A fabric flame retardant coating coating process

一种阻燃涂层、涂布工艺的技术,应用在涂层、对表面涂布液体的装置、纺织品和造纸等方向,能够解决阻燃防水性能不再提高、阻燃防水性能达不到等问题,达到解决阻燃防水性能上限的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

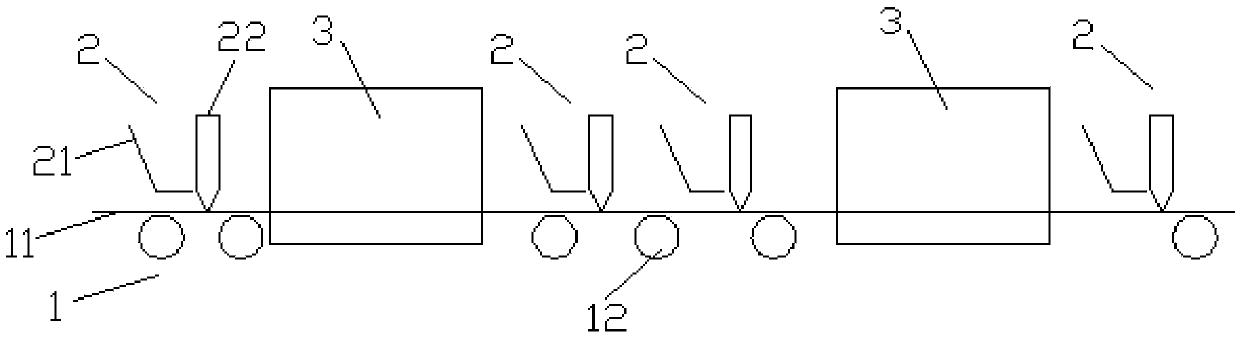

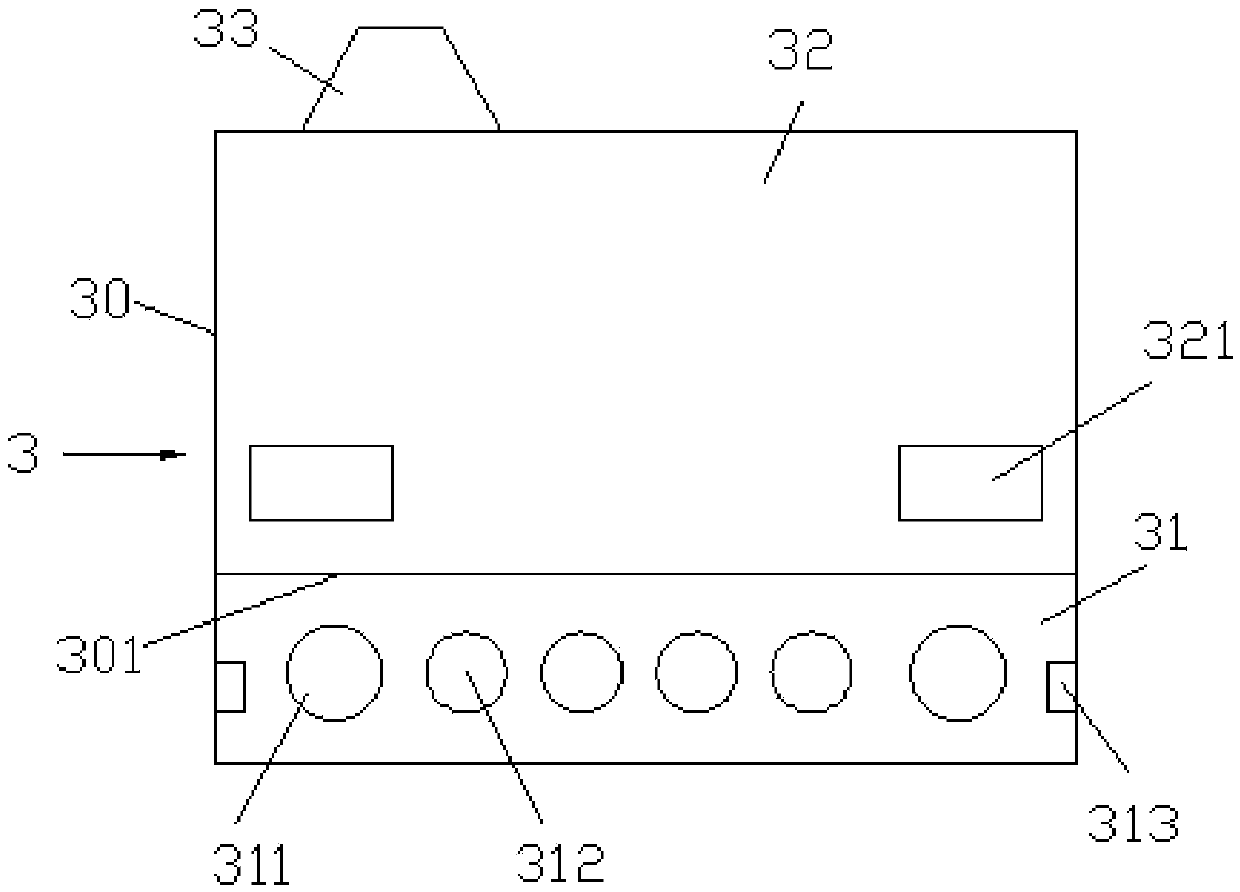

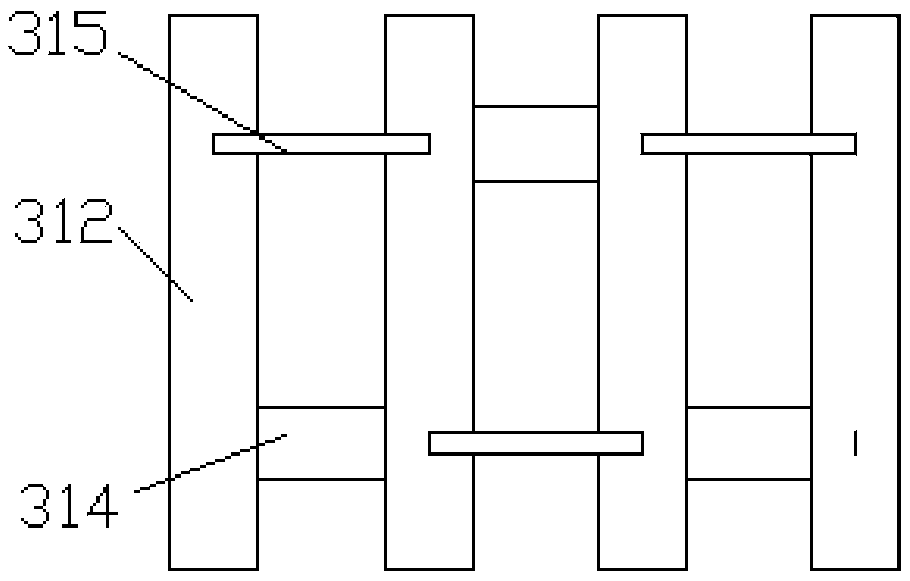

[0019] Combine the following Figure 1 to Figure 6 Examples of the present invention will be described in detail.

[0020] Such as Figure 1 to Figure 5 The shown fabric flame retardant coating coating equipment includes a fabric conveying device 1 for conveying fabrics, an unwinding device 4 and a tensioning device 5 are sequentially arranged on the front side of the fabric conveying device, and an unwinding device 5 is sequentially arranged on the rear side of the fabric conveying device A cooling device 7 and a winding device 8 are provided, and a coating coating device for flame retardant coating coating is provided in the fabric conveying direction of the fabric conveying device. The fabric conveying device 1 includes several conveying rollers 12 arranged along the fabric conveying direction, and the fabric 11 is conveyed by the conveying rollers 12 .

[0021] After the fabric 12 is released from the unwinding device 4, the tension is controlled by the tensioning device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com