A folding telescopic roadway hydraulic support

A hydraulic support and telescopic technology, applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems that the roadheader cannot work in parallel, the support cannot keep up with the head, and the roof is easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

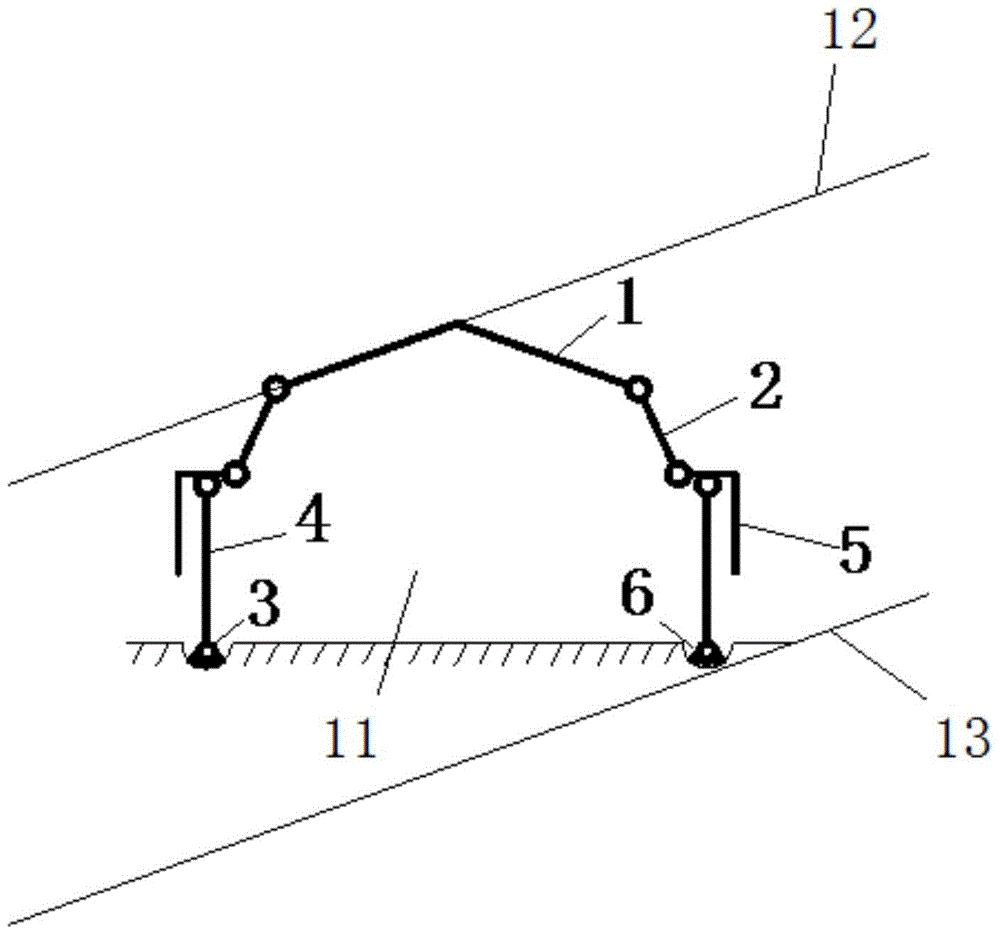

[0044] The shape of the present invention in the supporting state is consistent with the cross section of the roadway 11, while supporting the roof 12 of the roadway, the active support of the two sides is realized. Withdraw the handling device to fold and shrink the working support vertically to the direction of the roadway, and keep this state in the support area supported by the working support along the direction of the roadway 11 to move to the front and then erect, so as to realize the recycling of the front support and the rear return.

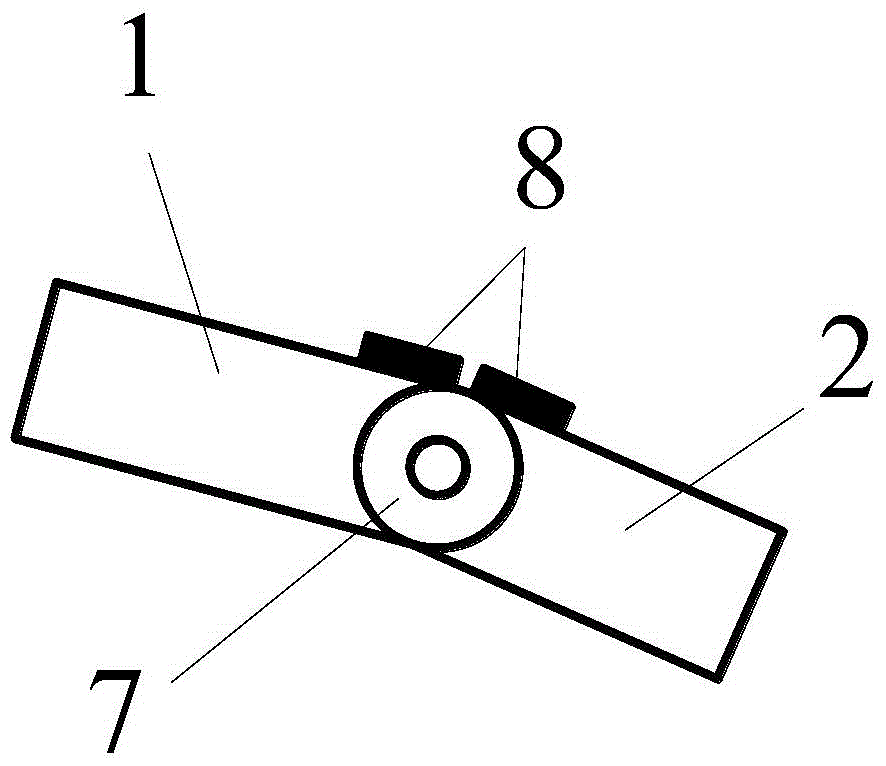

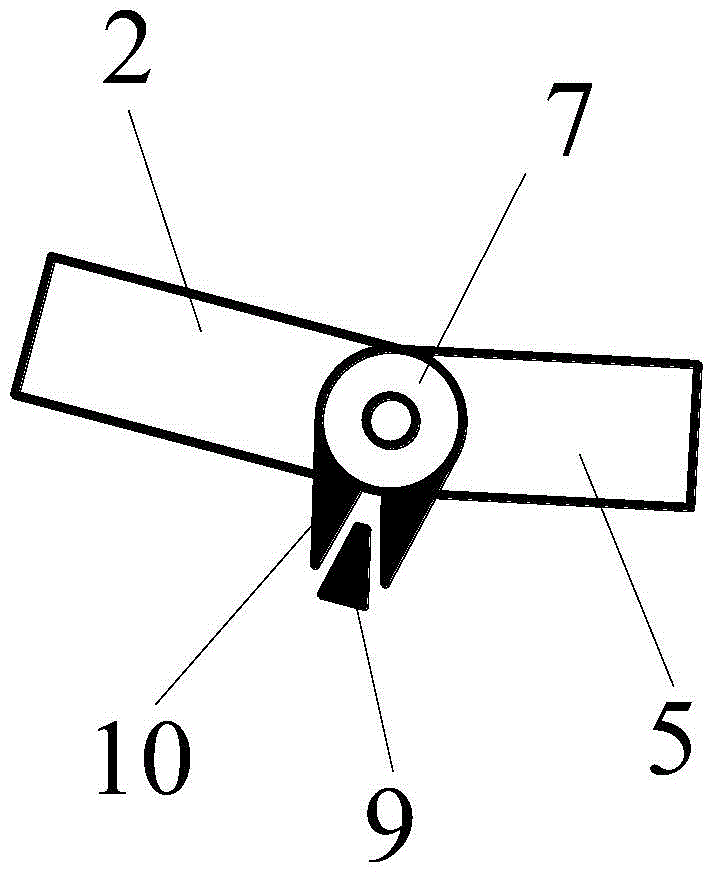

[0045]The present invention comprises a top beam 1, two corner beams 2, two side guards 5, two side supports 4 and a base 3, the top beam 1 and the corner beams 2, the corner beams 2 and the side guards 5, and the side guards The connection between 5 and the column is a hinge joint, the connection between the side support 4 and the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com