Method for producing patch, patch and package

A manufacturing method and patch technology, applied in the field of patch manufacturing method, patch and packaging, can solve the problem of insufficient skin permeability of ropinirole, insufficient stability of ropinirole over time, etc. problem, to achieve the effect of inhibiting crystal growth and maintaining it for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0154] First, 15.0 parts by mass (13.2 parts by mass in conversion to ropinirole hydrochloride) of ropinirole hydrochloride, 1.6 parts by mass of sodium hydroxide (a desalting agent, 0.8 parts by mass relative to 1 mole of ropinirole hydrochloride) were mixed using a mixer. mol), 11.9 parts by mass of liquid paraffin, toluene (solvent), 11.4 parts by mass of styrene-isoprene-styrene block copolymer (SIS) (SIS5000, produced by JSR), 42.6 parts by mass of alicyclic hydrocarbon resin , 4.5 parts by mass of polyisobutylene, 10.0 parts by mass of isopropyl palmitate, and 3.0 parts by mass of octyldodecanol were mixed to prepare 100 parts by mass (mass of the total amount of the compound excluding the solvent (toluene)) adhesive layer composition. Table 1 shows the composition (excluding toluene) of the aforementioned pressure-sensitive adhesive layer composition. In addition, with regard to the molar ratio of ropinirole hydrochloride and sodium hydroxide, the aforementioned adhesi...

Embodiment 2~12

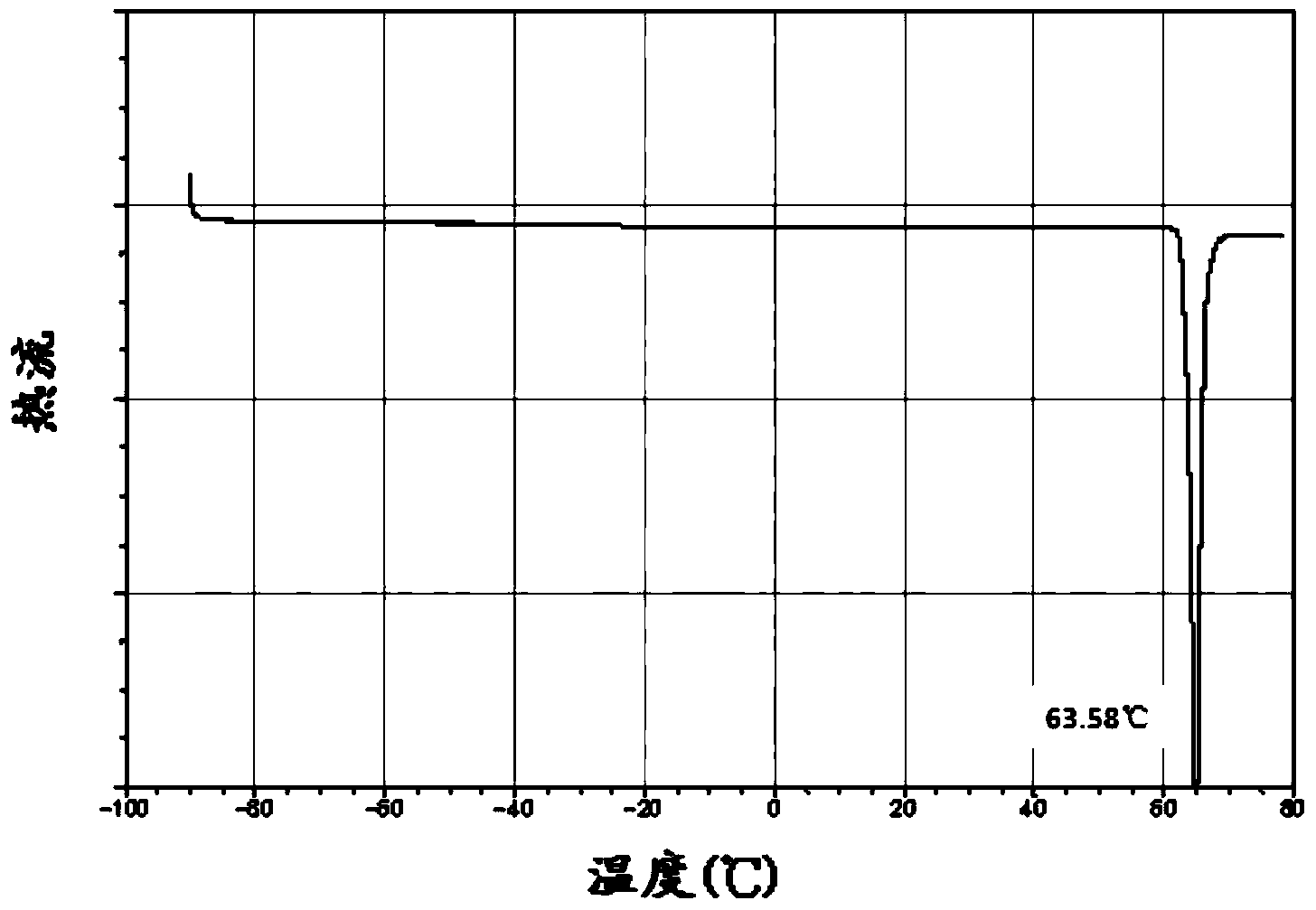

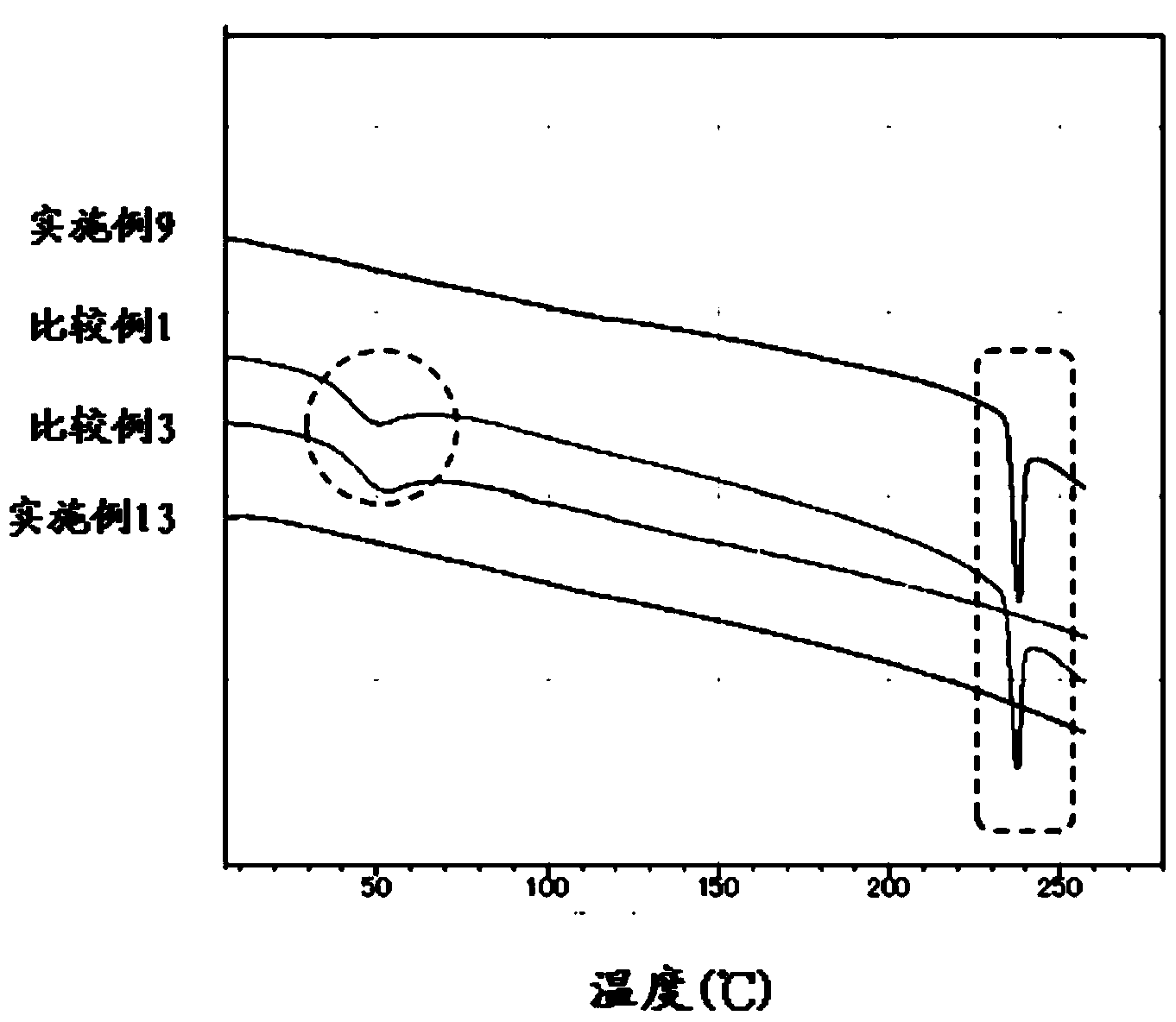

[0158] Patch preparations were obtained in the same manner as in Example 1, except that the heat treatment conditions were set to the conditions shown in Table 2. As a result of the evaluation of the above-mentioned free body crystals and salt crystals on the patches immediately after manufacture, it was confirmed that the evaluation of free body crystals was A and the evaluation of salt crystals was B in both patches, although ropihydrochloride remained Nile crystals, but ropinirole free form is contained in the adhesive layer in a supersaturated concentration and in dissolved form. A graph showing the results of DSC measurement of the patch obtained in Example 9 immediately after manufacture is at figure 2 shown in .

Embodiment 13

[0160] First, it was obtained in the same manner as in Example 1, except that it had the composition shown in Table 1 and that the amount of sodium hydroxide added was 1.1 moles relative to 1 mole of ropinirole hydrochloride. Adhesive layer composition. In addition, in the above-mentioned molar ratio of ropinirole hydrochloride to sodium hydroxide, the adhesive layer composition does not contain ropinirole hydrochloride but contains 13.2 parts by mass of free ropinirole. In addition, the amount of free ropinirole at this time is an amount having a supersaturated concentration with respect to the aforementioned pressure-sensitive adhesive layer composition (excluding the solvent).

[0161] Then, using the obtained pressure-sensitive adhesive layer composition, except that the heat treatment conditions were the conditions shown in Table 2, it carried out similarly to Example 1, and obtained the patch. As a result of the evaluation of the above-mentioned free body crystals and sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com