Wood floor chase mortise machining device

A technology for groove and tenon processing and wood flooring, which is applied in the field of wood processing, can solve the problems of low processing efficiency, poor controllability and low processing efficiency of wood floor groove and tenon, so as to improve the controllability of equipment, the breadth of use, and the variety of types. The effect of diversity and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

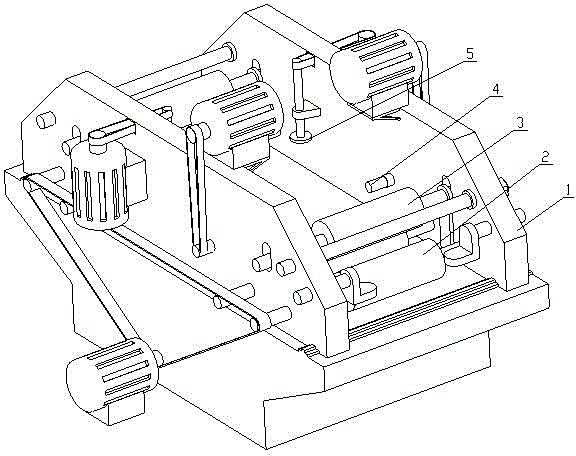

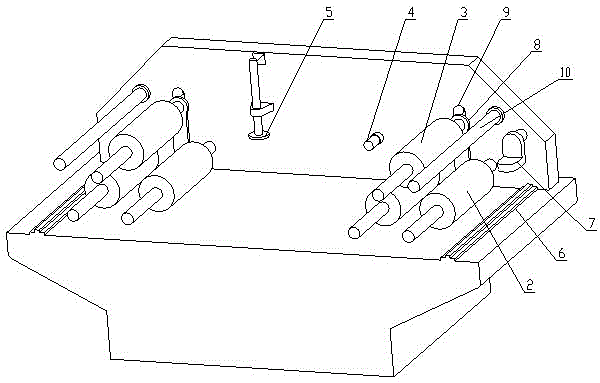

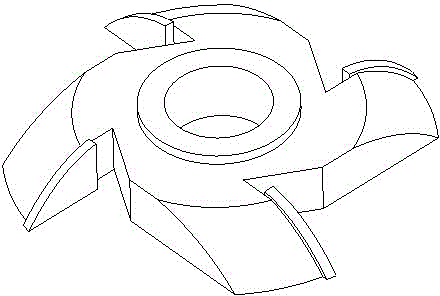

[0020] Embodiment 1 of the present invention: a wooden floor groove and tenon processing device, such as Figure 1-4 As shown, it includes a machine body 1, a conveying roller 2, a pressure roller 3, a first cutter 4 and a second cutter 5, the conveying roller 2 is arranged at the lower part of the body 1, the pressure roller 3 is arranged at the upper part of the body 1 and is located above the conveying roller 2, the second A cutter 4 is arranged in the middle of the body 1 and is located between the horizontal position of the conveying roller 2 and the pressure roller 3. The center line of the first cutter 4 is aligned with the middle position of the conveying roller 2 and the pressure roller 3, so that the wooden floor being conveyed is aligned with the first roller. The center of one cutter 4 is horizontal, and the processing is even. The second cutter 5 is arranged in the middle of the machine body 1 and its center is at the same horizontal position as the center of the f...

Embodiment 2

[0026] Embodiment 2 of the present invention: a wooden floor groove and tenon processing device, including a body 1, a conveying roller 2, a pressure roller 3, a first cutter 4 and a second cutter 5, the conveying roller 2 is arranged at the lower part of the body 1, and the pressure roller 3 It is arranged on the upper part of the machine body 1 and above the conveying roller 2. The first cutter 4 is arranged in the middle of the machine body 1 and between the horizontal positions of the conveying roller 2 and the pressure roller 3. The centerline of the first cutter 4 is in line with the conveying roller 2 and the pressure roller 3 Align the middle position, make the wooden floor delivered and the center level of the first cutter 4, process evenly, the second cutter 5 is arranged in the middle part of the body 1 and its center is in the same horizontal position as the first cutter 4 center.

[0027] Wherein, the first cutter 4 and the second cutter 5 are both symmetrically ar...

Embodiment 3

[0031] Embodiment 3 of the present invention: a wooden floor groove and tenon processing device, including a body 1, a conveying roller 2, a pressure roller 3, a first cutter 4 and a second cutter 5, the conveying roller 2 is arranged at the lower part of the body 1, and the pressure roller 3 It is arranged on the upper part of the machine body 1 and above the conveying roller 2. The first cutter 4 is arranged in the middle of the machine body 1 and between the horizontal positions of the conveying roller 2 and the pressure roller 3. The centerline of the first cutter 4 is in line with the conveying roller 2 and the pressure roller 3 Align the middle position, make the wooden floor delivered and the center level of the first cutter 4, process evenly, the second cutter 5 is arranged in the middle part of the body 1 and its center is in the same horizontal position as the first cutter 4 center.

[0032] Wherein, the first cutter 4 and the second cutter 5 are both symmetrically ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com