A kind of thermosetting saturated carboxyl-terminated polyester resin and preparation method thereof

A carboxyl-terminated polyester and thermosetting technology, which is applied in the field of thermosetting saturated carboxyl-terminated polyester resin and its preparation, can solve the problems of unfavorable curing process of powder coating, low glass transition temperature, orange peel phenomenon in coating film and the like, Achieve the effect of solving stability and curing reaction activity, good crystallization performance, and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

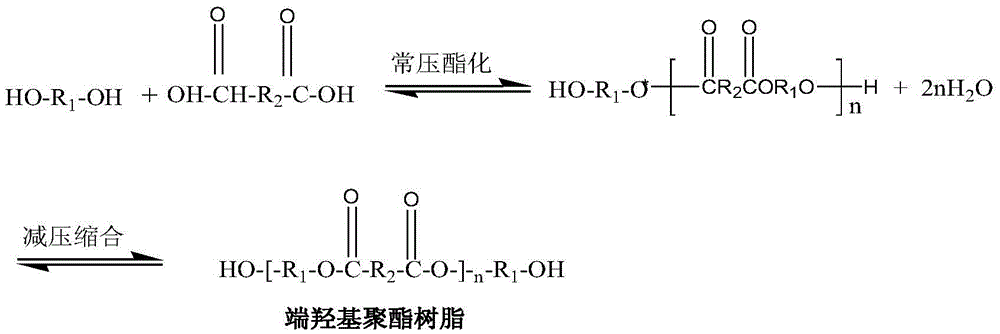

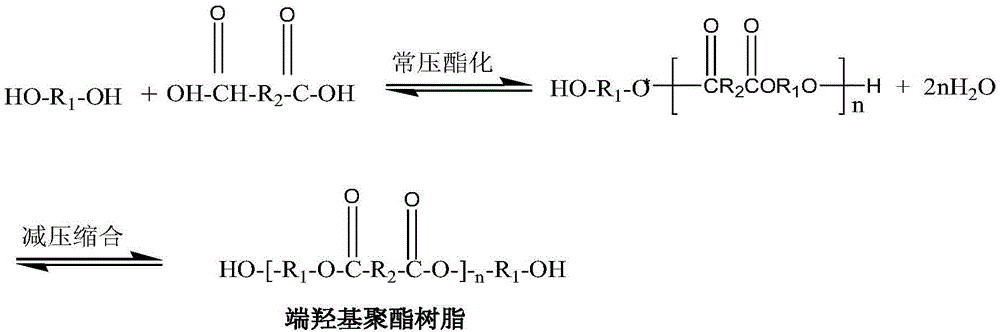

[0030] A method for preparing a thermosetting saturated carboxyl-terminated polyester resin, which uses diol monomers and dibasic acid monomers as raw materials and obtains them through direct esterification and a two-step synthesis process of esterification and carboxylation. The reaction principle is as follows :

[0031] The first step: polycondensation reaction, esterification and condensation into a polyester resin with a low degree of polymerization and a hydroxyl-terminated polyester resin,

[0032]

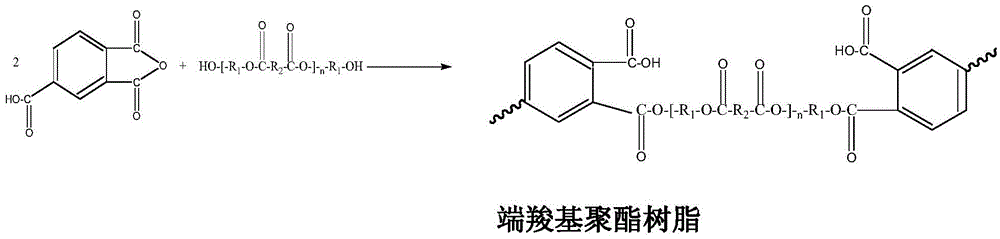

[0033] The second step: carboxylation, mainly by adding a dibasic acid to react with the above-condensed low-polymerization polyester resin to produce a carboxyl-terminated polyester resin,

[0034]

[0035] Wherein, R1: dibasic alcohol monomer structure, R2: dibasic acid monomer structure.

Embodiment 1

[0037] (1) Add 60 g of neopentyl glycol monomer and 0.3 g of catalyst n-butyl stannoic acid into the reaction vessel, after shaking and mixing, start to heat up and heat to about 130 ° C, keep warm, and observe that the neopentyl glycol monomer in the flask is completely After melting, add 80g of terephthalic acid monomer and stir evenly.

[0038] (2) Fill the reaction system with N 2 Gas, pump and charge three times, keep the system at N 2 In an air atmosphere, heat up to 230°C. Under this condition, diols and dibasic acid monomers undergo esterification and polycondensation reactions, and keep warm until the acid value of the reaction system is lower than 5mg KOH / g.

[0039] (3) Stop heating, control the temperature of the reaction system to drop to 170°C, then add 15g of adipic acid monomer to the reaction system according to the formula, and pay attention to maintaining the N of the system. 2 Then slowly heat up to 235°C, continue the polycondensation reaction, keep warm...

Embodiment 2

[0045] The present embodiment is basically the same as Example 1, and its difference is that in (1), the quality of the neopentyl glycol monomer is 50g, the catalyst n-butylstannoic acid is 0.4g, and the quality of the terephthalic acid monomer is 70g ; In (3), the additional adipic acid monomer is 15g; in (4), the added triphenyl phosphite is 0.4g; in (6), the added trimellitic anhydride 15g. According to the XRD powder diffraction test results, the crystallinity of the sample is 17.75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com