Automatic thread feeding system of sewing machine and control method thereof

A sewing machine and sewing thread technology, applied in the field of sewing machines, can solve problems such as affecting stitches, affecting the flatness of fabrics, and disordered stitches, and achieve the effects of accurate timing and thread quantity, quality assurance, and neat stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

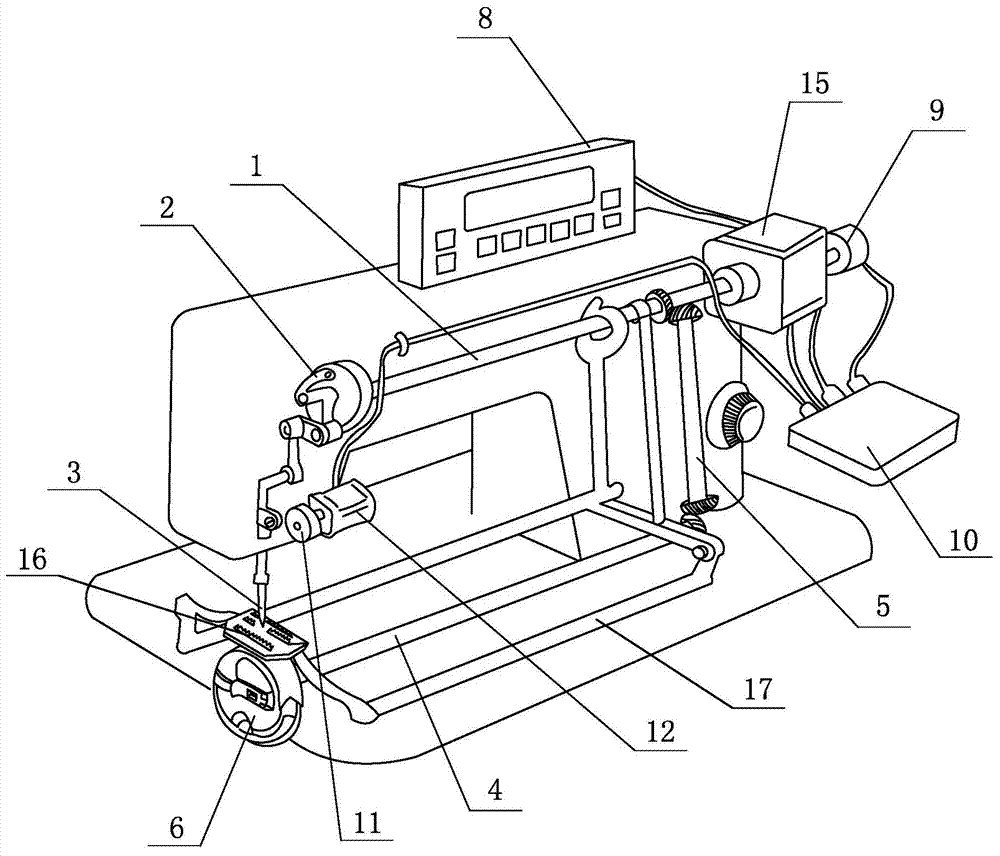

[0045] Embodiment one: see Figure 1-8 As shown, an automatic thread feeding system for a sewing machine includes:

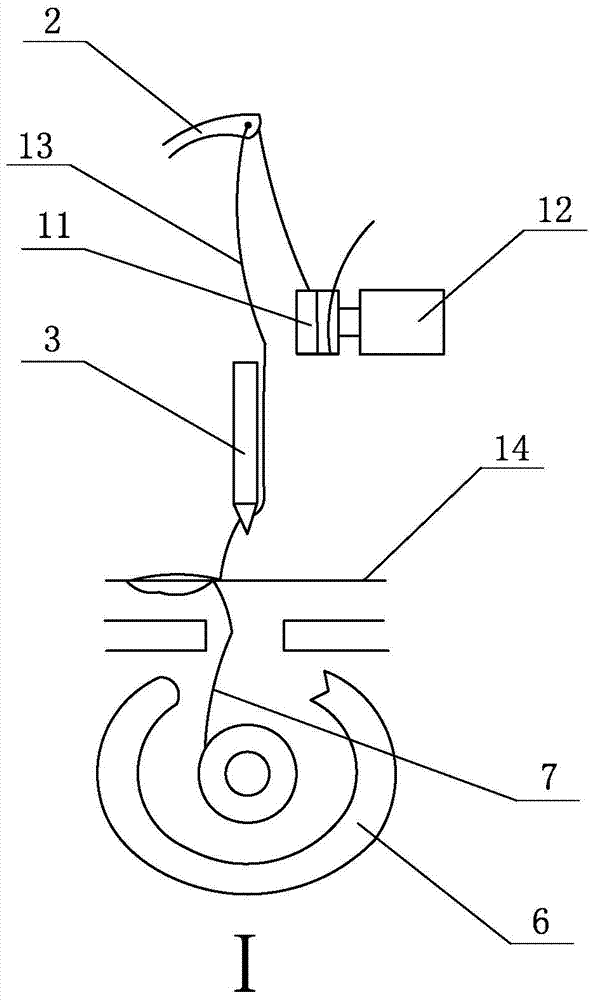

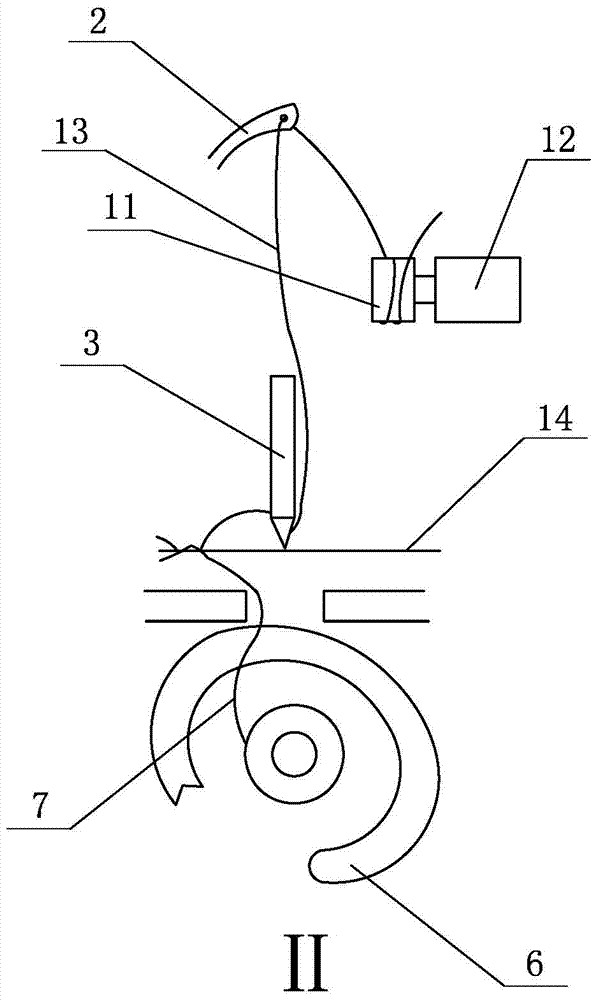

[0046] Upper shaft 1, one end of the upper shaft 1 is connected to the sewing machine driving mechanism 15, and the other end is connected to the thread take-up lever 2 and the sewing needle 3, and the sewing machine driving mechanism 15 is a driving motor;

[0047] The lower shaft 4, one end of the lower shaft 4 is connected to the upper shaft 1 through the transmission shaft 5, and the other end is provided with a rotary hook 6, and the sewing bottom thread 7 is wound on the rotary hook 6;

[0048] A control device, the control device includes an operation panel 8, an encoder 9 and a control chip 10, and the signal output ends of the operation panel 8 and the encoder 9 are connected to the control chip 10;

[0049]The cloth feeding device, the cloth feeding device is a feeding rake 16, and the feeding rake 16 is connected with the upper shaft through a connec...

Embodiment 2

[0067] Embodiment 2: An automatic thread feeding system for a sewing machine. In this embodiment, its structure is basically similar to that of Embodiment 1. The difference is that the sewing machine also includes a feed motor, and the output shaft of the feed motor is A rotating shaft is connected, the cloth feeding device is connected with the feeding motor through the rotating shaft, and the signal output end of the feeding motor is connected with the control device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com