Serrated steel-concrete shear connector

A shear connector and concrete technology, which is applied in the direction of construction and building structure, can solve the problems of low economy and high price of shear connectors, save the processing and construction process, convenient construction, and connection transmission. Reliable and effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

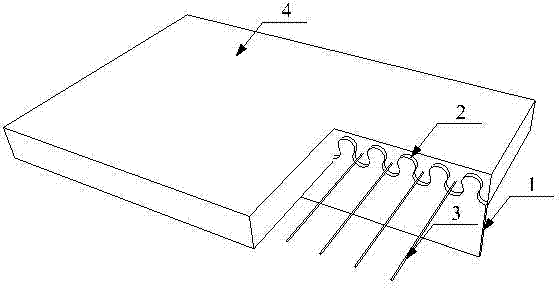

[0028] figure 1 Shown:

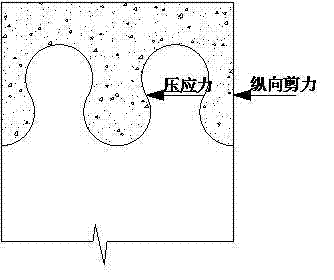

[0029] It includes a steel web 1, and a streamlined zigzag shear connector 2 is cut from the top of the steel web by a CNC machine tool. The cutting of the steel web can be completed in a factory, which is simple and convenient.

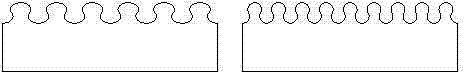

[0030] Including the zigzag shear connector 2, the zigzag shear connector 2 is located on the steel web 1, and its basic shape is figure 2 Streamlined as shown, the shape can also be stretched lengthwise. At the same time, the basic shape of the zigzag shear connector 2 is a centrally symmetrical figure, that is, two identical steel webs 1 with the zigzag shear connector 2 can be obtained in one cut.

[0031] Including the shear reinforcement 3, the shear reinforcement 3 is arranged between the zigzag shear connectors 2, and one or more shear reinforcements can be arranged at each interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com