Enamel reaction tank orifice protective reparation method

An enamel reaction and nozzle technology, which is applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve the corrosion of nozzles, the inability to protect enamel reaction tanks, and prolong the use of enamel reaction tanks Life and other issues, to achieve the effects of prolonging service life, economical maintenance, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

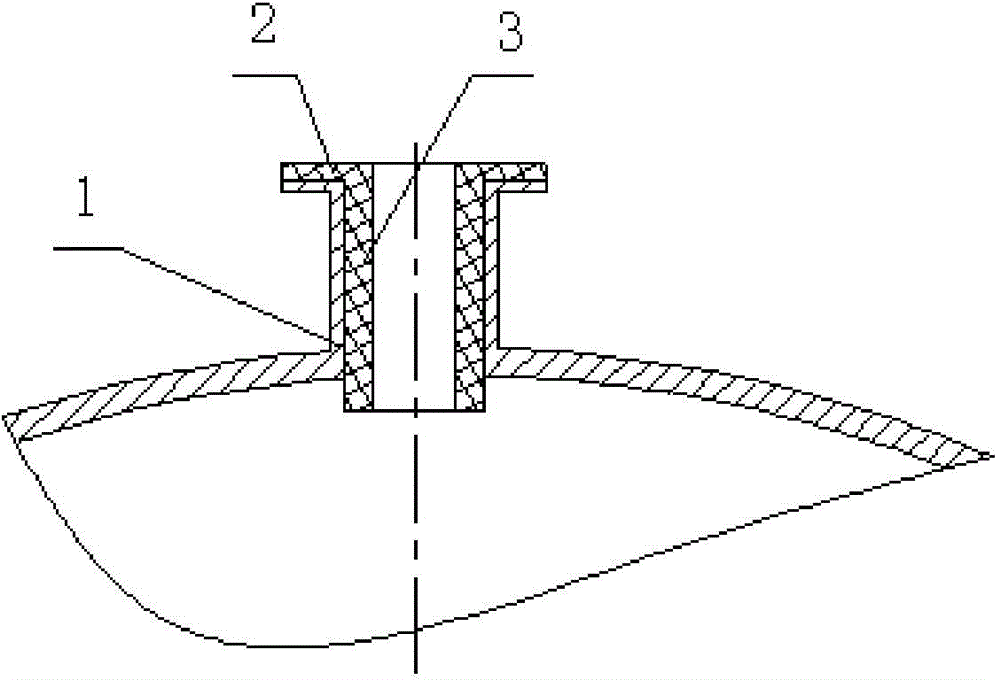

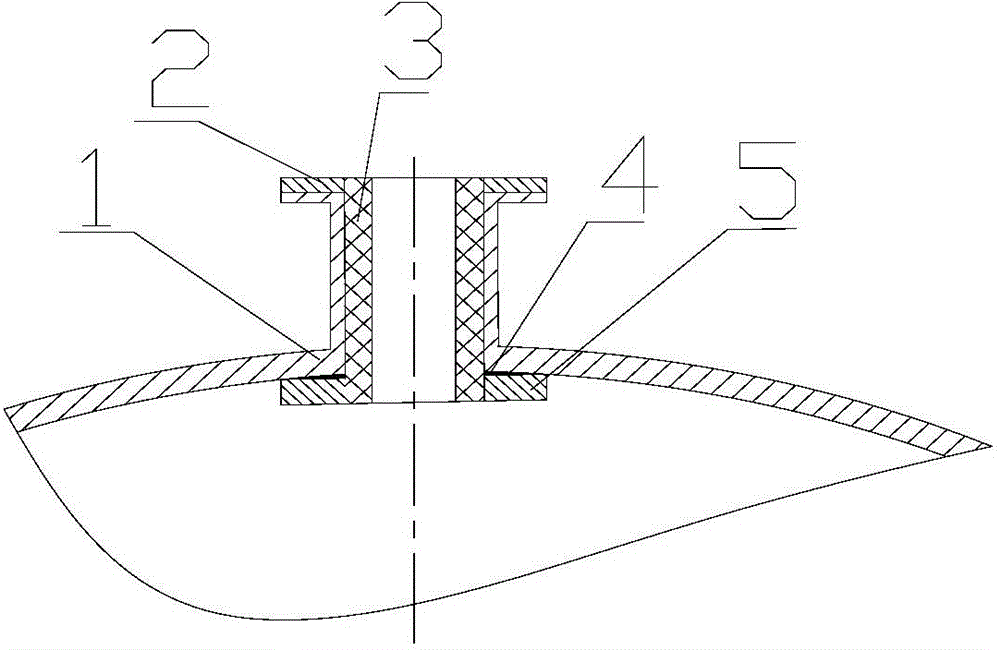

[0017] Such as figure 1 As shown, the mouth of the enamel reaction tank is prone to broken porcelain, which affects the product quality and the service life of the enamel reaction tank, and even causes the entire enamel reaction tank to be scrapped. The general protection of the existing enamel reaction tank nozzle is in the enamel The nozzle 1 of the reaction tank is inlaid with a polytetrafluoroethylene short-circuit 3 with a polytetrafluoroethylene flanging 2 to prevent corrosion of the enamel reaction tank and prolong the service life of the enamel reaction tank. The existing PTFE short-circuit with flanging is only a protective measure with a flanged short-connect at the mouth of the nozzle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com