A built-in diaphragm of a quick release valve for air pressure brake and a quick release valve

A pneumatic brake and diaphragm technology, applied in the direction of brakes, brake components, control valves and air release valves, etc., can solve the problems of large space occupation, high cost, and inability to reduce howling, so as to reduce high-frequency vibration , reducing the effect of force concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

[0041] The upper surface described below in this application means that the surface facing the upper casing is the upper surface, and the surface facing the lower casing is the lower surface.

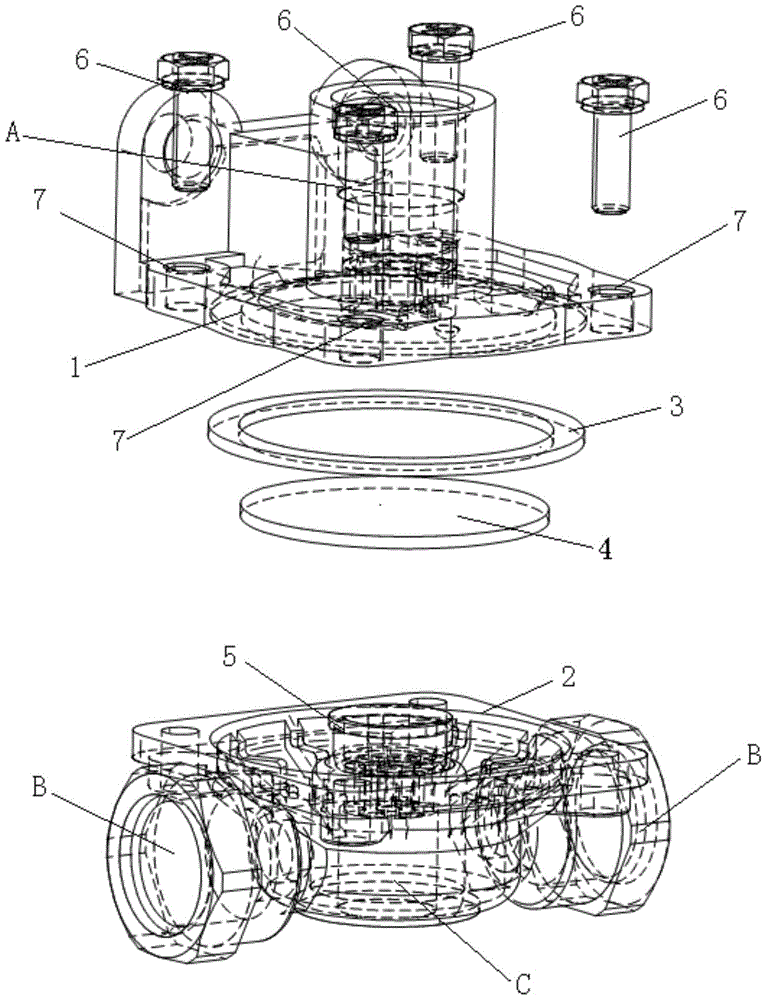

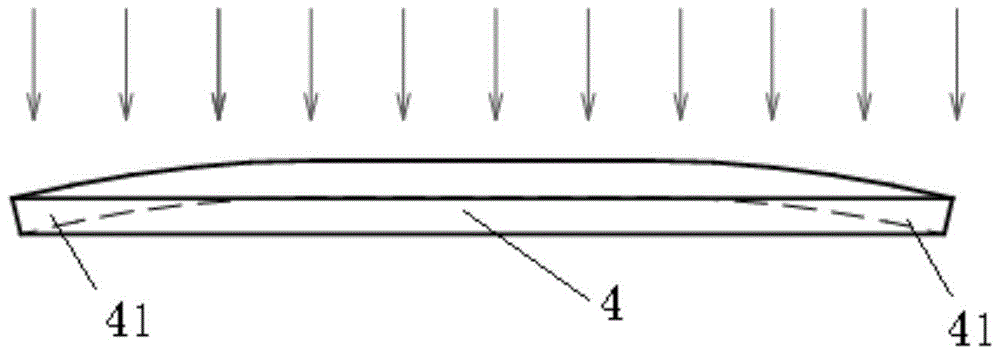

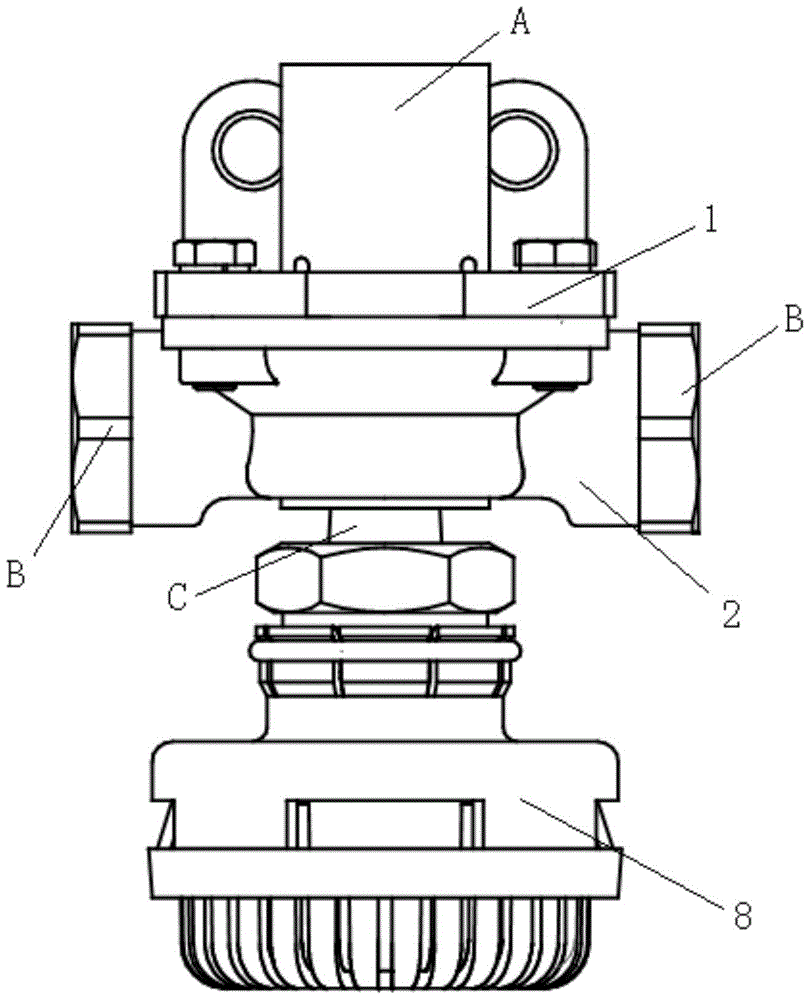

[0042] A quick-release valve for air pressure braking, including a built-in diaphragm of the quick-release valve, an upper casing, a lower casing, an air-release valve, a sealing ring and fastening bolts; the quick-release valve of the present application is only for the existing The diaphragm of the quick-release valve is structurally improved, and the damping equipment is omitted, and other structures of the quick-release valve are the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com