A kind of graphene sheet with wrinkle and preparation method thereof

A graphene sheet and wrinkle technology, applied in the field of graphene sheet and its preparation, can solve the problems such as inability to generate wrinkles in the graphene sheet, and achieve the effects of easy operation and easy control of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method of generating wrinkles on a graphene sheet, said method comprising the steps of:

[0049] (1) After washing the silicon wafer with acetone and absolute ethanol, dry it with nitrogen for later use;

[0050] The weight average molecular weight is 100×10 3 Polystyrene is heated and dissolved in chlorobenzene to prepare a polystyrene solution with a mass concentration of 5%;

[0051] The polystyrene solution was spin-coated on the silicon wafer, and dried at 180°C to obtain a polystyrene layer with a thickness of 230nm;

[0052] (2) exfoliating the graphene onto the polystyrene-layered silicon wafer obtained in step (1) using a micromechanical force exfoliation method;

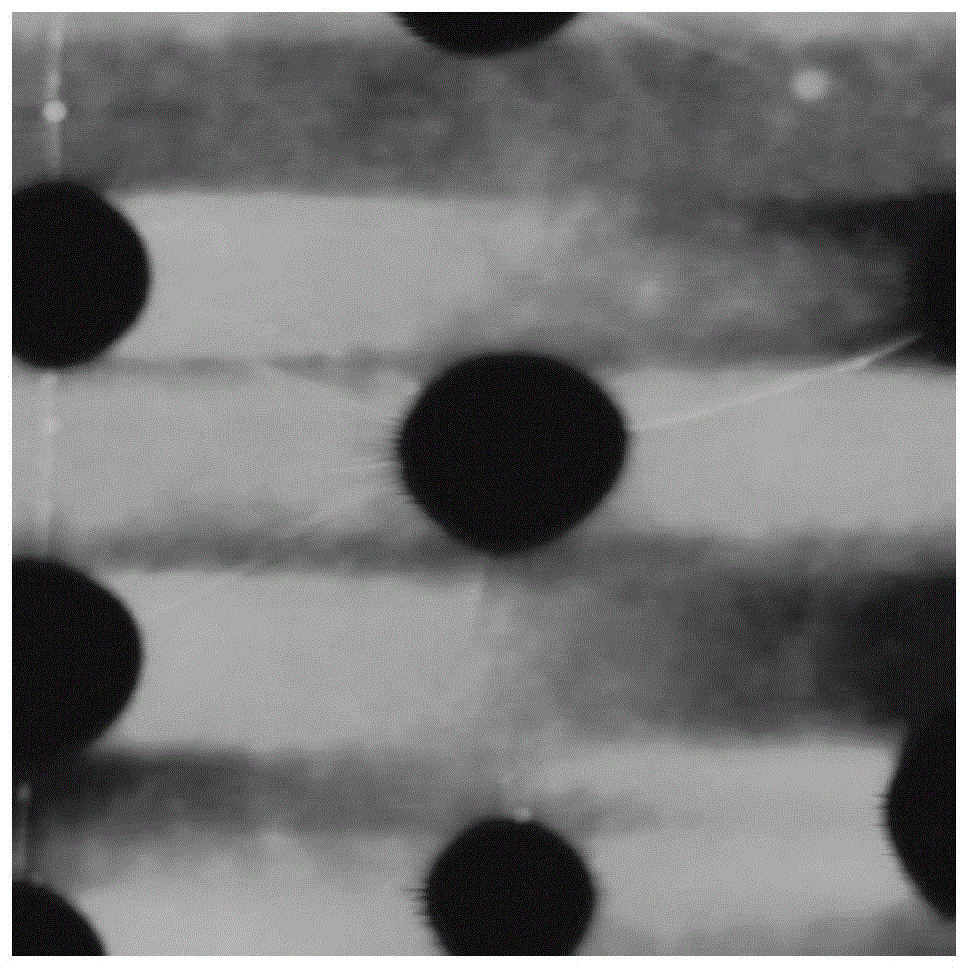

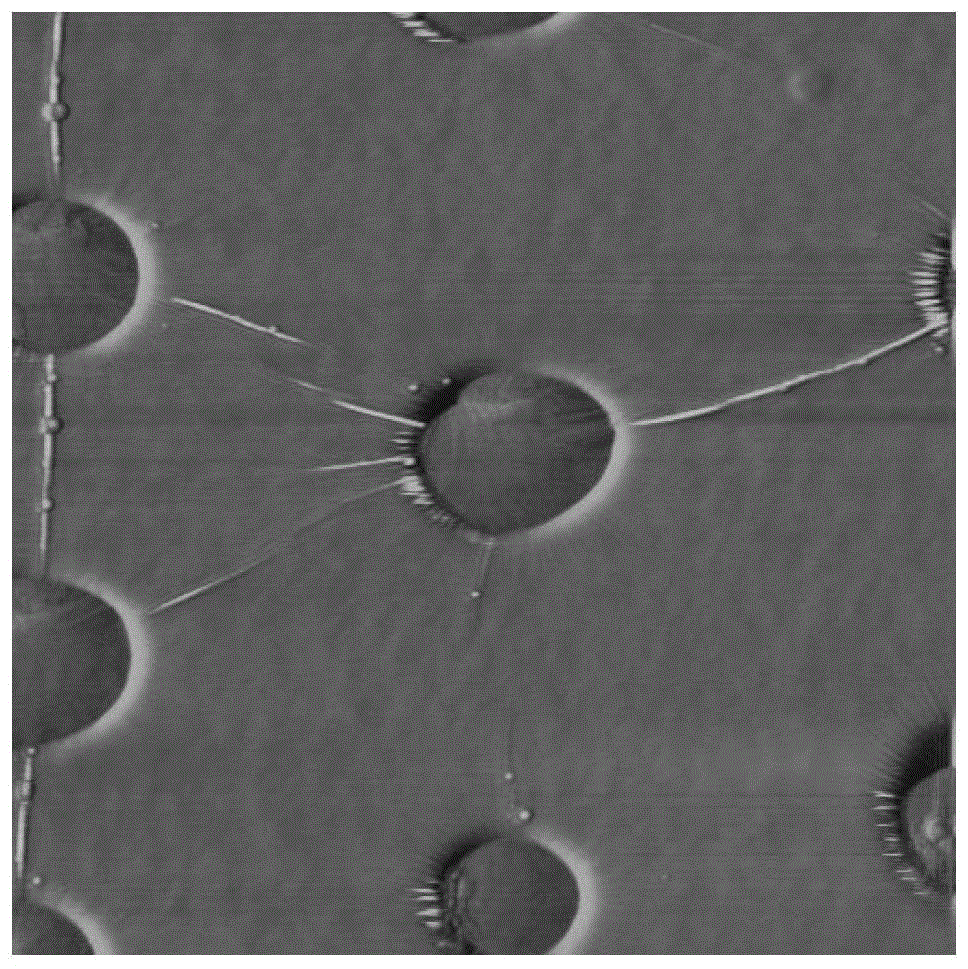

[0053] (3) Place the silicon wafer loaded with graphene sheets under the laser optical system (Renishaw inVia laser Raman spectrometer) with an optical microscope, find the position of the graphene sheets through the optical microscope, and then use the wavelength of 514nm laser irradiates the g...

Embodiment 2

[0057] The difference with embodiment 1 is:

[0058] The weight-average molecular weight of polystyrene used in step (1) is 600×10 3 , the mass concentration of the prepared polystyrene solution is 3%; the thickness of the polystyrene layer is 150nm;

[0059] The wavelength of the laser used in step (3) is 633nm, the laser power is 10mW, and the laser irradiation time is 20s.

Embodiment 3

[0061] The difference with embodiment 1 is:

[0062] The weight-average molecular weight of polystyrene used in step (1) is 900×10 3 , the mass concentration of the prepared polystyrene solution is 8%; the thickness of the polystyrene layer is 460nm;

[0063] The wavelength of the laser used in step (3) is 785nm, the laser power is 15mW, and the irradiation time is 90s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com