An automatic pipe bending device for the outer exhaust pipe of a compressor

A technology for an external exhaust pipe and a pipe bend device is applied in the field of compressor manufacturing, which can solve the problems of large workload, large physical strength, and inability to guarantee the process, and achieves the effects of improving processing efficiency, high production efficiency, and reducing labor force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

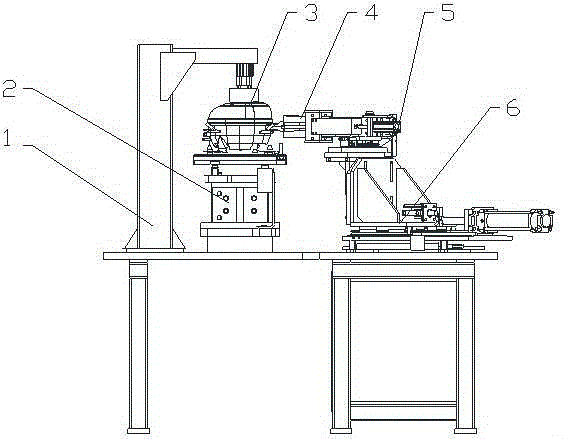

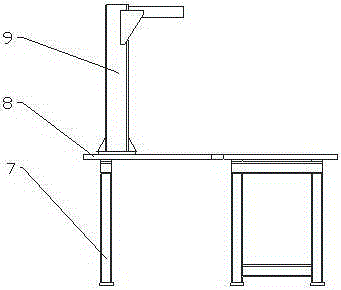

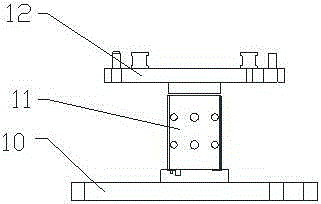

[0023] The accompanying drawings disclose non-restrictive structural schematic diagrams of preferred embodiments involved in the present invention; the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0024] An automatic pipe bending device for an outer exhaust pipe of a compressor, the automatic pipe bending device for an outer exhaust pipe of a compressor includes a frame component 1, a jacking mechanism 2, a pressing mechanism 3, a pipe bending claw mechanism 4, a rotating bend The pipe mechanism 5 and the transfer mechanism 6, the jacking mechanism 2, the pressing mechanism 3 and the transfer mechanism 6 are installed on the frame part 1, the rotating bending mechanism 5 is installed on the transferring mechanism 6, and the bending jaws Mechanism 4 is installed on the rotary pipe bending mechanism 5 .

[0025] The frame part 1 is composed of a chassis 7 , a mounting plate 8 , and a mounting brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com