A kind of pre-desulfurization method of high-sulfur bauxite

A high-sulfur bauxite and pre-desulfurization technology, applied in the field of metallurgy, can solve the problems of inability to be applied industrially, reduce the sulfur content of high-sulfur bauxite, and high-sulfur bauxite, and achieve simple operation, low operating temperature, and high energy efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

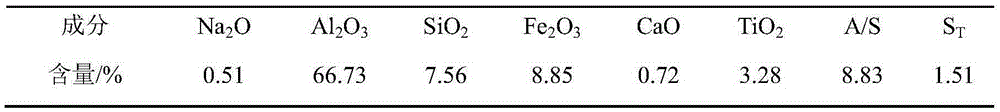

Embodiment 1

[0015] 80g sulfur content is 1.51% high sulfur bauxite, 400mL concentration is 150g / L (Na 2 (2 meter) sodium hydroxide solution is placed in the autoclave, sealed, heated and stirred, when the temperature reaches 150 ° C, feed oxygen, start timing, after 6 hours of reaction, cool down and go out of the still. The sulfur content in the desulfurized bauxite is 0.49%.

Embodiment 2

[0017] 80g sulfur content is 1.51% high sulfur bauxite, 400mL concentration is 150g / L (Na 2 (2 meter) sodium hydroxide solution is placed in the autoclave, sealed, heated and stirred, when the temperature reaches 180 ℃, feed oxygen, start timing, after reacting for 6 hours, cool down and go out of the still. The sulfur content in the desulfurized bauxite is 0.32%.

Embodiment 3

[0019] 80g sulfur content is 1.51% high-sulfur bauxite, 400mL concentration is 200g / L (Na 2 (2 meter) sodium hydroxide solution is placed in the autoclave, sealed, heated and stirred, when the temperature reaches 150 ° C, feed oxygen, start timing, after 6 hours of reaction, cool down and go out of the still. The sulfur content in the desulfurized bauxite is 0.50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com