Visual observing system for growth process of microcrystalline silicon film and measurement method

A microcrystalline silicon thin film and observation system technology, applied in the field of optical measurement, can solve the problems of low resolution, single observation sample, and inability to adapt to microcrystalline silicon thin film observation, etc., achieve high resolution, improve efficiency and precision, and realize continuous The effect of dynamic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

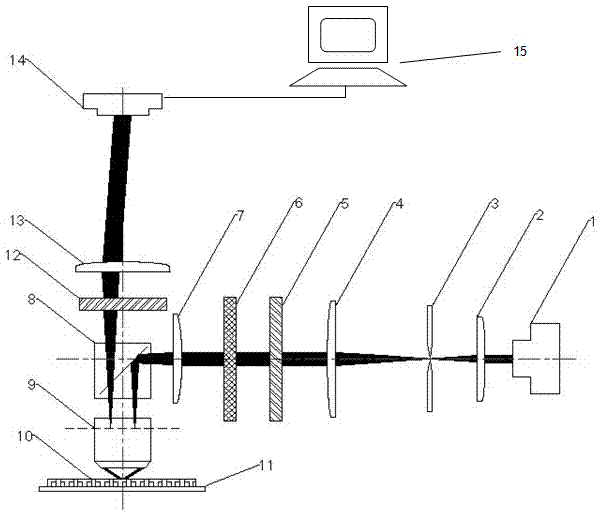

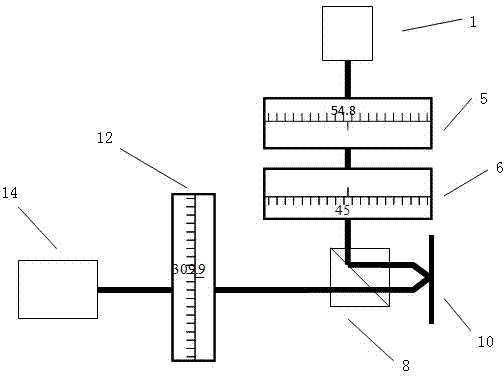

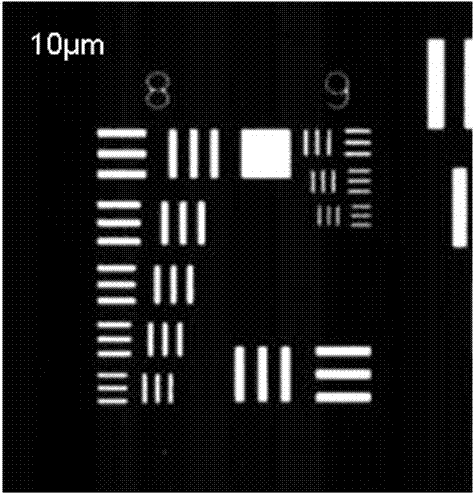

[0028] Such as figure 1As shown, the present invention provides a visual observation system for the growth process of a microcrystalline silicon film, including a light source 1, a pinhole 3, a polarizer 5, a 1 / 4 wave plate 6, a converging lens, a dichroic prism 8, and a vertical objective lens 9 , sample 10, stage 11, analyzer 12, CCD camera 14, computer 15. Among them, the illumination source 1 adopts a monochromatic high-power parallel light source with a wavelength of 460 nm and an output power of 46 μw. The pinhole diameter is 100 μm. The converging lenses are all convex lenses, specifically including a first converging lens 2, a second converging lens 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com