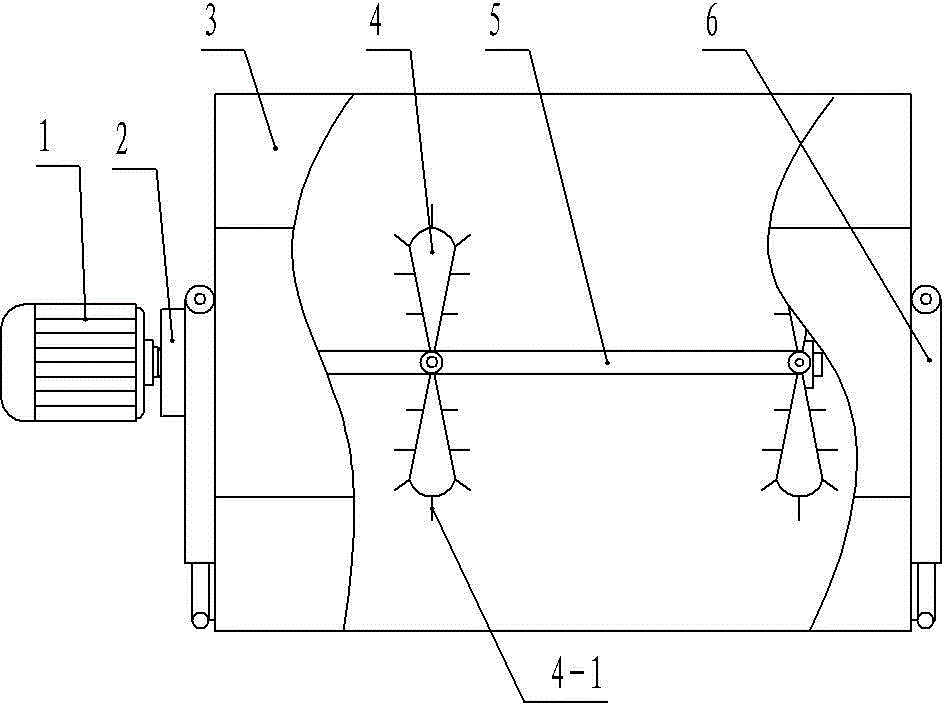

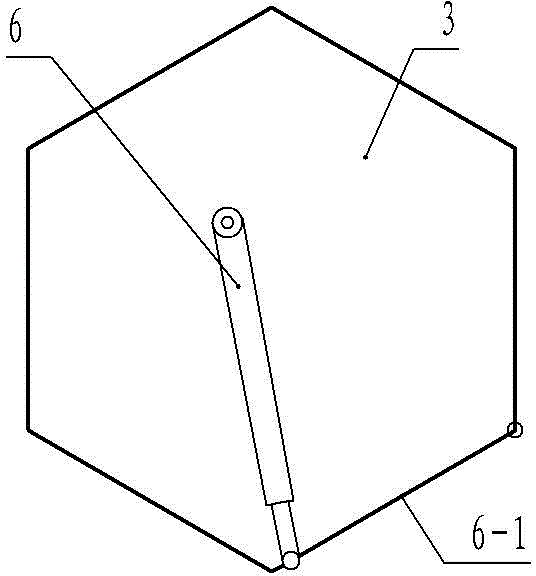

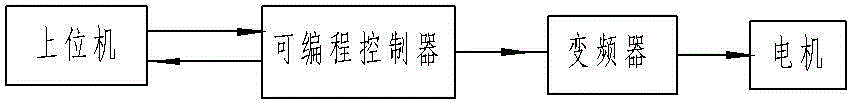

[0013] figure 1 , figure 2 , image 3 The shown mixer includes a stirring shaft 5 arranged in the housing 3, one end of the stirring shaft 5 is connected to the motor 1 through a reducer 2, two stirring blades 4 are installed on the stirring shaft 5, and multiple A stirring rod 4-1 with an angle of 45° to 135° to the stirring blade 4; a door 6-1 for material input or output is hinged on the shell 3, and two cylinders are respectively installed on both sides of the shell 3 6. Both sides of the openable end of the door 6-1 are respectively connected with the protruding end of the cylinder 6; the driving end of the motor 1 is connected with a frequency converter, and the control terminal of the frequency converter is connected with a programmable controller, and the programmable control connected to the host computer.

[0014] When working, the protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com