Elbow forming machine

A technology of forming machine and pipe bending, applied in the field of pipe processing, can solve the problems of high labor cost, low production efficiency, complicated process, etc., and achieve the effect of convenient processing technology and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

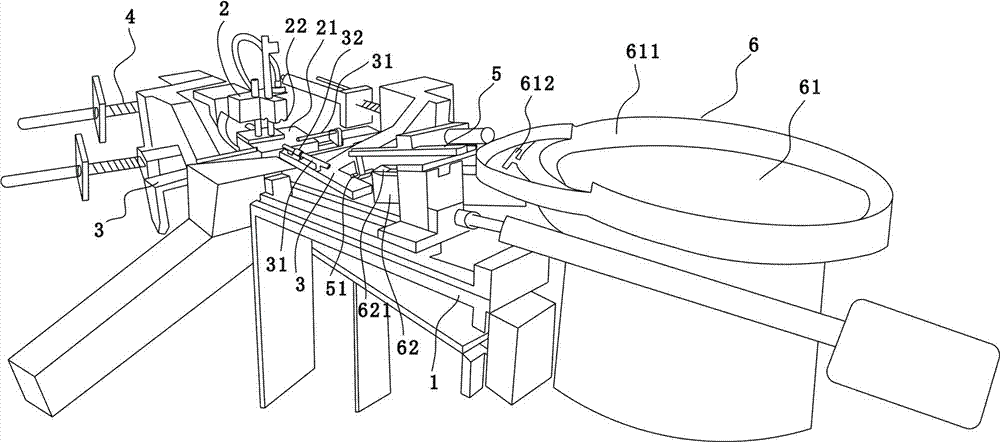

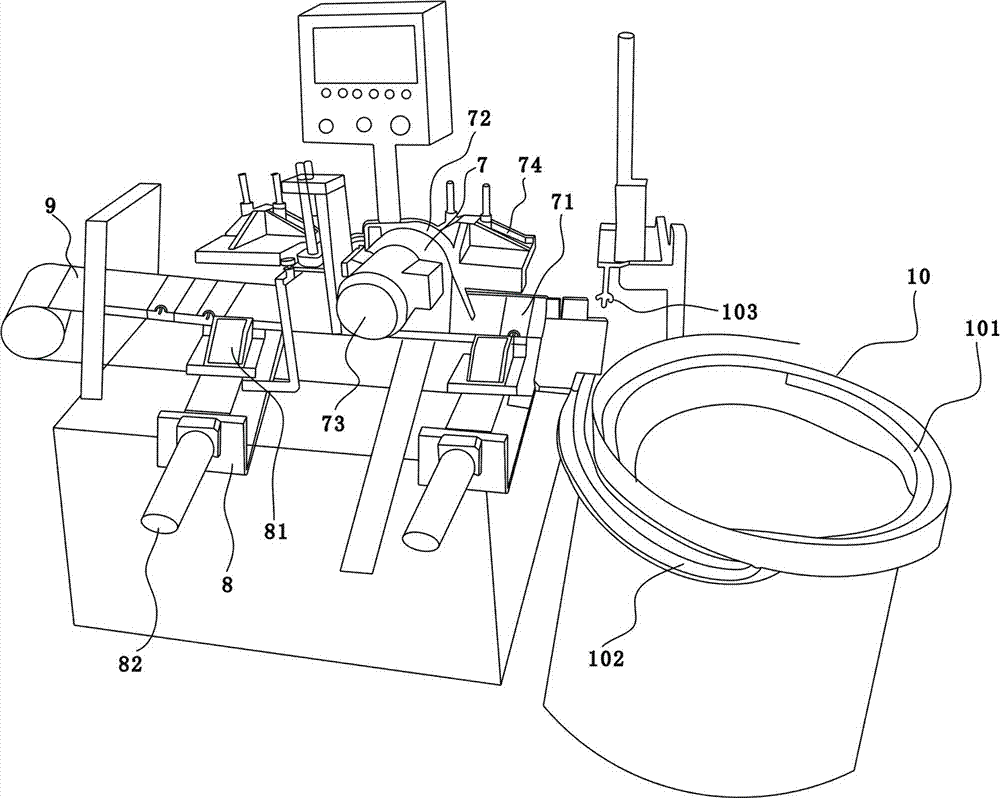

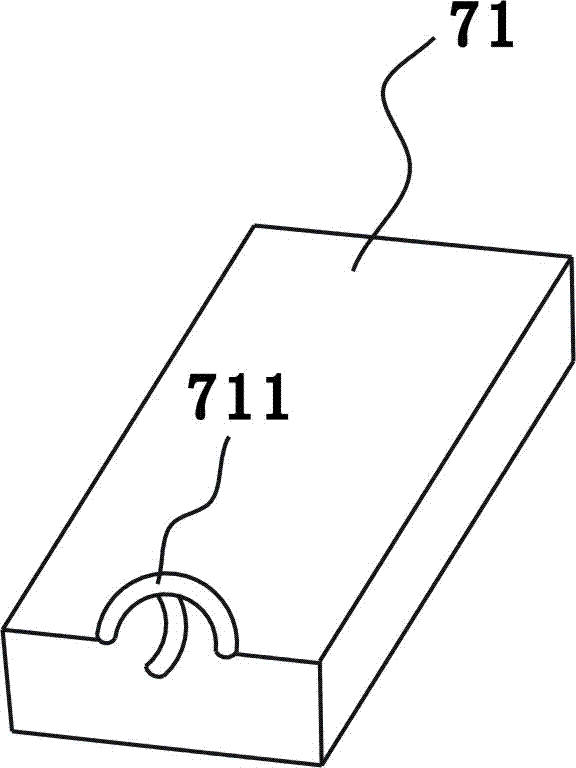

[0022] figure 1 Shown is a schematic structural diagram of a pipe bending machine provided by an embodiment of the present invention. figure 2 Shown is a schematic structural view of a leveling device and a flaring device in a pipe bending machine provided by an embodiment of the present invention. image 3 Shown as figure 2 The illustrated schematic diagram of the enlarged structure of the second fixing member in the pipe bending machine.

[0023] This embodiment provides a bending pipe forming machine, which includes a carrying table 1, a first fixing part 2, a forming part 3, and a first driving part 4. The first fixing member 2 is fixed to the carrying platform 1 and includes a first working table 21 and a second working table 22 which is arranged above the first working table 21 and can move up and down. The work piece is placed on the first workbench 21, and the second workbench 22 is provided with a fixing groove for fixing the work piece branch pipe. The number of mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com