A prestressing device for shed-type support

A technology of application device and shed-type support, which is applied in the direction of mine roof support, mining equipment, earthwork drilling and mining, etc., to achieve the effect of reducing labor intensity of workers, high support strength and realizing close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

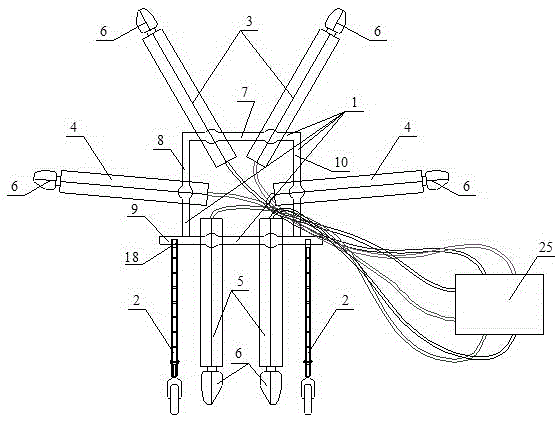

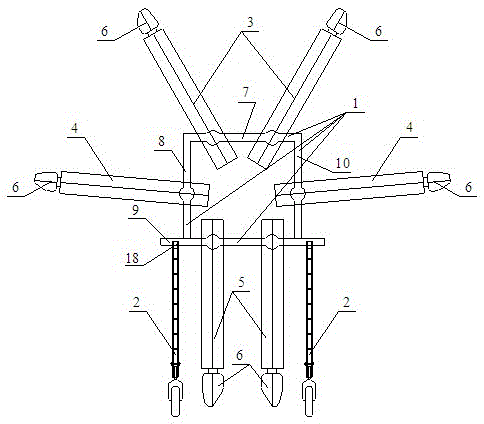

[0026] like figure 1 As shown, the shed-type support prestressing device of the present invention includes two parts: a basic frame structure and an integrated hydraulic oil pump 25 .

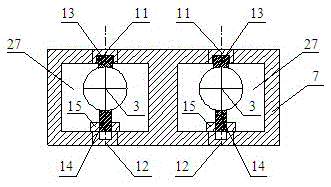

[0027] like figure 2 As shown, the basic frame structure includes an upper frame structure 1 and a lower leg support structure 2 . The upper frame structure 1 in the basic frame structure specifically includes a top steel frame 7 at the top of the structure, a bottom steel frame 9 at the bottom of the structure, left steel frames 8, and right steel frames 10 on both sides. The surface steel frame, the bottom steel frame, the left steel frame and the right steel frame are sequentially welded into a rectangular frame structure, the top steel frame 7 is connected to two top multi-stage hydraulic cylinders 3, and the left steel frame 8 1. The steel frames 10 on the right side are respectively connected to a side multi-stage hydraulic cylinder 4 , and the bottom steel frame 9 is connected to two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com