Scraper conveyer and fully-mechanized coal mining device

A technology of scraper conveyor and scraper, which is applied in the field of scraper conveyor and fully mechanized mining equipment, and can solve left-right deflection (horizontal deflection) or up-and-down deflection (vertical deflection, shearer traction gear tooth meshing) Avoid problems such as wear and large changes in the meshing pitch of the pin teeth, so as to achieve the effects of not easily causing failures, smooth traction and cutting, and reducing meshing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

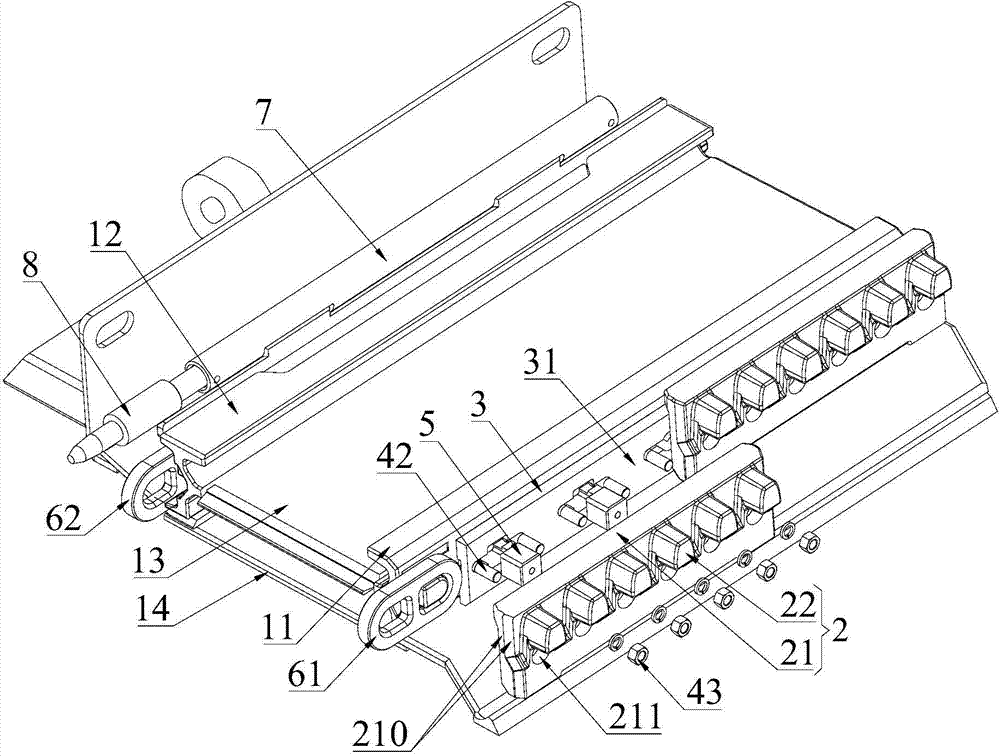

[0030] see figure 1 , shows the top view structure of the middle trough 1 with two adjacent sections in the scraper conveyor provided by the embodiment of the present invention. Those skilled in the art can understand that when working in the roadway, the scraper conveyor usually includes multiple sections sequentially The connected middle groove 1 provides a longer walking track for the shearer.

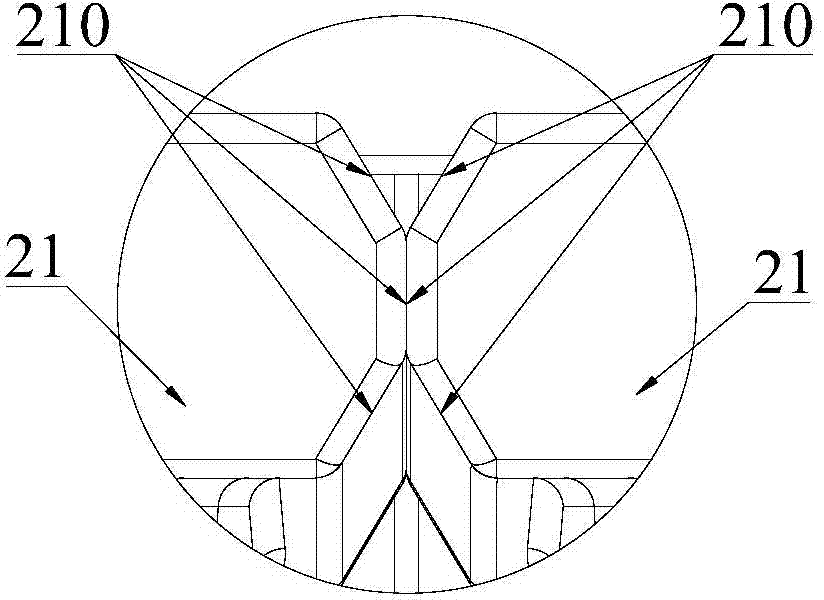

[0031] combined reference Figure 3 to Figure 7 Each middle groove 1 includes a baffle groove side 12, a middle plate 13, a bottom plate 14 and a blade groove side 11, and the middle plate 13 and the bottom plate 14 are respectively connected between the baffle groove side 12 and the blade groove s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com