Upper shell of quick release valve for braking, as well as quick release valve

A shell and body technology, which is applied in the field of the upper shell and quick release valve of the brake quick release valve, can solve the problems of not being able to reduce the howling, small force bearing area of the diaphragm, and taking up a lot of space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

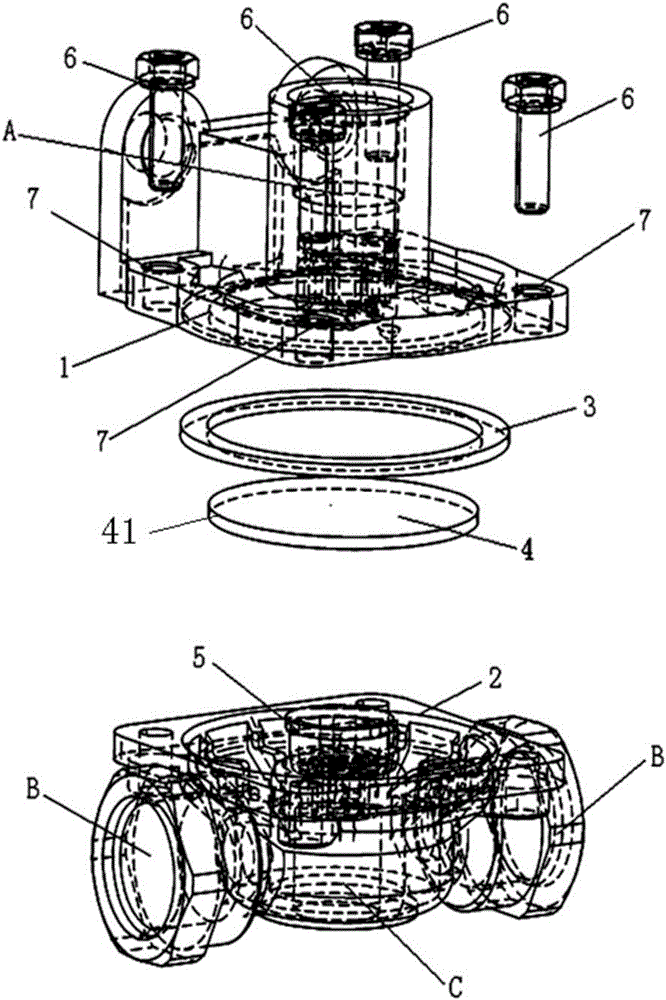

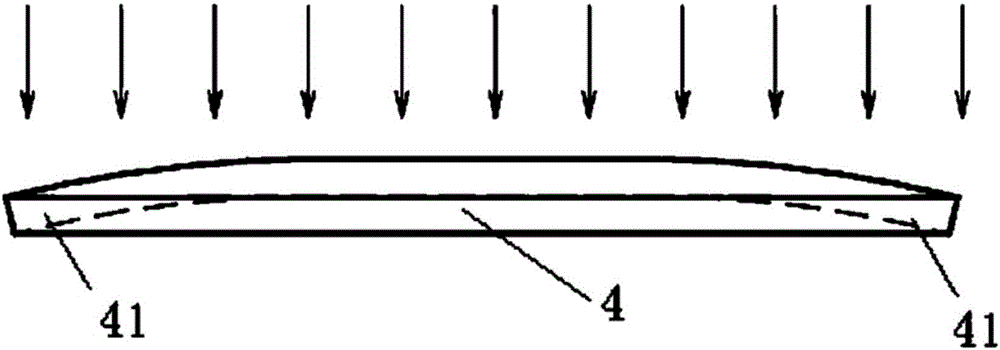

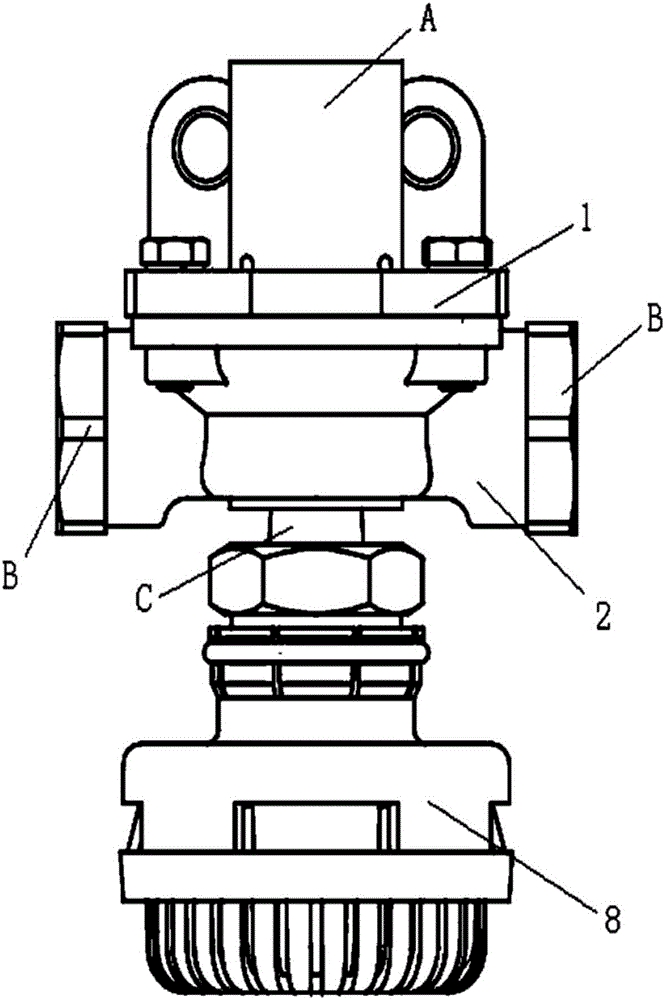

[0032] This application provides an upper housing of a quick release valve for braking, such as Figure 5 and Figure 6 As shown, the upper housing body 100 is included, and an air inlet chamber 200 is arranged above the upper housing body 100. The air inlet chamber 200 communicates with the inner cavity of the upper housing body 100, and the gas enters the upper housing body through the air inlet chamber. , and apply pressure to the diaphragm 300 .

[0033] The air inlet chamber 200 includes a cylindrical cavity 201 and a conical cavity 202 positioned below the cylindrical cavity; the end with a small diameter in the conical cavity i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com