Electrical arc extinguishing device

A technology of an arc extinguishing device and an air blowing device, which is applied in the electrical field, can solve problems such as adverse effects of switching components, achieve the effect of strengthening the cutting arc and increasing the arc extinguishing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

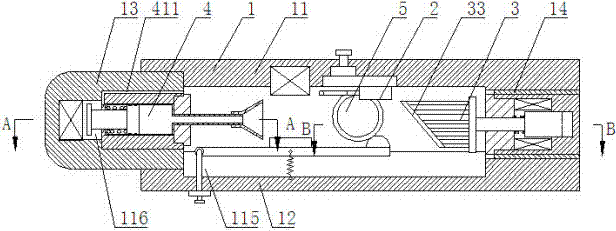

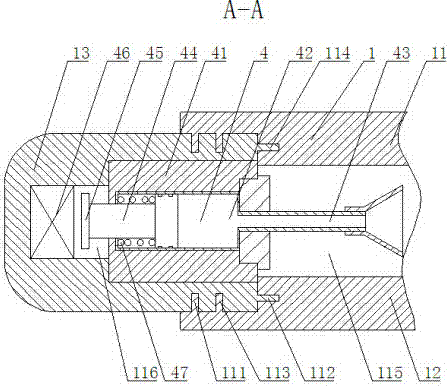

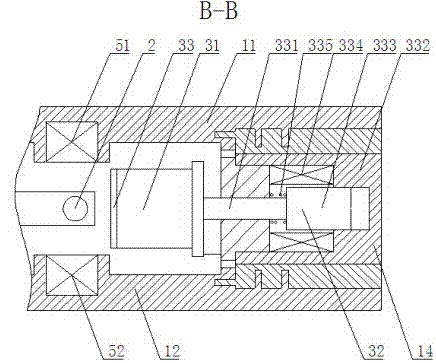

[0033] refer to Figure 1 to Figure 3 As shown, an electrical arc extinguishing device provided by the present invention includes a housing 1, a switch contact 2 arranged inside the housing 1, the contact includes a moving contact and a static contact, and also includes a The grid device 3, the air blowing device 4 for blowing the arc horizontally, the electromagnetic device 5 for creating a magnetic field between the moving contact and the static contact,

[0034] The grid device 3 is arranged opposite to the blowing device 4, the contact 2 is located between the grid device 3 and the blowing device 4, and the electromagnetic device is arranged on both sides of the contact 2,

[0035] The grid device 3 includes a plurality of groups of parallel metal grids 31 opposite to the contact 2, each metal grid 31 is connected with a driving device 32, and the driving device 32 drives the metal grid when the contact 2 is disconnected. The sheet 31 moves toward the middle of the contac...

Embodiment 2

[0045] refer to Figure 5 As shown, the main difference between this embodiment and Embodiment 1 is that the driving device 32 includes a slide bar 321, one end of the slide bar 321 is connected with each metal grating 31, and the other end of the slide bar 321 is provided with a The fourth electromagnet 322 in the sleeve 323 and the sliding rod 321 pass through the sliding sleeve 323 , the sliding sleeve 323 is connected with the housing 1 , and a first spring 324 is provided between the sliding sleeve 323 and the sliding rod 321 . It is also possible to use other driving devices 32 to drive the metal grid sheet 31 without affecting the implementation of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com