Winding tool for windings

A wire winding and tooling technology, applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve problems such as uneven winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

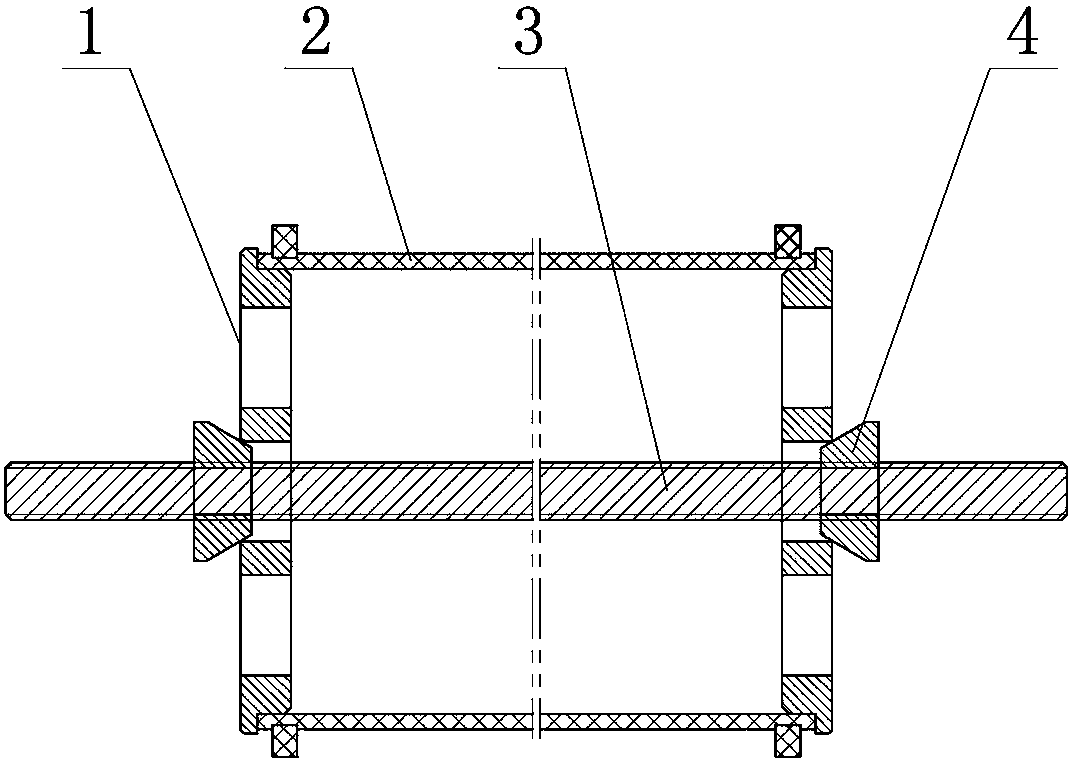

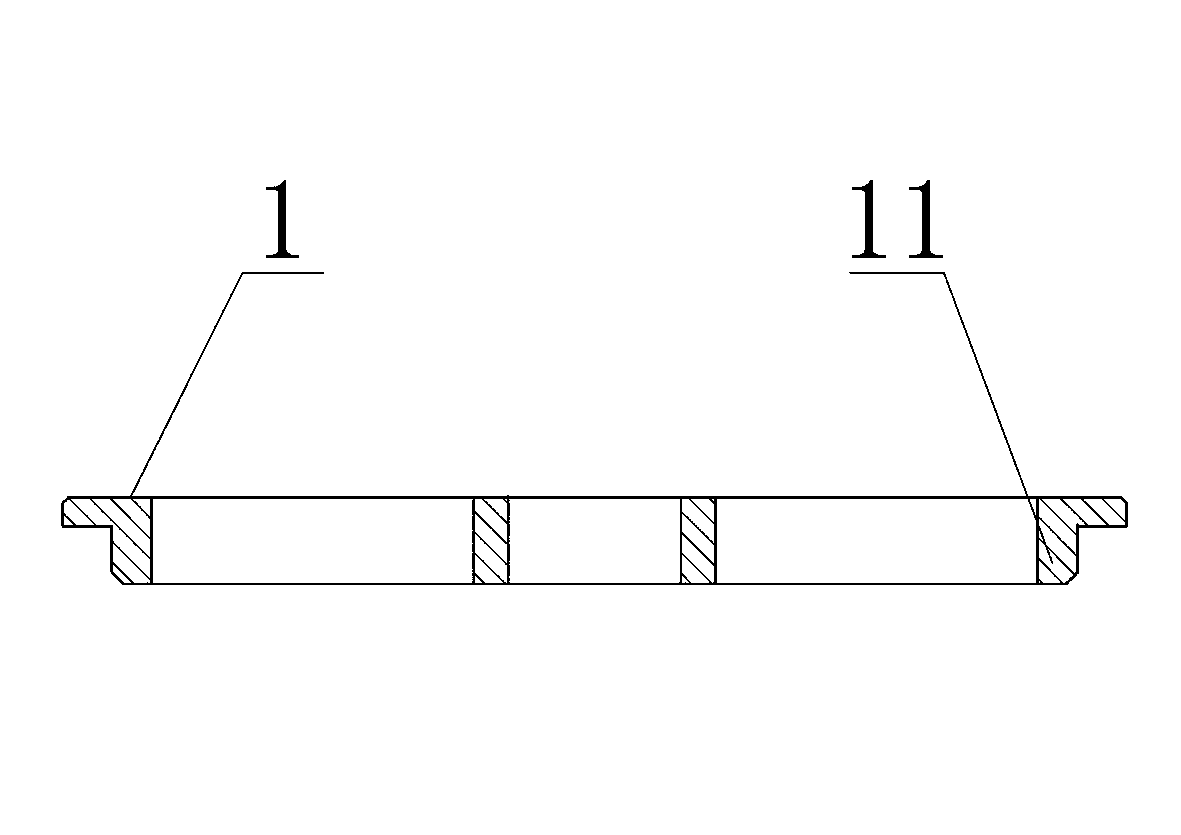

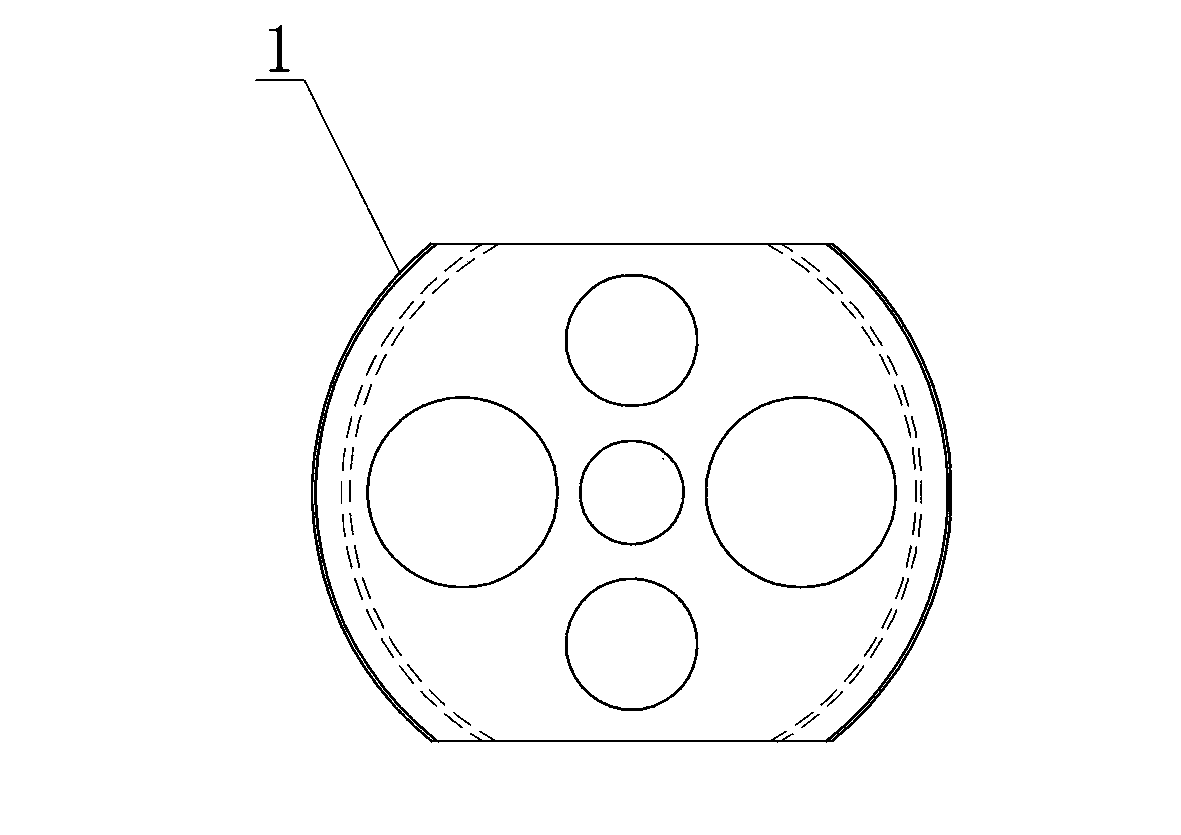

[0011] The embodiment of winding frock of the present invention: as Figure 1-3 As shown, the screw rod 3 is included, and the screw rod 3 is covered with two splints 1 arranged at intervals from left to right. Nut 4, lock nut 4 is a conical nut, and its outer peripheral surface is a conical surface, and the small diameter ends of the two lock nuts 4 are arranged oppositely, and the small diameter ends of the lock nut 4 go deep into the gap between the screw rod 3 and the corresponding clamping plate at the same time In the gap; when the conical surface of the lock nut 4 and the inner hole of the corresponding splint are pressed together, the coaxiality of the splint 1 and the screw rod 3 can be automatically realized, and the two lock nuts 4 can be screwed in the opposite direction, which can A force of relative movement along the axial direction of the screw rod 3 is applied to the two splints 1 . In this embodiment, the function of the two splints 1 is to clamp the insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com