A kind of disperse dye composition, disperse dye and its preparation method and application

A technology of disperse dyes and compositions, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of high cost, dyeing condition dependence, and level dyeing property not as good as C.I. Disperse Orange 76, and achieve good perspiration fastness , Good dry rubbing fastness, high strength, economical and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

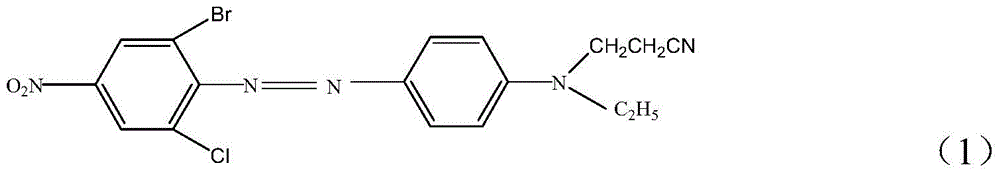

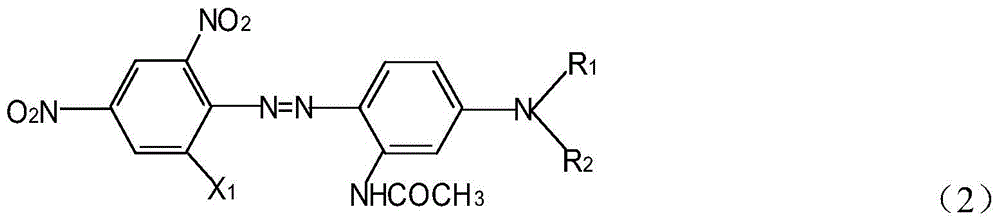

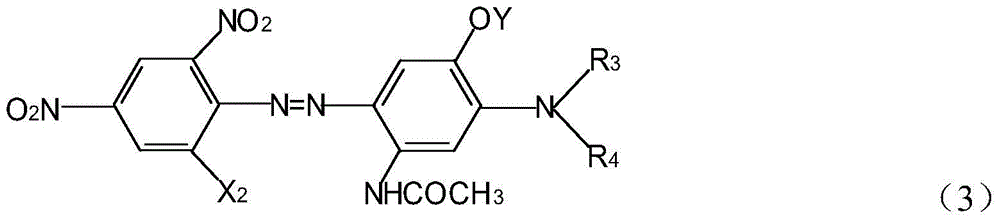

Embodiment 1

[0044] With 55 grams of formula (1) dye components, 20 grams of formula (2-2) dye components, 25 grams of formula (3-3) dye components, 50 grams of dispersant MF and 50 grams of lignin 85A, add 300 grams of water Stir well, grind, disperse and dry to obtain disperse dyes, and suede fabrics with excellent fastness properties can be obtained by dyeing suede fabrics.

Embodiment 2

[0055] With 18 grams of formula (1) dye components, 36 grams of formula (2-1) dye components, 46 grams of formula (3-1) dye components, 80 grams of dispersant CNF and 20 grams of lignin 83A, add 350 grams of water Stir well, grind, disperse and dry to obtain finished dyestuffs, and suede fabrics with excellent fastness properties can be obtained by dyeing suede fabrics.

Embodiment 3-10

[0065] According to the formula in Table 3, add an appropriate amount of additives and water, stir, grind, and dry to make a disperse dye. Wherein the moisture weight in Table 3 is the moisture weight of final disperse dye finished product.

[0066] table 3

[0067]

[0068] The dry rubbing fastness, perspiration fastness and strength of the finished dyes prepared in Examples 3-10 were measured by the method of Examples 1 and 2, and the results are shown in Table 4.

[0069] Table 4

[0070] name Dry rubbing fastness Perspiration fastness strength% Example 3 4 4-5 101.0 Example 4 5 5 109.8 Example 5 4-5 4-5 101.8 Example 6 5 5 109.1 Example 7 5 4-5 108.1 Example 8 5 4-5 109.1 Example 9 4-5 4-5 102.1 Example 10 4-5 4-5 103.0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com