Method and device for filling raw ceramic through holes with metal paste

A technology of metal paste and filling method, applied in the direction of forming the electrical connection of printing elements, can solve the problems of high cost, complicated operation, low efficiency, etc., and achieve the effects of improving production efficiency, simple operation and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

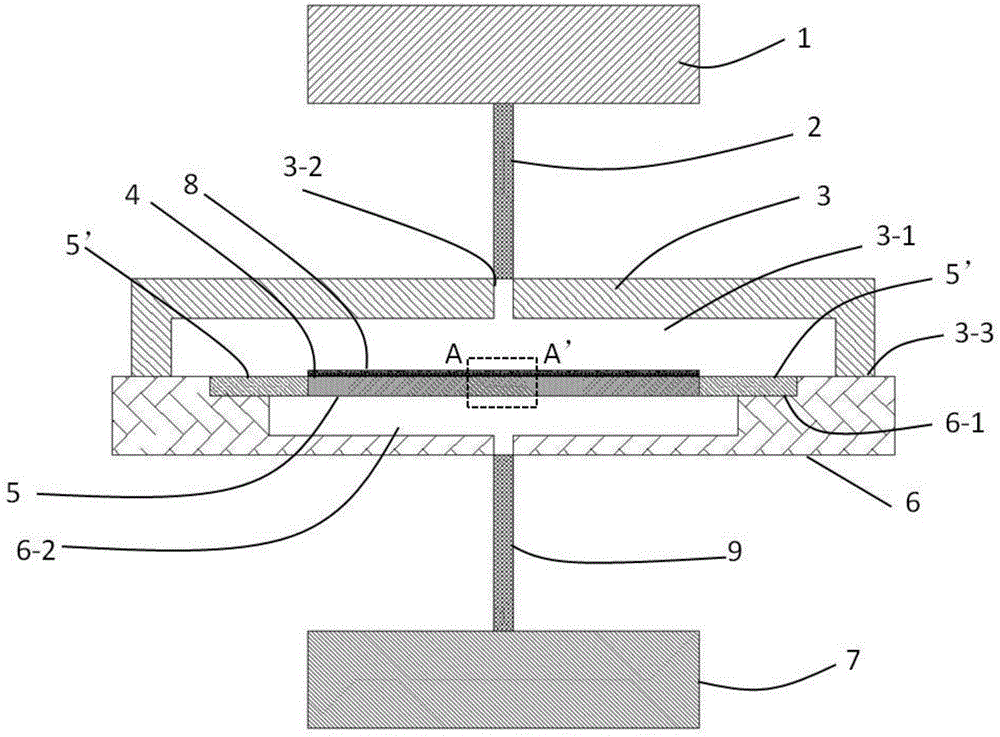

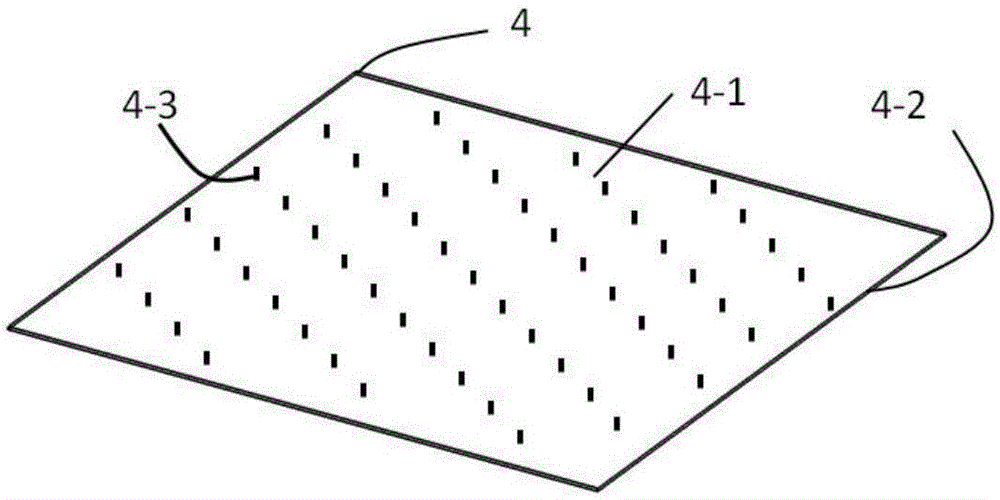

[0026] The device of this embodiment is as figure 1 As shown, it includes a hole filling pressure generating device 1, a first gas line 2, a pressurized sealing device 3, a green ceramic tape 4, a hole filling slurry 8, a gas-permeable flat plate 5, a metal bracket 6, and a second gas line 9. Vacuum generating device 7. Its section is as figure 2 as shown, image 3 Yes figure 2 Partial cross-sectional view of region A-A' in Fig.

[0027] The pressure generating device 1 is airtightly connected to the first gas circuit interface 2-1 through the interface 1-1, and at the same time, the other end interface 2-2 of the first gas circuit is connected to the gas circuit interface 3 of the pressurized sealing device -2 achieves a sealed connection. 3-1 in the pressurized sealing device is an air cavity, which provides space for placing raw porcelain and slurry, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com