Method for determining content of phosphorus in ferroniobium

A determination method and technology for phosphorus content are applied in the field of chemical analysis of niobium-containing ferroalloys, which can solve the problems of cumbersome operation of the method and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

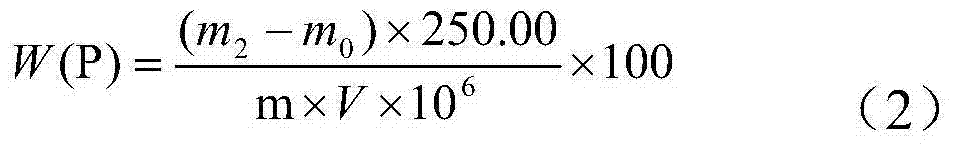

Image

Examples

Embodiment Construction

[0009] Hereinafter, the method for determining the phosphorus content in ferroniobium of the present invention will be described in detail in combination with exemplary embodiments.

[0010] In the present invention, preferably, the ferroniobium to be tested contains not more than 0.5% phosphorus by mass percentage.

[0011] In an exemplary embodiment of the present invention, the assay method of phosphorus content in ferro-niobium comprises the following steps of carrying out in order:

[0012] Anhydrous sodium carbonate, sodium peroxide and ferroniobium are mixed, heated to obtain a melt, that is, an alkali melt of ferroniobium, and then cooled. For example, before weighing the sample, add a small amount of anhydrous sodium carbonate first, the purpose is to allow the sample to fully mix with sodium peroxide when mixing after adding sodium peroxide, and add some peroxide before weighing the sample. Sodium, do not add anhydrous sodium carbonate, but when weighing the sample,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com