Aircraft main landing gear hatch door assembling coordinate platform

A technology for landing gear hatches and landing gears, which is applied in aircraft assembly, aircraft parts, ground installations, etc., and can solve the problem of large shape differences between hatches, uneven gaps between hatches, and huge cost, etc. problems, to achieve the effect of ensuring functionality and reliability requirements, reducing production costs and assembly risks, and reducing installation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

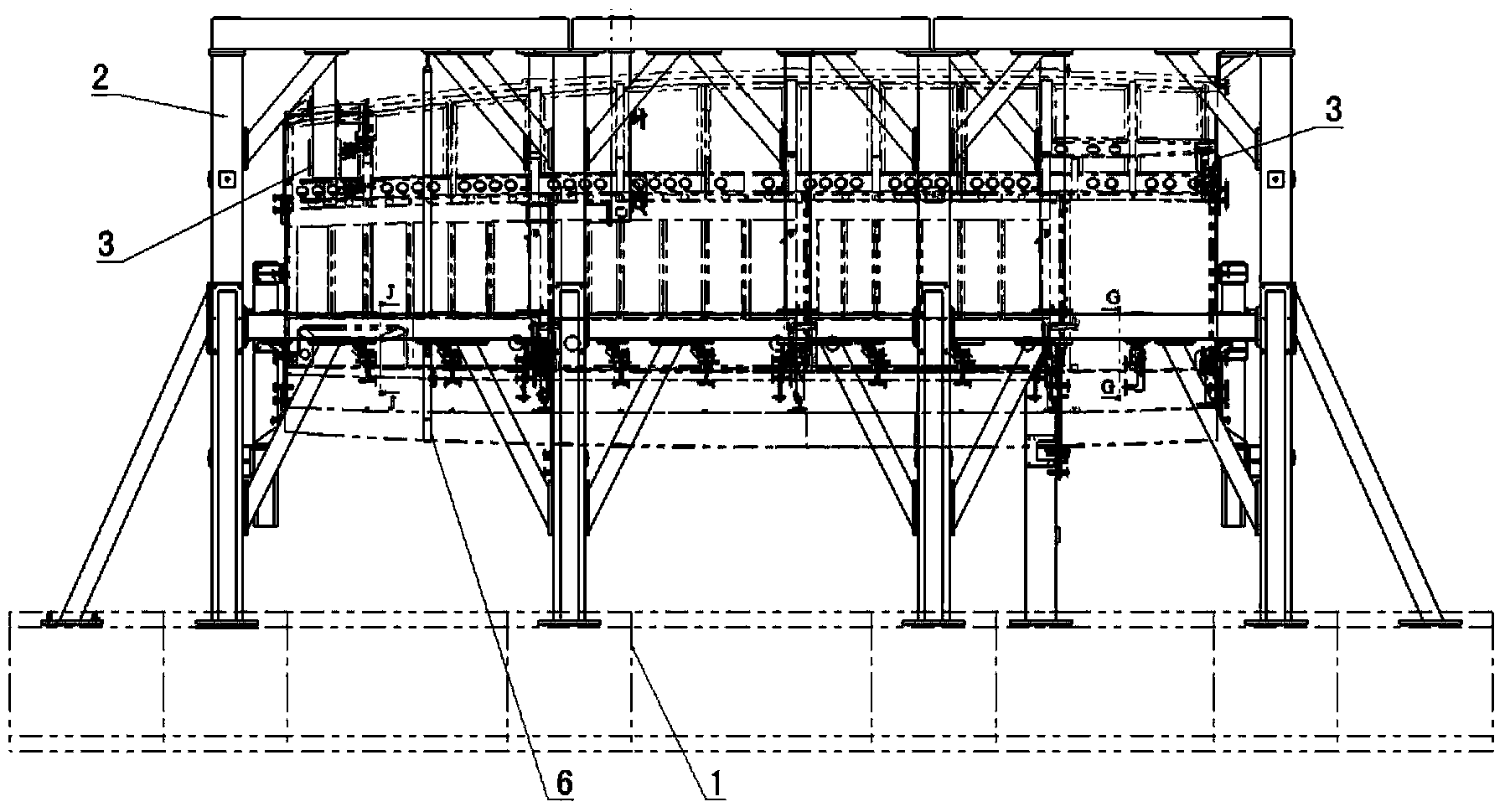

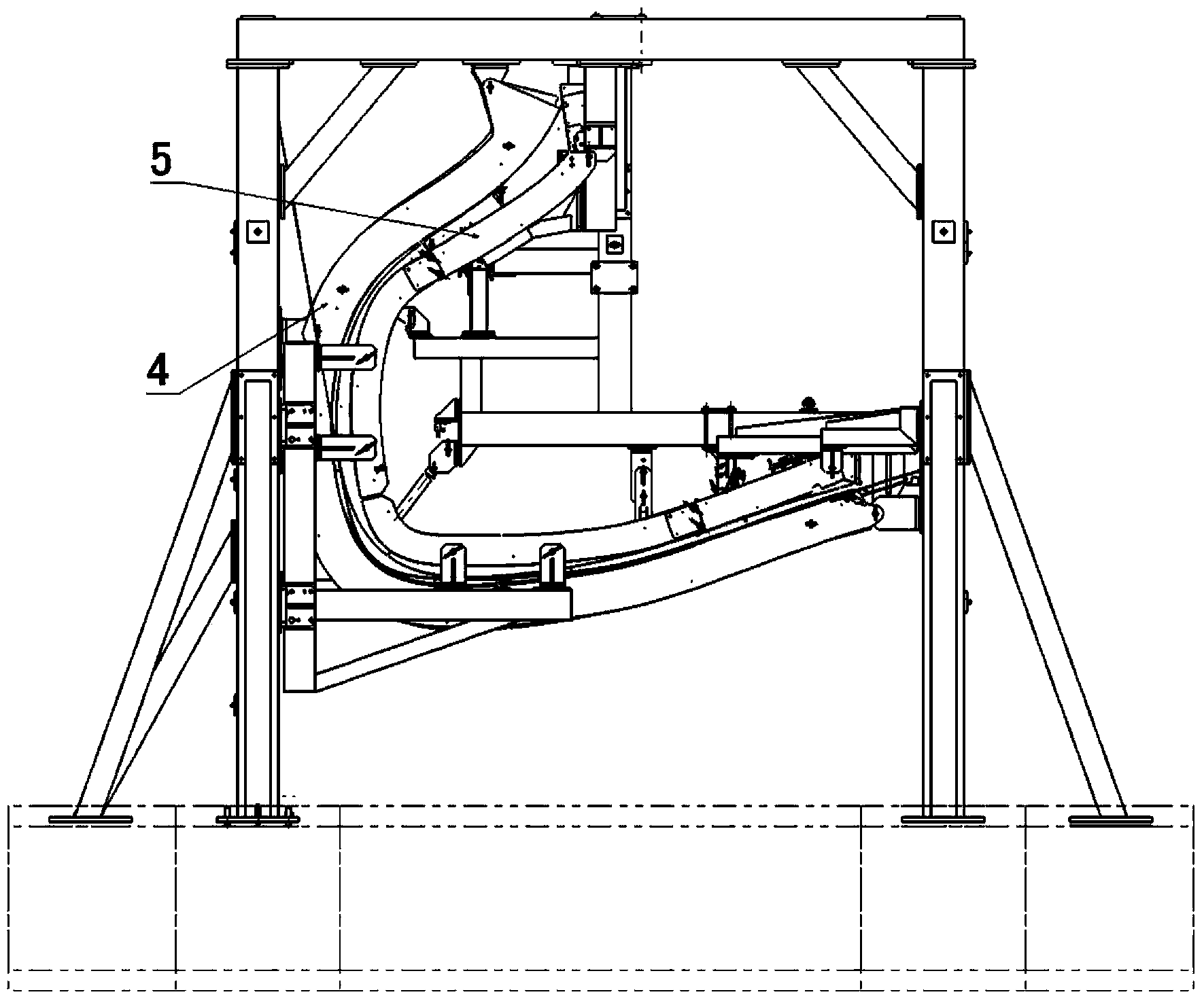

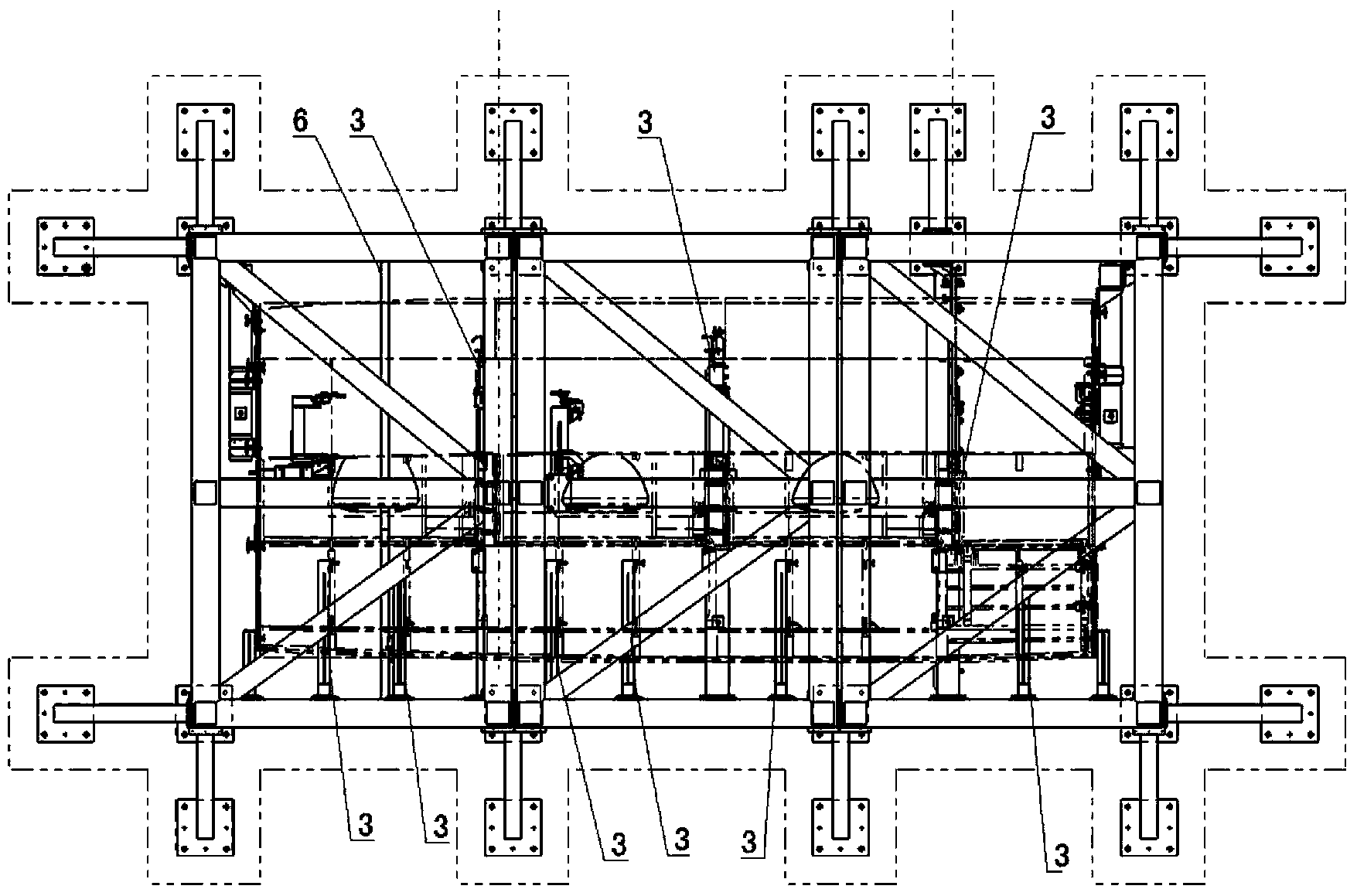

[0013] see figure 1 , figure 2 , image 3 , an aircraft main landing gear door assembly coordination platform, comprising a foundation 1, a main frame 2, a door intersection positioning assembly 3, a door shape detection clamp 4, a main landing gear fairing dummy frame 5 and a tension belt assembly 6. The main frame 2 is installed on the foundation 1; the hatch door intersection positioning assembly 3, the hatch shape detection clamp 4, and the tension belt assembly 6 are installed on the main frame 2; the hatch door intersection positioning assembly 3 The positioning coordinates are consistent with the coordinates of the intersection point of the actual cabin door assembly of the aircraft; the inner shape of the hatch shape detection clamp 4 is consistent with the theoretical shape of the hatch, and the inner shape of the hatch shape det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com