Loom teaching aid

A technology of looms and teaching aids, applied in the field of teaching aids, can solve the problems of large size, inability to move independently of the mechanism, and difficulty in handling, so as to achieve the effect of easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

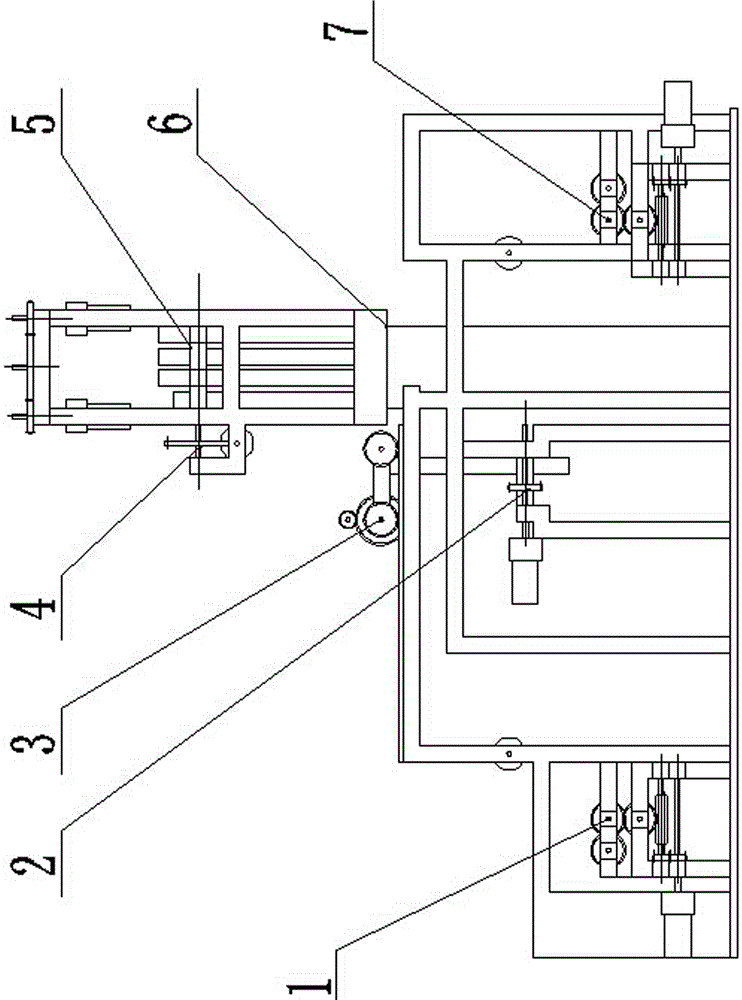

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , Figure 9 and Figure 10 The loom teaching aid of the present embodiment shown is, from front to back, a crimping mechanism 1, a weft insertion mechanism 2, a weft beating mechanism 3, an opening mechanism 6, and a let-off mechanism 7. The crimping mechanism 1, weft insertion mechanism 2, beating mechanism The weft mechanism 3, the shedding mechanism 6 and the warp let-off mechanism 7 are respectively controlled by motors, and are all connected to the control board 58; the shedding mechanism 6 includes a heald selection device 4 and a heald lifting device 5;

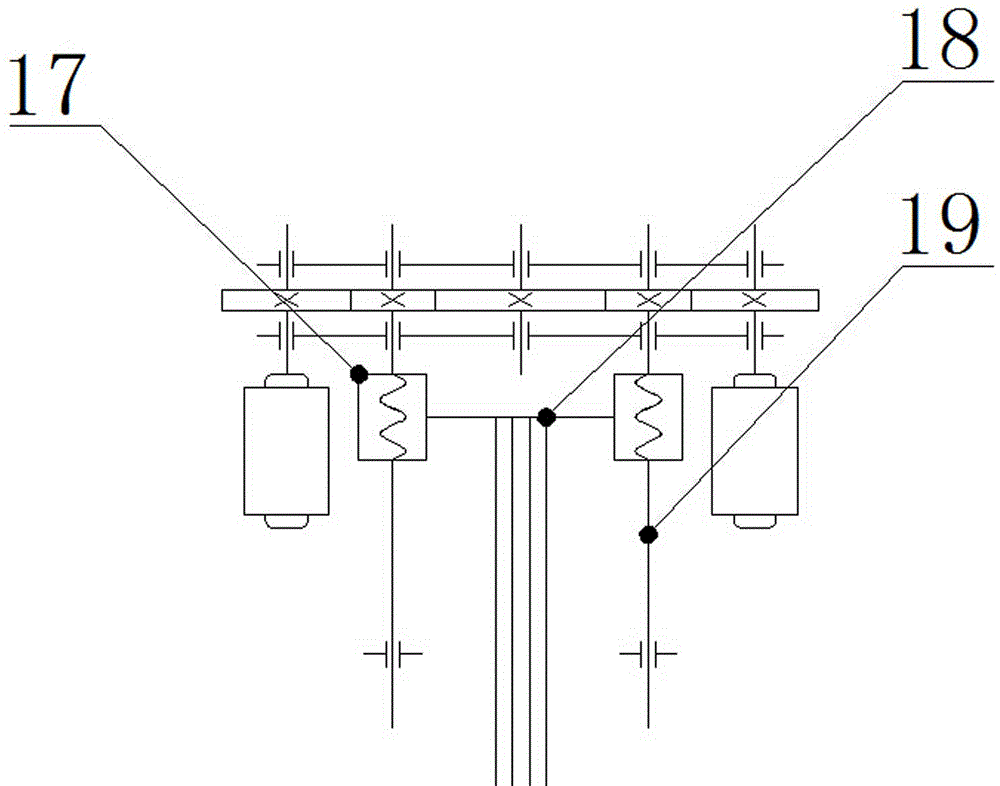

[0036] The selection device is composed of a motor I8, a bracket I12, a bracket II11, a worm wheel I14, a worm I16, a spike 15 and a pattern plate 13; the motor I8 is fixed on the bracket I12, and the bracket I12 is fixed in the middle of the bracket II11. The worm I16 is connected to the output shaft e...

Embodiment 2

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 The loom teaching aid of the present embodiment shown is, from front to back, a crimping mechanism 1, a weft insertion mechanism 2, a weft beating mechanism 3, an opening mechanism 6, and a let-off mechanism 7. The crimping mechanism 1, weft insertion mechanism 2, beating mechanism The weft mechanism 3, the shedding mechanism 6 and the warp let-off mechanism 7 are respectively controlled by motors, and are all connected to the control board 58; the shedding mechanism 6 includes the shed selection device 4 and the heald lifting device 5;

[0051] The selection device is composed of a motor I8, a bracket I12, a bracket II11, a worm wheel I14, a worm I16, a spike 15 and a pattern plate 13; the motor I8 is fixed on the bracket I12, and the bracket I12 is fixed in the middle of the bracket II11. The worm I16 is connected to the output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com