A quick release valve built-in diaphragm and quick release valve

A diaphragm and body technology, which is applied in the field of quick release valve built-in diaphragm and quick release valve, can solve the problems of taking up a lot of space, high cost, and unable to reduce howling, so as to reduce the generation of high frequency vibration and reduce the concentration of force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

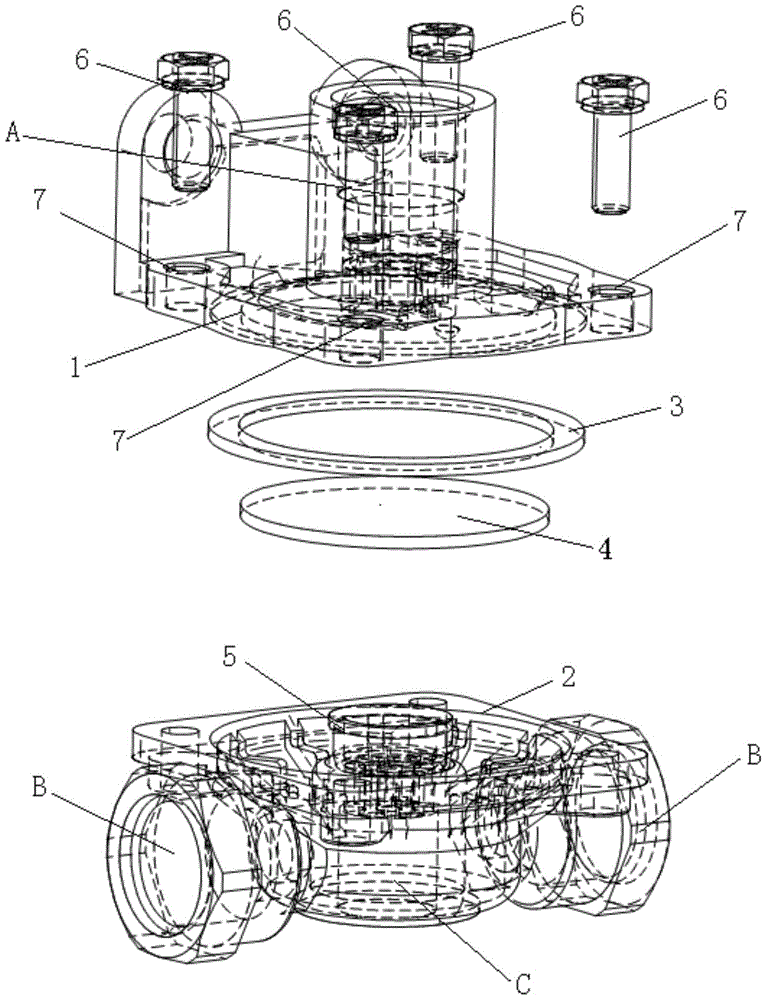

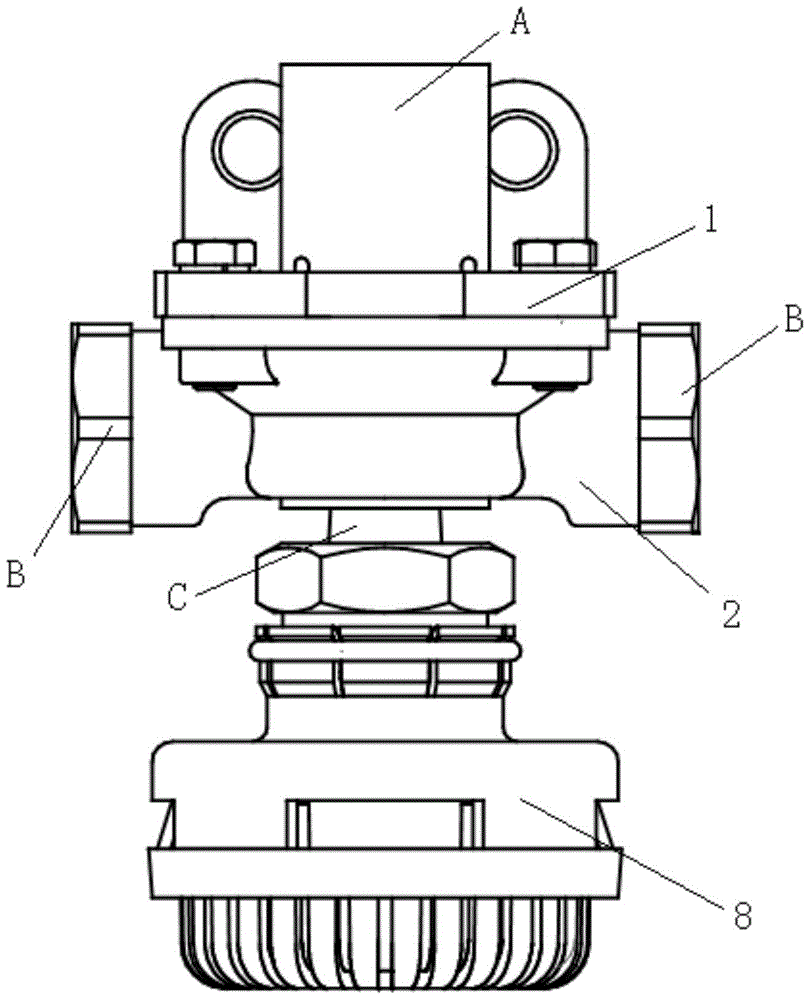

[0041] Such as Figure 4 to Figure 7 As shown, a quick-release valve includes a built-in diaphragm of the quick-release valve, an upper casing, a lower casing, an air release valve, a sealing ring and fastening bolts; the quick-release valve of the present application is only for the existing The diaphragm of the quick-release valve is structurally improved, and the damping equipment is omitted, and other structures of the quick-release valve are the same as the prior art.

[0042] An air inlet is provided on the upper casing, and four screw holes are arranged on the upper casing for passing fastening bolts; the air inlet is connected with an air source.

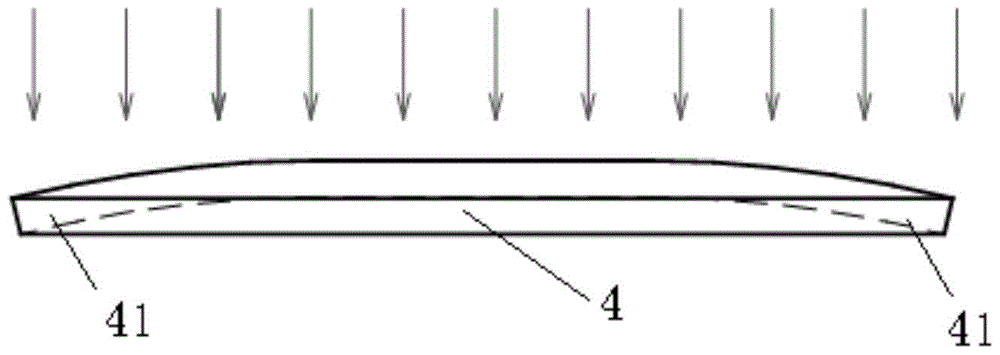

[0043] The built-in diaphragm of the quick-release valve includes a diaphragm body 101, and a first boss structure 111 is arranged on the upper surface of the diaphragm body 101; The centers coincide.

[0044] On the upper surface of the diaphragm body 101, from the circumscribed circle of the first boss structure 111 to t...

Embodiment 2

[0054]In other embodiments of the present application, other parts of the quick release valve body are the same as in embodiment 1, and only the structure of the built-in diaphragm of the quick release valve is improved. Therefore, in the following embodiments, only the quick release valve is described Structure of built-in touch pads.

[0055] The built-in diaphragm of the quick-release valve is made of rubber or polymer material or polyester material, and includes a diaphragm body, and a first boss structure is arranged on the upper surface of the diaphragm body; the first boss structure The center coincides with the center of the diaphragm body;

[0056] The diameter of the circumscribed circle of the first boss structure is smaller than the diameter of the air inlet, which can ensure that the high-pressure gas enters the quick release valve. In this embodiment, the section of the first boss structure parallel to the plane of the diaphragm body is circular. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com