Air knife device of glass air knife cleaning machine

A cleaning machine and air knife technology, applied in dryers, drying gas arrangement, cleaning methods and utensils, etc., can solve the problems of inconsistent drying degree on the upper and lower surfaces of glass, inability to adjust the air knife distance quickly and easily, affecting packaging operations, etc. To achieve the effect of easy adjustment, smooth conveying, and easy adjustment and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

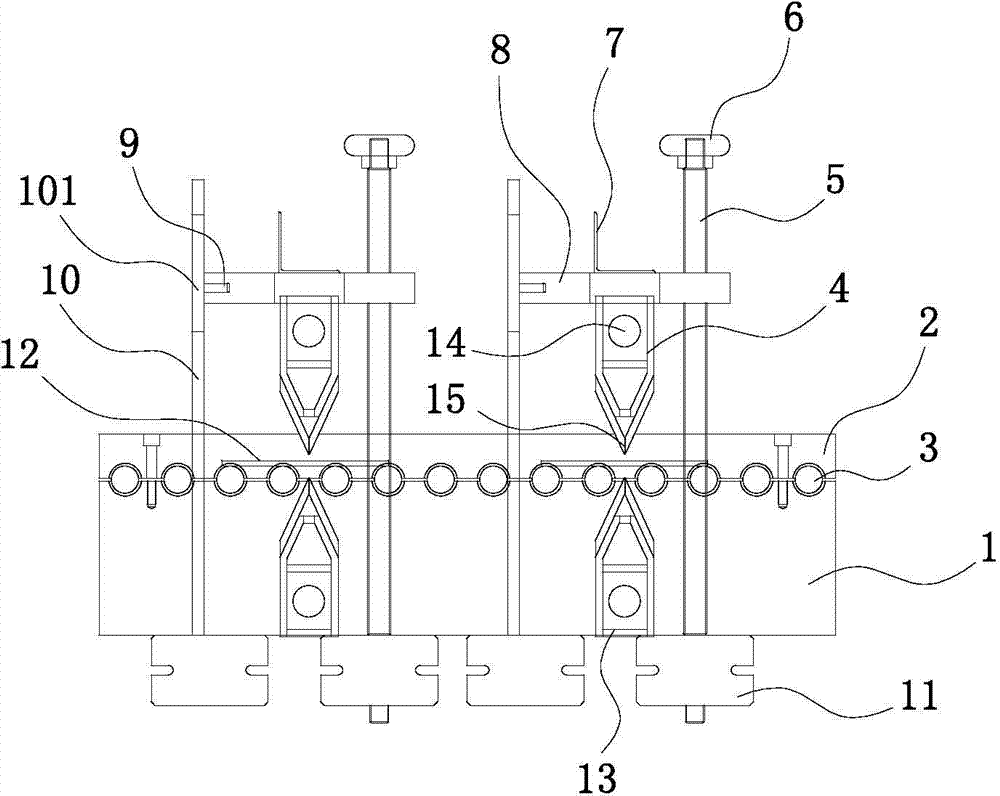

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, the air knife device of the glass air knife cleaning machine of the present embodiment includes symmetrically arranged bases, and a conveyor belt and an air knife are installed between the two bases. The conveyor belt is composed of a plurality of parallel guide rollers 3, and the guide The ends of the roller 3 are respectively provided with pulleys; the base is composed of an upper seat 1 and a lower seat 2, and the air knife includes an upper air knife 4 and a lower air knife 13;

[0014] The lower surface of the upper seat 1 and the upper surface of the lower seat 2 are respectively provided with corresponding semicircular grooves, and the guide roller 3 is rotated and connected in the clamping hole formed by the upper and lower semicircular grooves;

[0015] The base is connected to the bracket by means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com