Device for depth maintenance of bottom-layer interfaces of western digital hard disk and bottom-layer communication method

A Western Digital hard drive, in-depth repair technology, which is applied in the deep repair of the underlying interface equipment and underlying communication fields of Western Digital hard drives, can solve problems such as complicated repair process, motor not rotating, and inability to read and write

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

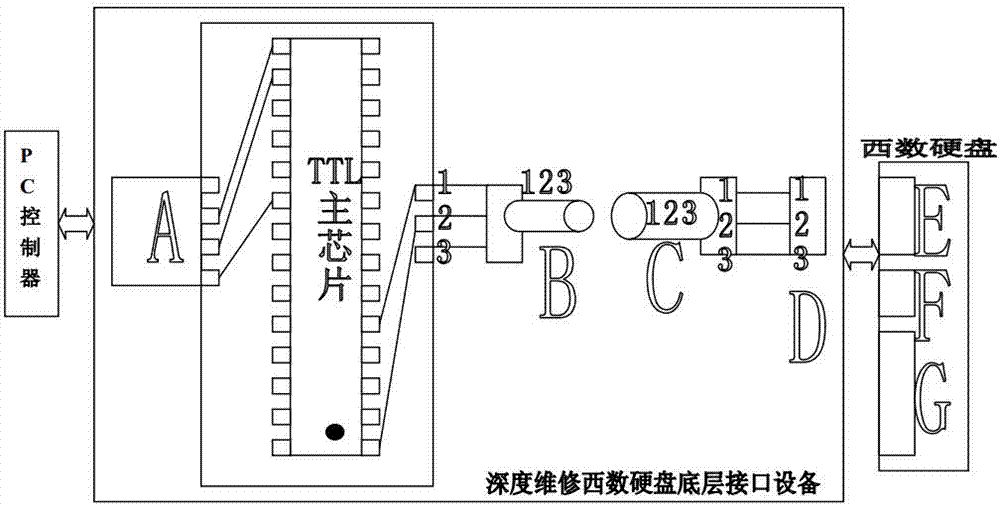

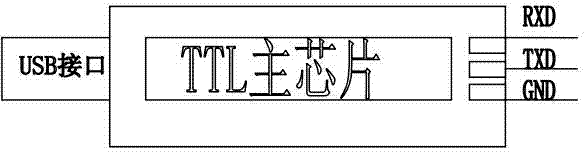

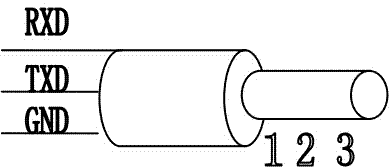

[0017] refer to figure 1 , a low-level interface device for in-depth maintenance of Western Digital hard drives, including a TTL main chip circuit board and a USB interface set on the circuit board, refer to figure 2 , and a pin jack similar to an audio cable, refer to image 3 . In addition, there are hole-type interfaces similar to audio extension cables and two rows of 8-core hole-type interfaces. The USB interface on the circuit board is used to connect the PC controller, and the two rows of 8-core hole-type interfaces are connected to the two Row of 8-pin pin sockets, refer to Figure 5 . The pin-type socket similar to the audio cable is connected to the hole-type interface similar to the audio extension cable, refer to Figure 4 . Viewed from the front, the TTL main chip is connected to the RXD end and TXD end of the two rows of 8-pin hole interfaces through the tenth and fourteenth pins on the right side respectively, and the two rows of 8-pin hole interfaces are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com