Rubber sheet cooling production device

A production device and rubber sheet technology, applied in the field of rubber production, can solve the problems of increased production cost, large amount of release agent used, and high price of release agent, and achieve the effects of increasing surface area, reducing production cost, and lowering water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

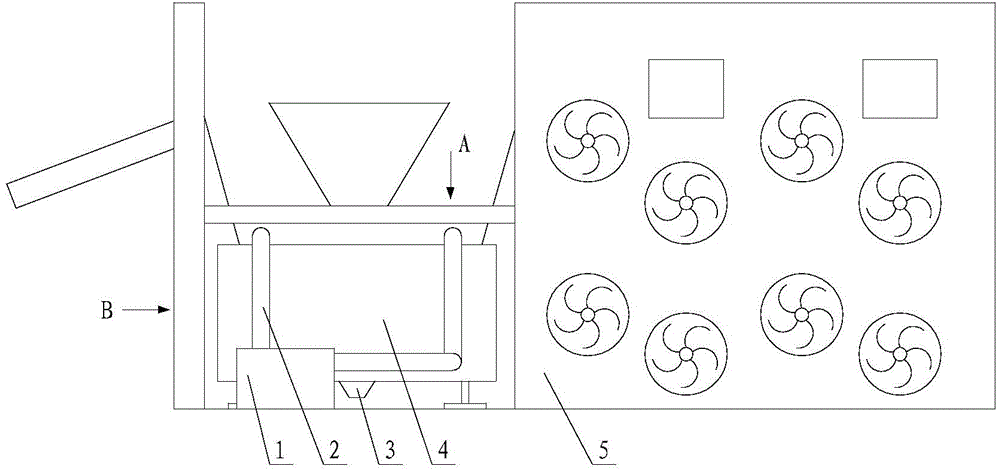

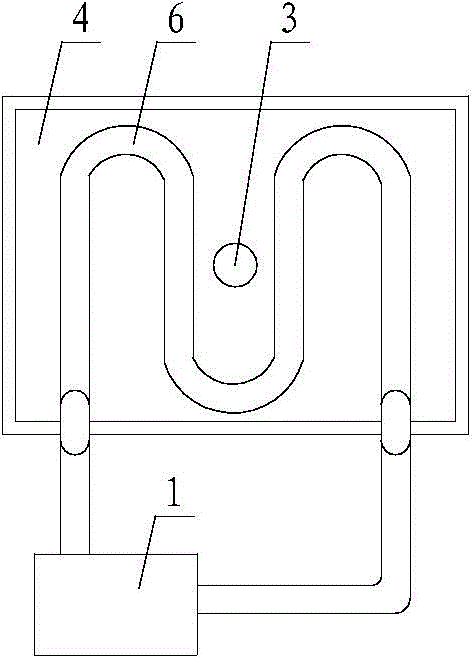

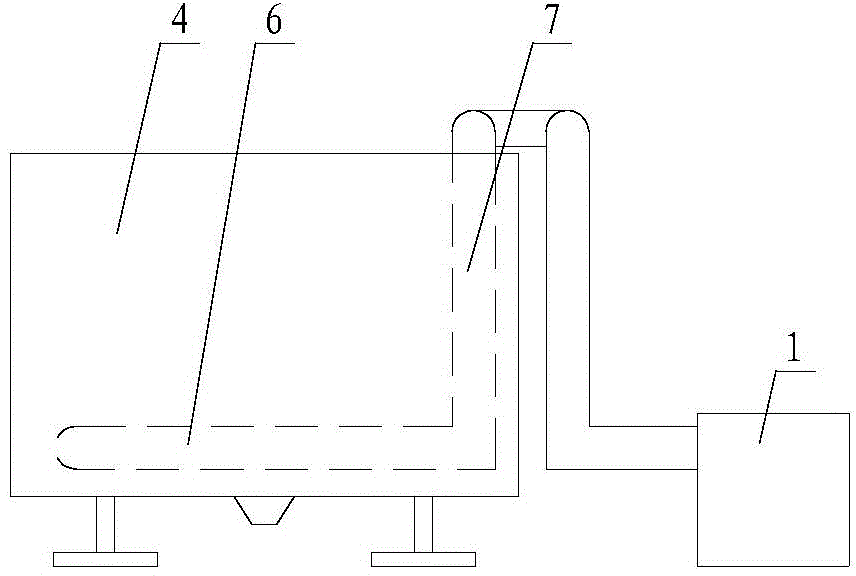

[0014] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0015] A rubber sheet cooling production device, including a water tank 4, which is arranged at the lower part behind the heating device in the rubber sheet production line 5, the bottom of the water tank is formed with a water outlet 3, and the water tank is filled with water and added with a spacer. Place a copper pipe 2 in this water tank, pass into cold water in this copper pipe. Both ends of the copper pipe extend to the outside of the water tank and are connected to an air conditioner compressor 1 to form a refrigeration circuit. The copper pipe located inside the water tank is composed of two vertical sections 7 and a horizontal section 6. The upper ends of the two vertical sections are respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com