A kind of sealing filler injectable oil well polished rod sealer

A technology of polished rod sealer and sealing packing, which is applied in the directions of sealing/packing, wellbore/well parts, earthwork drilling and production, etc., which can solve problems such as reducing production time rate, affecting production, and adverse effects on normal production, so as to improve production The effect of time rate, increased output, reduced material consumption and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

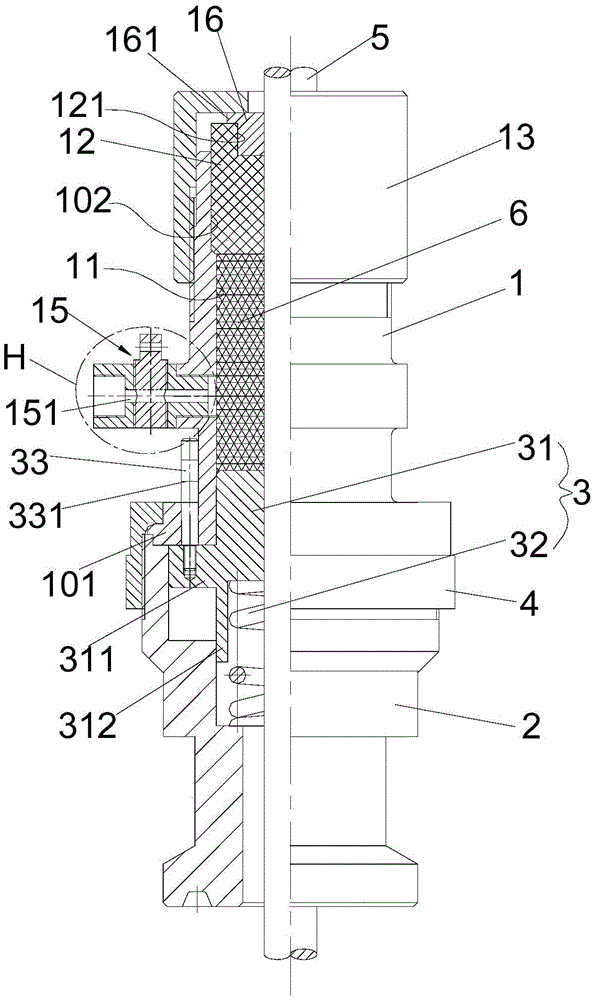

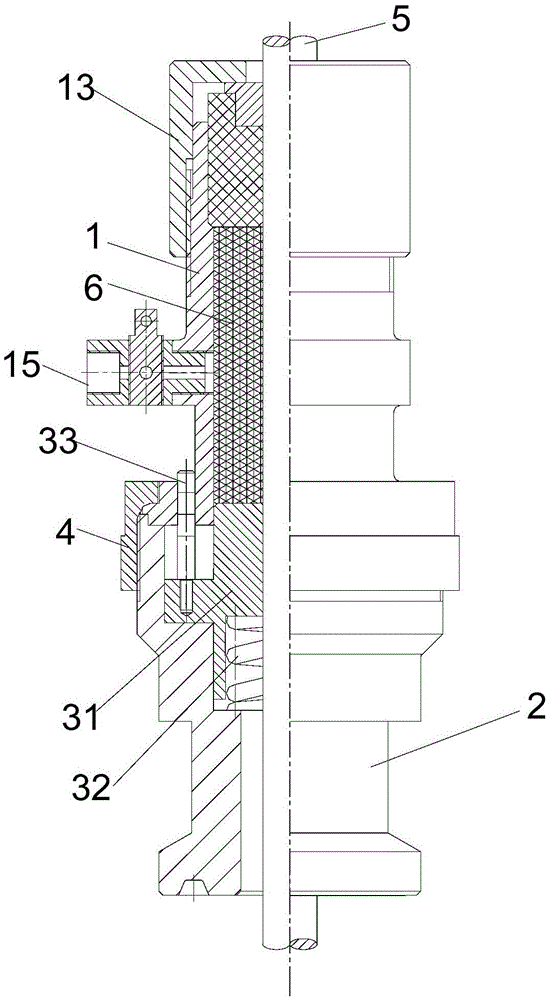

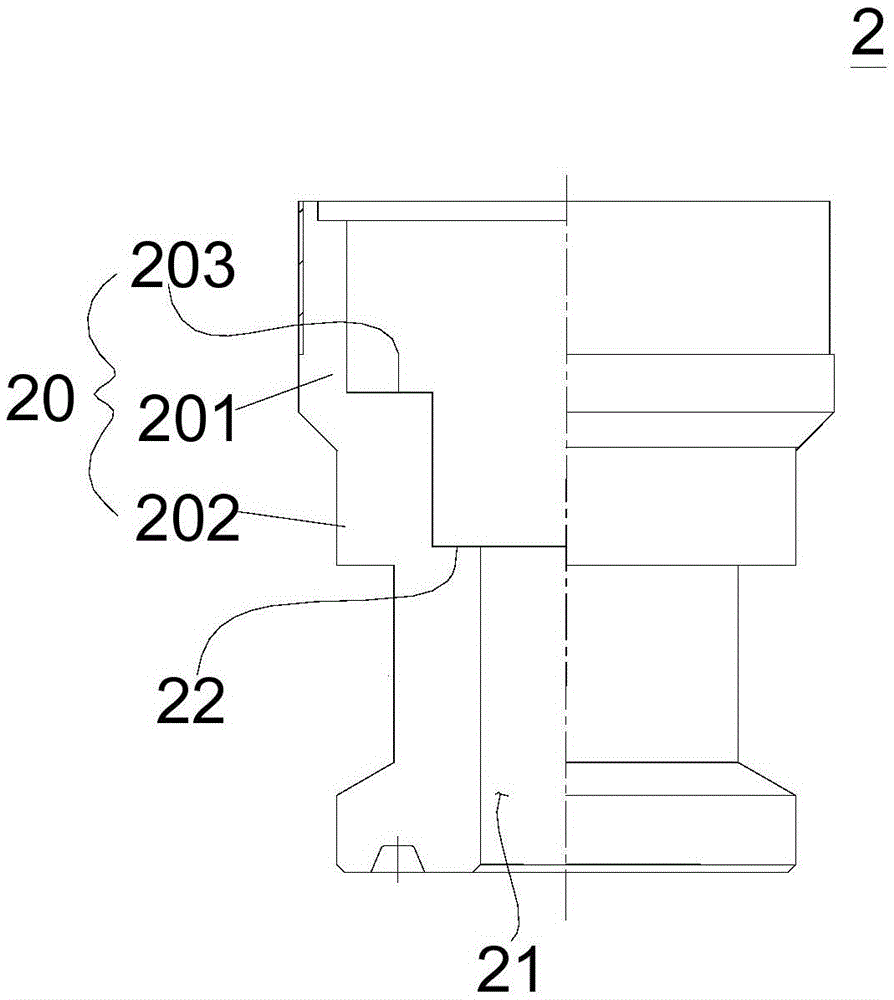

[0043]The present invention provides a sealing filler injectable type oil well polished rod sealer, which includes a box body, a box seat and an elastic compensating ring, the box body is placed on the box seat, and the two are connected by a The box body is formed with a through cavity in the axial direction, and a retaining ring is embedded at the upper port, and the retaining ring is fixed on the box body through an upper pressure cap. The upper end of the compensation ring is movably embedded in the lower port of the box body, and is closely attached to the inner surface of the box body. Its inner diameter is the same as that of the retaining ring. The elastic compensation ring part The lower end of the lower end is accommodated in the ring portion of the upper end of the box seat, and the box seat is further provided with a through hole coaxially arranged with the ring portion along the vertical direction, and the through hole is adjacent to the ring portion The lower sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com