Method for controlling roll gap of pinch roll

A control method and technology of pinch rollers, which are applied in manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problem that the belt threading head cannot be pinch normally, the gap between the pinch rollers is irregular, and the surface characteristics are very different. It can reduce the damage of the lead strip, strengthen the automatic adaptation, and improve the antegrade rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings.

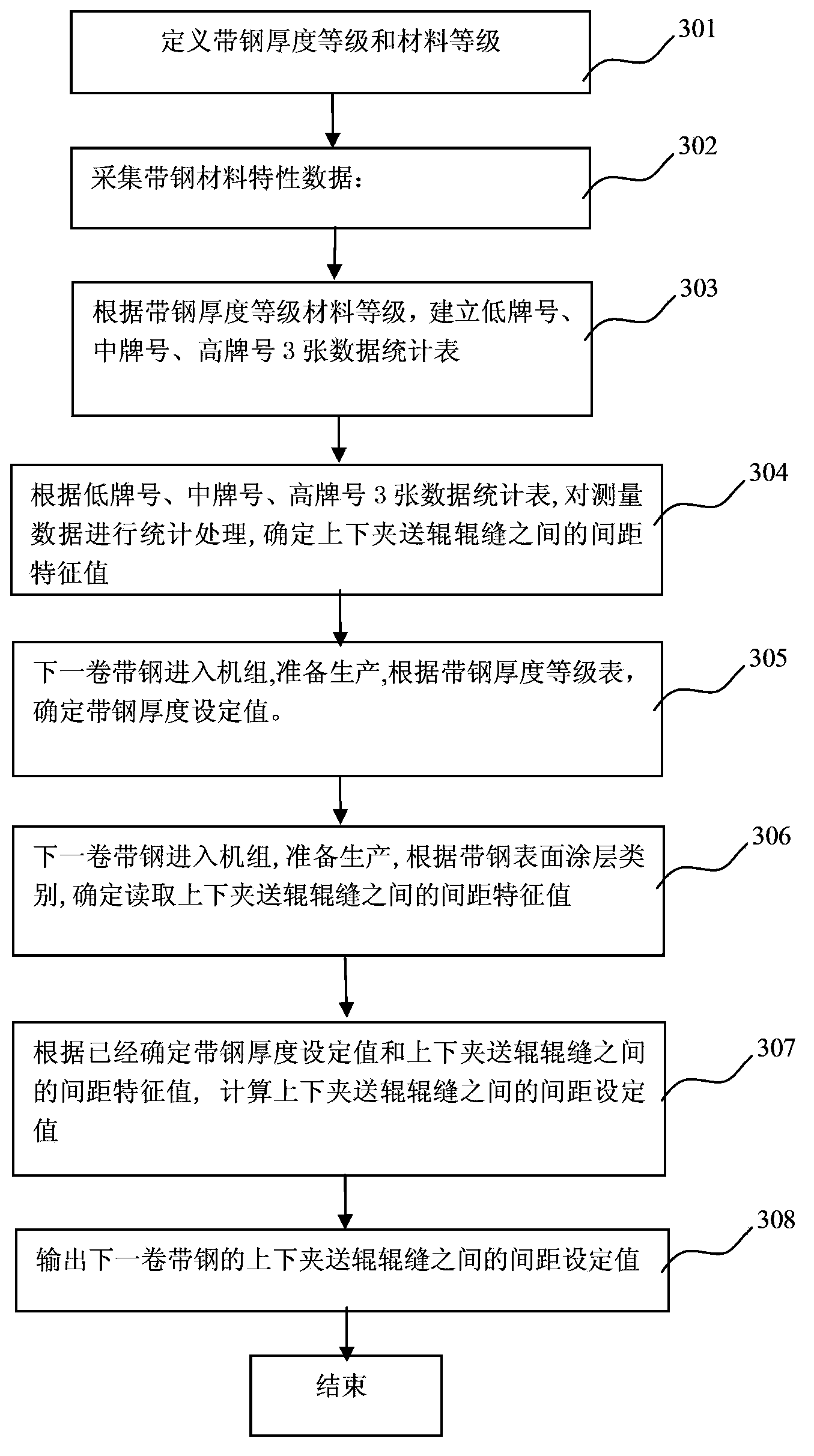

[0048] image 3 It is a flow chart of the pinch roll gap control method of the present invention.

[0049] As shown in the figure, step 301 is to divide the steel strip thickness grade and the silicon content grade of the material; the strip steel produced is divided into 5 strip steel thickness grades according to the thickness, and the strip steel is divided into low grade, high grade, high grade steel strip according to the silicon content of the material. There are three grades of silicon content in materials of medium grade and high grade. As shown in Table 2 and Table 3, the strip thickness grade table and material silicon content grade table.

[0050]Table 2: Strip Thickness Grade Table

[0051] Strip Thickness (mm)

Strip Thickness Grade

Strip thickness setting value T(mm)

0.10≤H<0.18

1

0.15-0.19

0.18≤H<0.30

2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com