Scanning head of scanning tunneling microscope

A scanning tunnel and scanning head technology, applied in scanning probe microscopy, scanning probe technology, measuring devices, etc., can solve the problems of inconvenient replacement of the mechanical arm and damage to the scanning head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

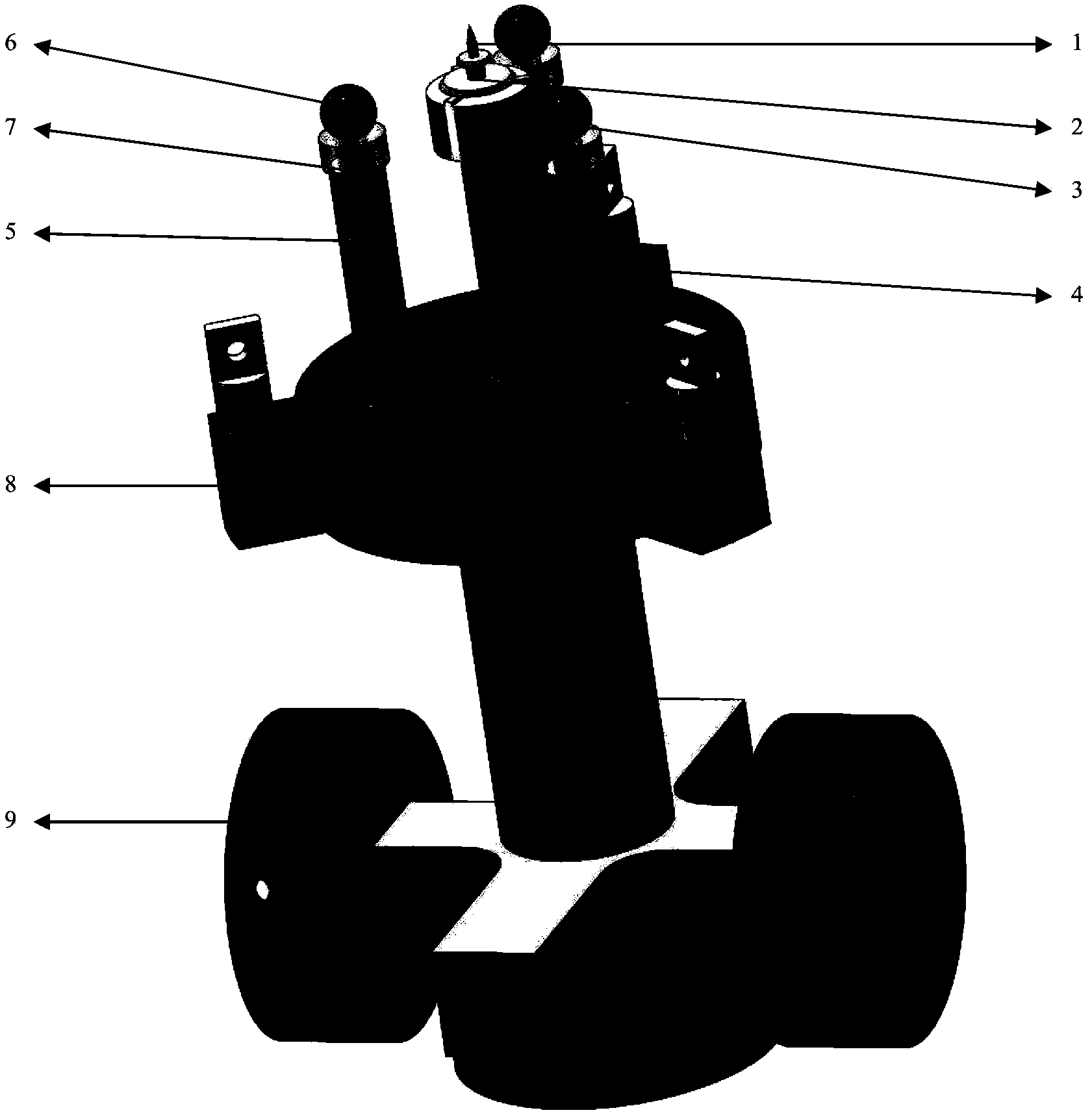

[0018] like figure 1 The illustrated embodiment shows a Besocke Type scanning tunneling microscope scan head according to the invention. The scanning head includes: needle point 1, needle point support 2, needle point support base 3, Z piezoelectric ceramic tube 4, X-Y piezoelectric ceramic tube 5 (only one of the three is labeled in the figure), tungsten ball 6 (in the figure Only one of the three is numbered), thick sapphire 7 (only one of the three is numbered in the figure), scanning head base 8, shock absorbing device 9.

[0019] Tip 1 is an electrochemically etched tungsten or silver tip.

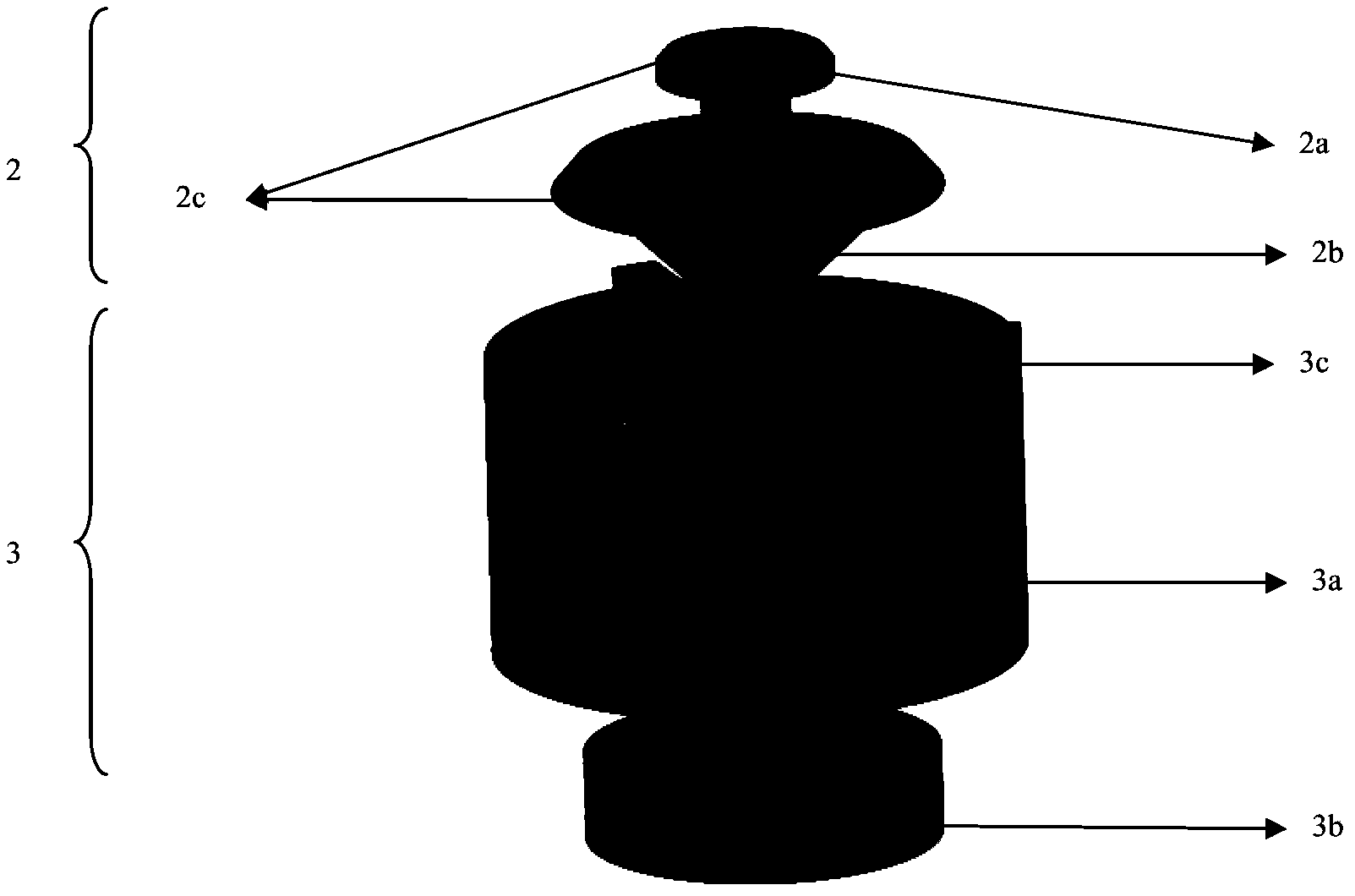

[0020] The needle point holder 2 is used to fix the needle point 1. In this embodiment, the needle point 1 is fixed to the cylindrical through hole 2a in the middle of the needle point holder 2 by conductive glue or solder (refer to figure 2 )middle. The needle point support 2 and the needle point support base 3 are detachable. The needle point support base 3 is glued on the Z p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com