Head-free cylinder positioner

The technology of a positioner and a cylinder body is applied in the field of a headless cylinder body positioner, which can solve the problems of low reliability of the cylinder body inversion scheme, and achieve the effect of avoiding bumps and scratches and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. For convenience of description, the sizes of different layers and regions are enlarged or reduced, so the sizes and ratios shown in the drawings do not necessarily represent actual sizes, nor do they reflect the proportional relationship of sizes.

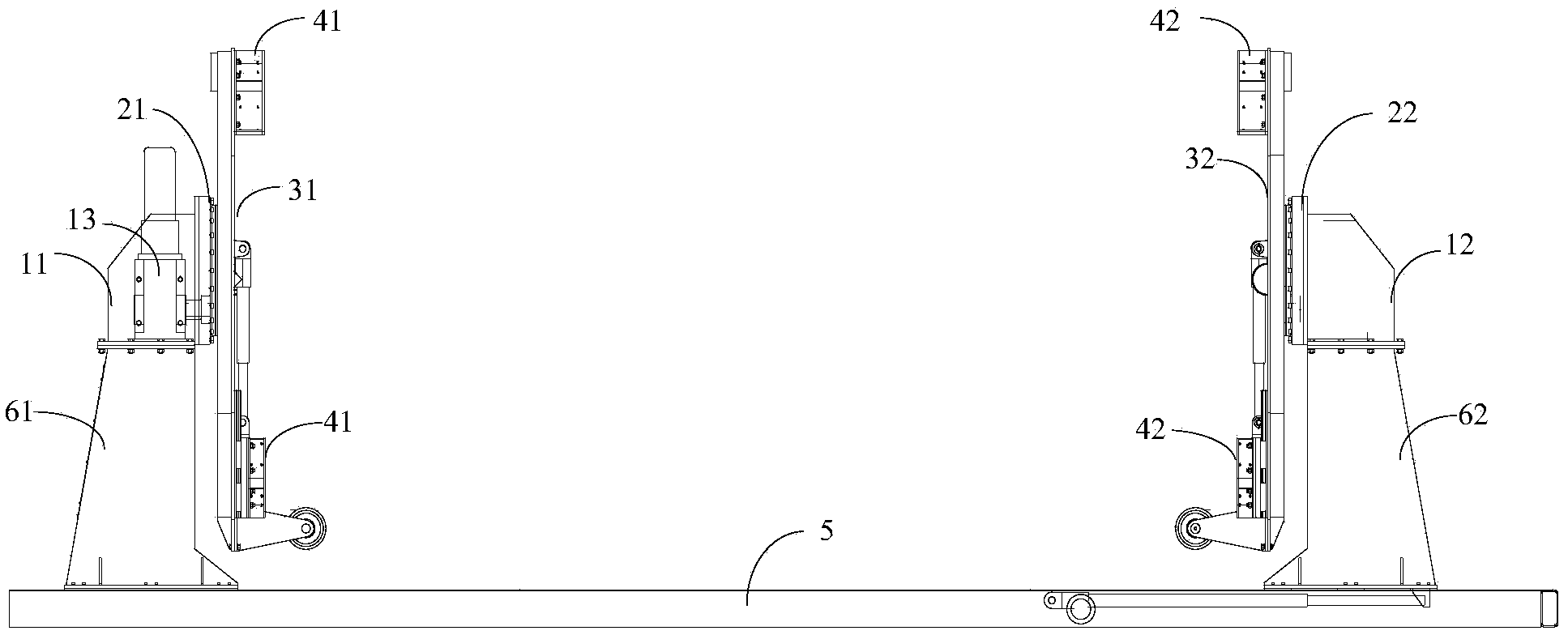

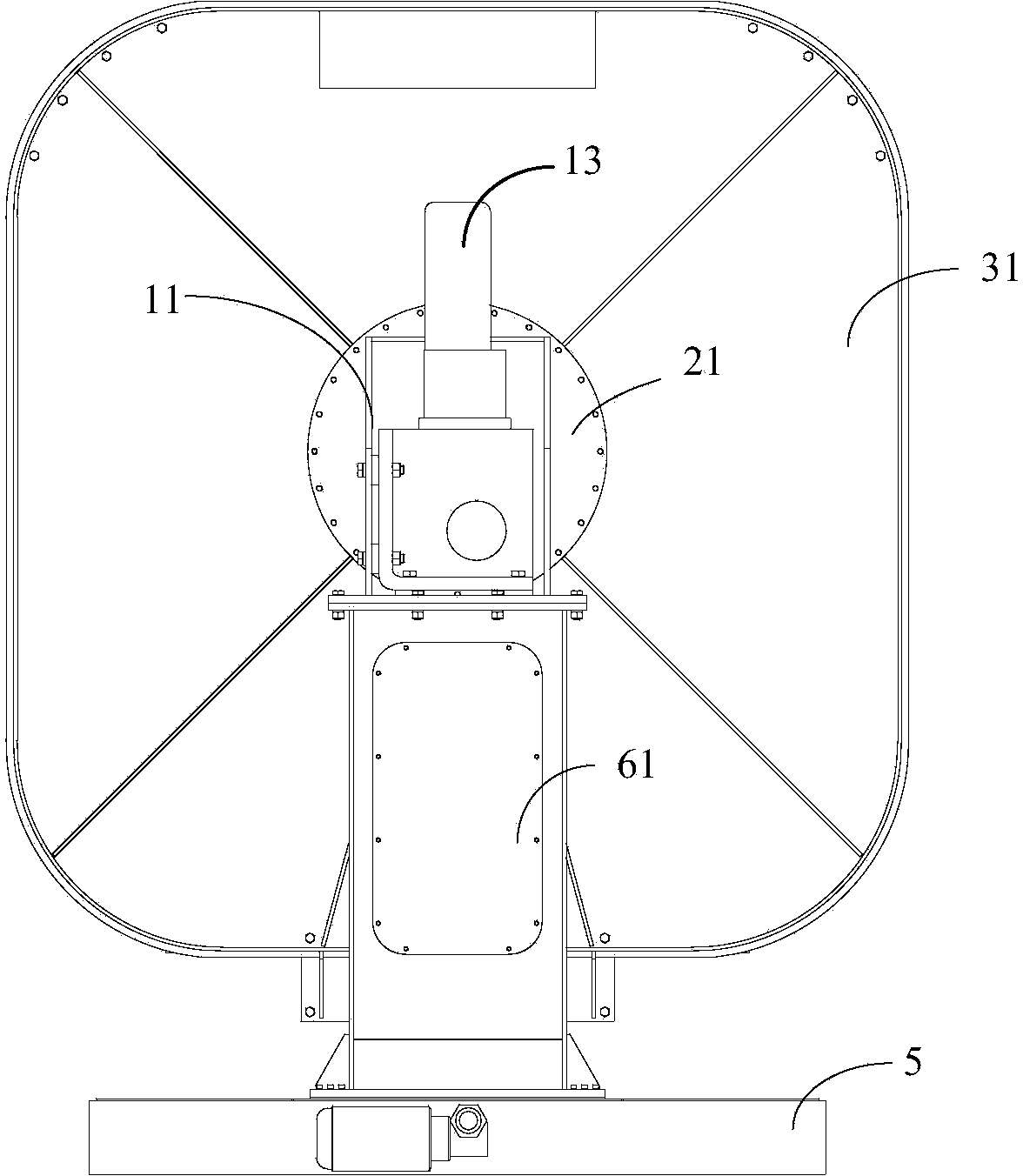

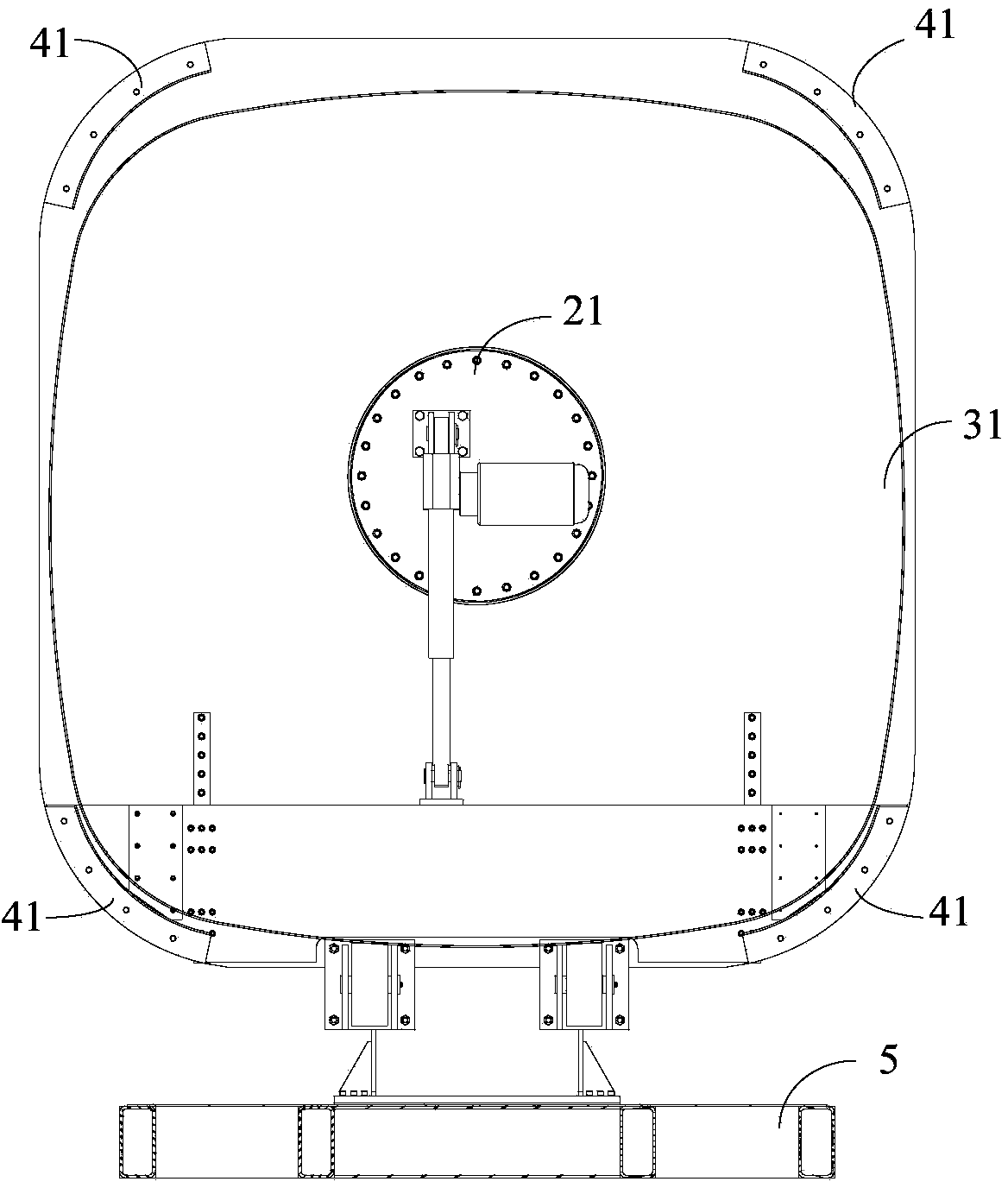

[0029] figure 1 A schematic diagram of the side view structure of the headless cylinder displacer provided for the embodiment of the present invention, as shown in figure 1 As shown, the shifter includes: a first slewing support seat 11 and a second slewing support seat 12 oppositely arranged, a motor reducer 13 arranged on the first slewing support seat 11 and a first slewing support 21 , the second slewing bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com