Three dimensional gradient metal hydroxide/oxide electrode material and manufacture method and application thereof

A technology of hydroxide and electrode materials, applied in electrode manufacturing, hybrid/electric double layer capacitor manufacturing, nanotechnology for materials and surface science, etc., can solve poor conductivity and ion dynamics, cycle performance and rate Poor performance, limited practical application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

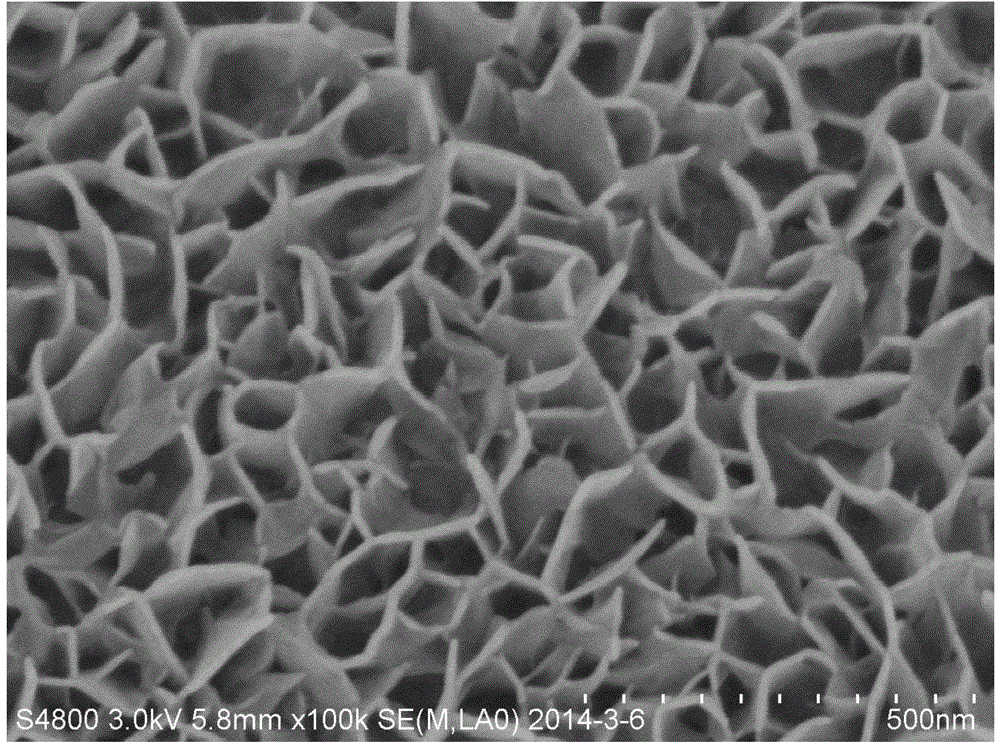

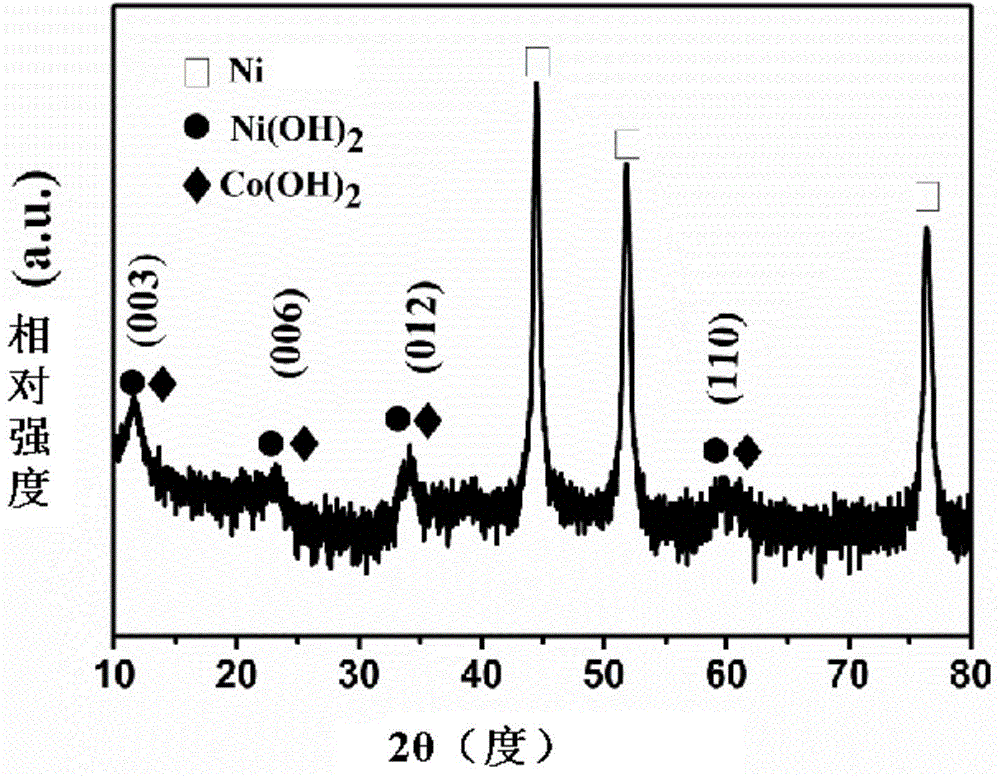

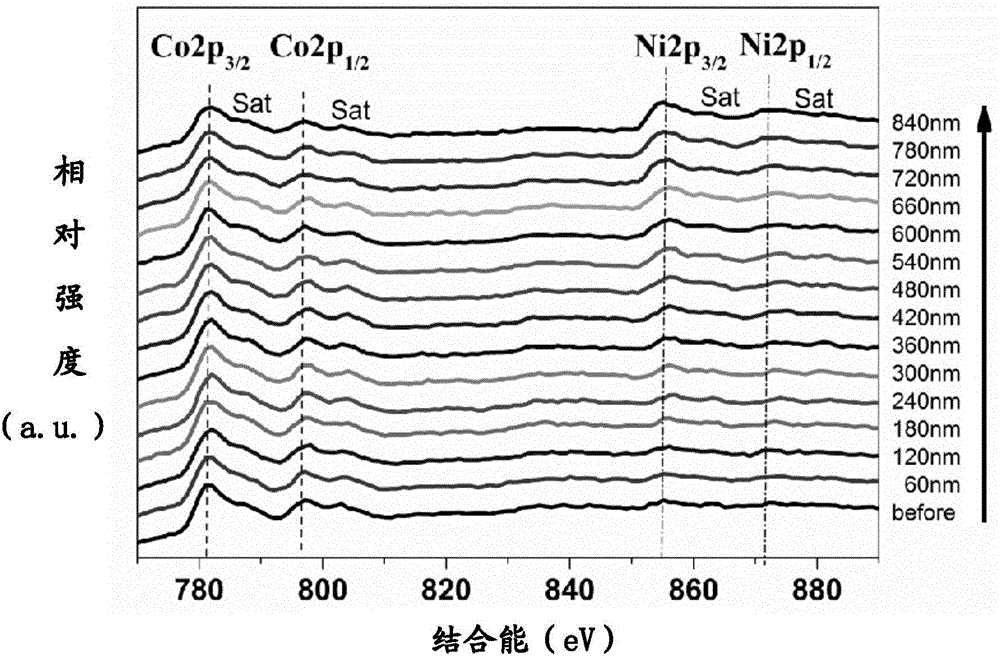

[0197] This embodiment provides a preparation method of a three-dimensional gradient metal hydroxide / oxide electrode material, comprising the following steps:

[0198] According to Ni 2+ :Co 2+ The molar concentration ratios are 1:0, 2:1, 1:1, 1:2, and 0:1, and 5 parts of nitrate solutions with a total concentration of metal ions of 0.01mol / L are prepared; the nickel foam is cut into 1×1cm 2 size, and ultrasonicated by 3mol / L hydrochloric acid solution for 10 minutes to remove the oxide film on the surface, and then washed three times with deionized water and absolute ethanol in sequence; the treated foamed nickel was used as the working electrode, saturated calomel and platinum As the reference electrode and the counter electrode respectively, the three-electrode system was assembled, and the constant current was 0.0005A on the CHI660E electrochemical workstation, followed by Ni 2+ :Co 2+ In the nitrate solution with a molar ratio of 1:0, 2:1, 1:1, 1:2, and 0:1, electrode...

Embodiment 2

[0226] This embodiment provides a preparation method of a three-dimensional gradient metal hydroxide / oxide electrode material, comprising the following steps:

[0227] According to Ni 2+ :Co 2+ The molar concentration ratios are 4:1, 3:1, 2:1, and 1:1 respectively, and four sulfate solutions with a total metal ion concentration of 0.02mol / L are prepared; the copper foam is cut into a diameter of 1.8 cm circular pole piece, and ultrasonicated with 3mol / L hydrochloric acid solution for 10 minutes to remove the oxide film on the surface, and then washed three times with deionized water and absolute ethanol in sequence; the treated foam copper was used as the working electrode, Saturated calomel and platinum sheets were used as reference electrode and counter electrode respectively, and a three-electrode system was assembled, and the constant current was 0.001A on the CHI660E electrochemical workstation, followed by 2+ :Co 2+ In the nitrate solution with a molar ratio of 4:1, 3...

Embodiment 3

[0230] This embodiment provides a preparation method of a three-dimensional gradient metal hydroxide / oxide electrode material, comprising the following steps:

[0231] According to Ni 2+ :Co 2+ The molar ratios are 4:1, 3:1, 2:1, and 1:1, and 4 chloride salt solutions with a total metal ion concentration of 0.02mol / L are configured; the copper foam is cut into a diameter of 1.8 cm circular pole piece, and ultrasonicated with 3mol / L hydrochloric acid solution for 10 minutes to remove the oxide film on the surface, and then washed three times with deionized water and absolute ethanol in sequence; the treated foam copper was used as the working electrode, Saturated calomel and platinum sheets were used as reference electrode and counter electrode respectively, and a three-electrode system was assembled, and the constant current was 0.001A on the CHI660E electrochemical workstation, followed by 2+ :Co 2+ In the nitrate solution with a molar ratio of 4:1, 3:1, 2:1, and 1:1, elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com