Bundling machine for picking up straws and plastic film residues

A technology for a baler and straw, which is applied to the field of dual-purpose picking and baling machines for straw residue and film, can solve the problems of inability to popularize and apply in a large area, poor operation effect, and high mechanical cost, and achieves clean residue film picking, high operation efficiency, and high efficiency. The effect of a large amount of job feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

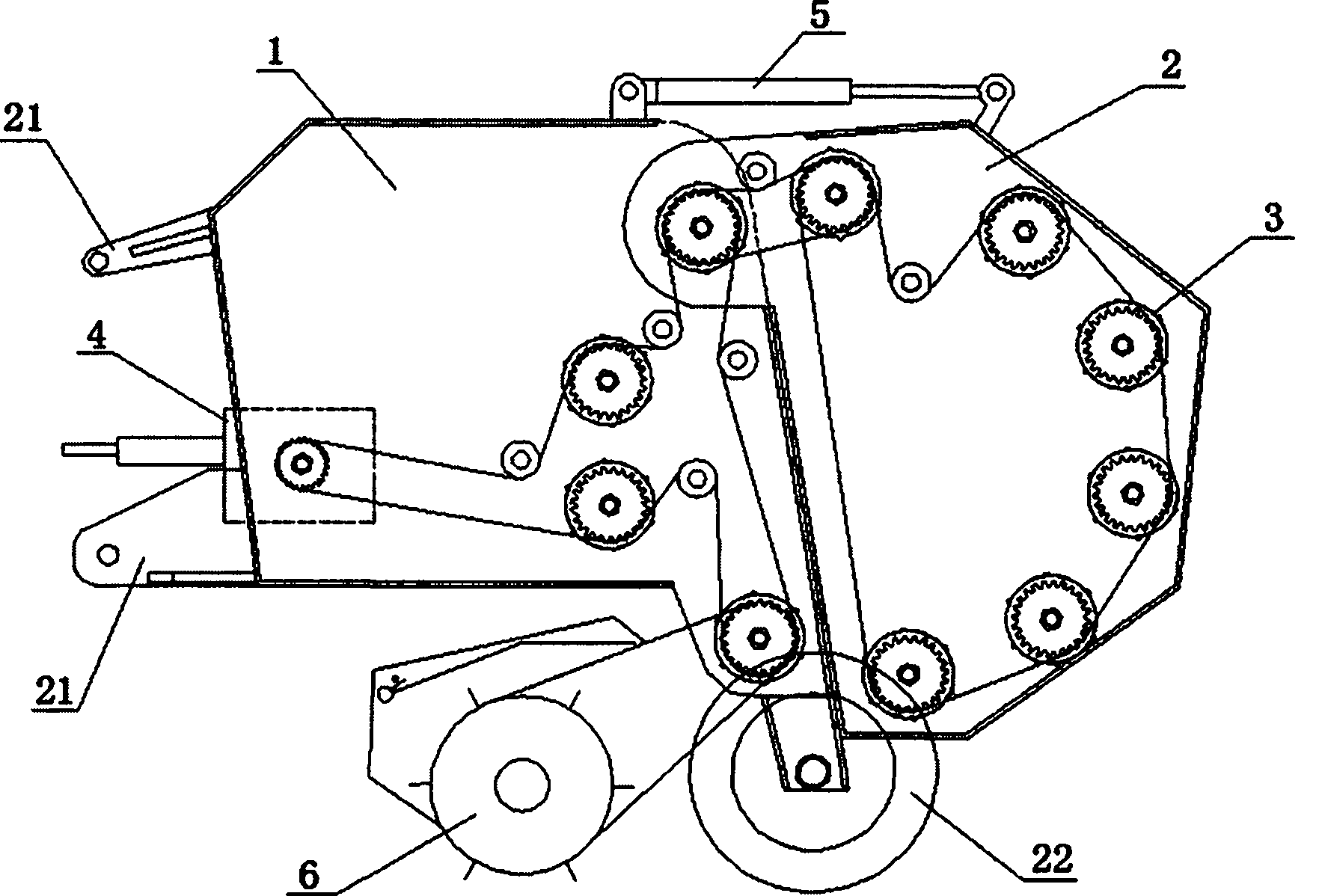

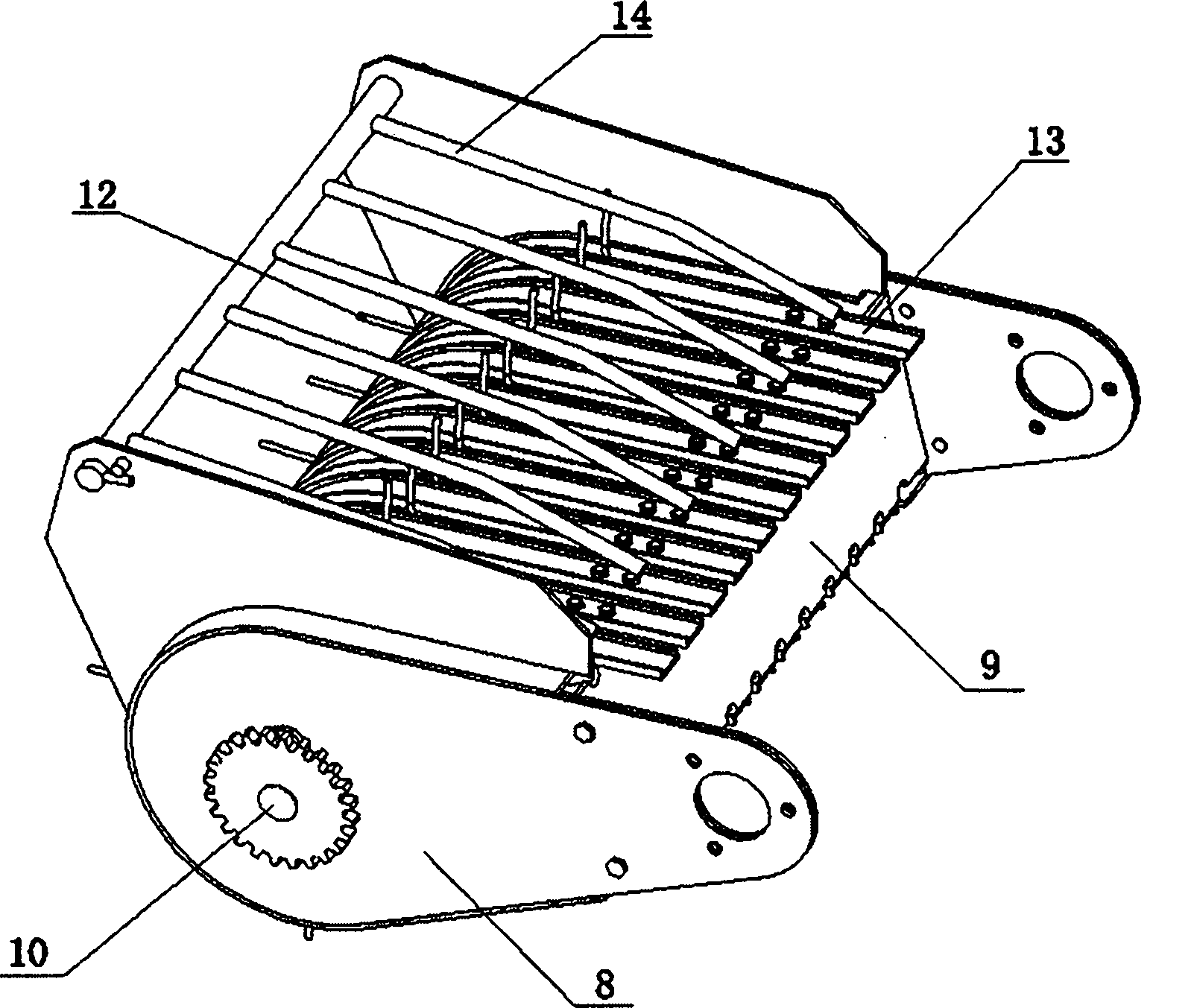

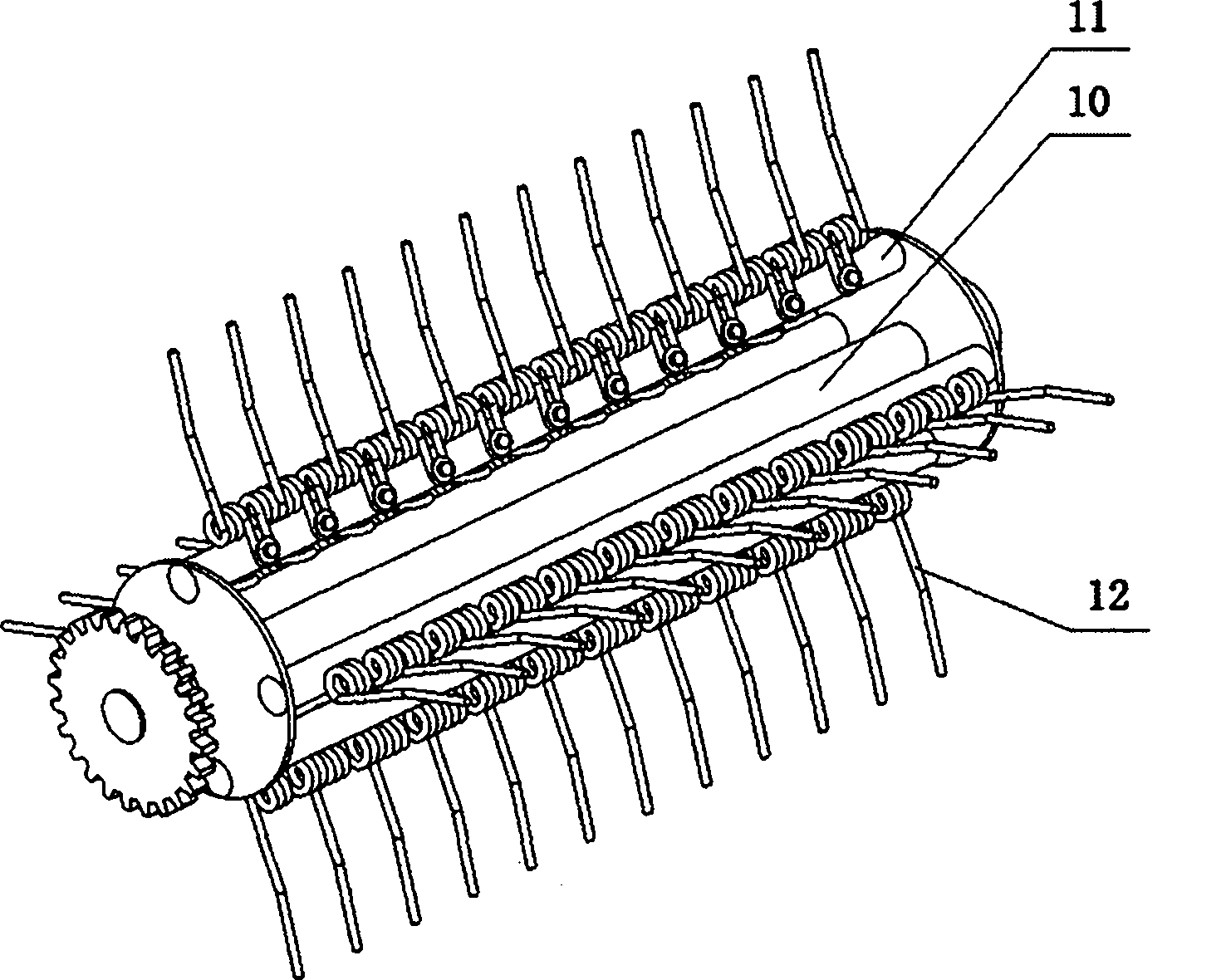

[0027] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, a straw residue film dual-purpose picking and bundling machine includes a body, a picker and a power transmission mechanism; the body is composed of a front body 1 and a rear body 2 hinged together, and the front body 1 and the rear body 2 Ten bundling rollers 3 are arranged in an upper ring, and ten bundling rollers 3 enclose a bundling room; the power transmission mechanism includes a gearbox 4 driven by a locomotive, and the gearbox 4 drives each bundling roller 3 through a chain Rotate and work with the picker, install the hydraulic cylinder 5 that drives the opening and closing of the baling chamber between the front body 1 and the rear body 2; the picker is the straw picker 6 installed at the bottom of the front body. The straw picker includes two end covers 8, a connecting plate 9 and an elastic tooth shaft 10 are installed between the two end covers 8, an elastic tooth frame 11 is fixedly installed o...

Embodiment 2

[0028] Embodiment 2: as Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a straw residue film dual-purpose picking and bundling machine includes a body, a picker and a power transmission mechanism; the body is composed of a front body 1 and a rear body 2 hinged together, and the front body 1 and the rear body 2 Ten bundling rollers 3 are arranged in an upper ring, and ten bundling rollers 3 enclose a bundling room; the power transmission mechanism includes a gearbox 4 driven by a locomotive, and the gearbox 4 drives each bundling roller 3 through a chain Rotate and work with pick-up, the hydraulic oil cylinder 5 that drives baling chamber opening and closing is installed between front body 1 and rear body 2; Described pick-up is the residual film pick-up 7 that is installed in front body bottom. The residual film picker includes a drum 15 that is driven to rotate by a power transmission mechanism, and a fixed shaft 16 that is eccentric to the lower side is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com