Operating mechanism and circuit breaker using the same

An operating mechanism and circuit breaker technology, which is applied to contact drive mechanisms and other directions, can solve the problems that the output torque of the drive motor cannot adapt to the three-phase circuit breaker, the increase in the manufacturing cost of the drive motor, and the increase in the quality of the transmission system by the connecting rod. The effect of reducing the size and weight of the structure, convenient layout, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

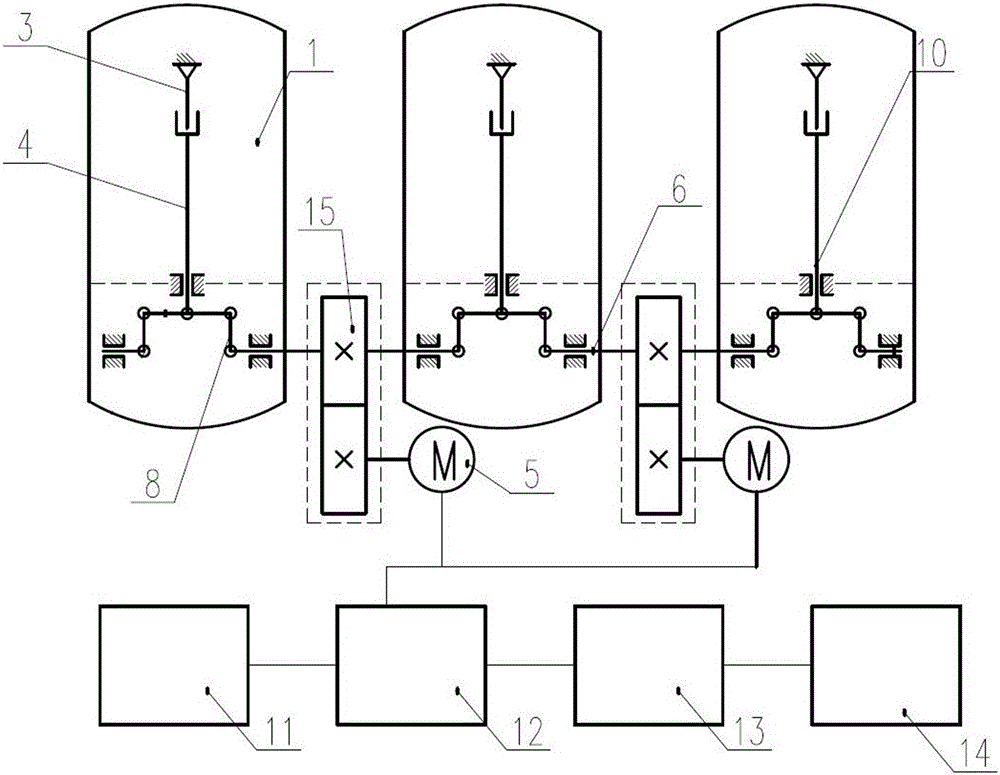

[0021] An example of a circuit breaker is Figure 2~3 As shown: the circuit breaker in this embodiment is an open circuit breaker, including the operating mechanism and the contact assembly 1 arranged side by side at intervals of three phases. Each contact assembly includes a static contact 3 and a branch with a moving contact 4. Closing lever 10, the operating mechanism includes a left brake lever transmission structure, a middle brake lever transmission structure and a right brake lever transmission structure respectively driving the reciprocating movement of the corresponding phase opening and closing levers, and the left, middle and right brake lever transmission structures are all The crankshaft 8 is connected by the interphase connecting rod 6 between two adjacent brake lever transmission structures. The operating mechanism also includes two drive motors 5 symmetrically arranged on the left and right sides of the middle brake lever transmission structure. The drive motors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com