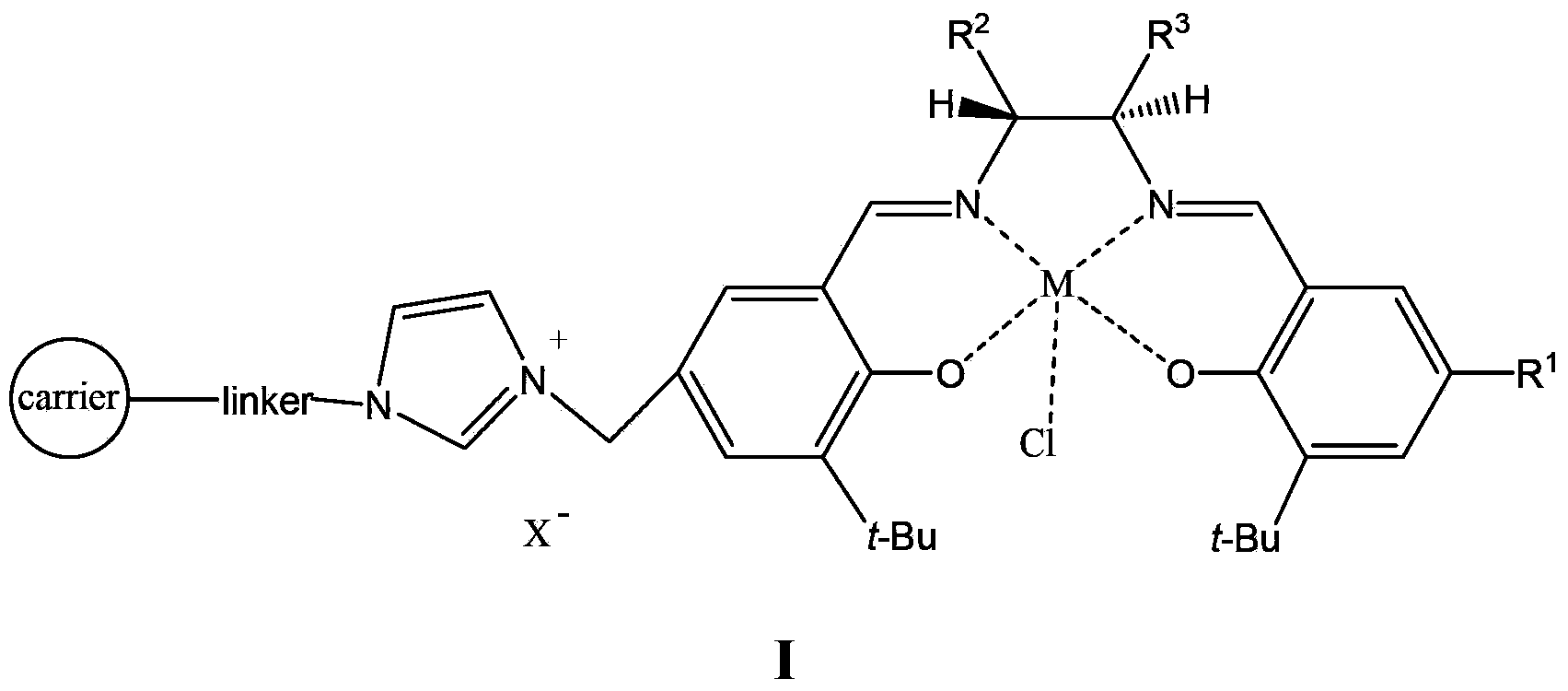

Supported catalyst and preparation method thereof

A technology of supported catalysts and compounds, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc. Rate and enantioselectivity decline and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

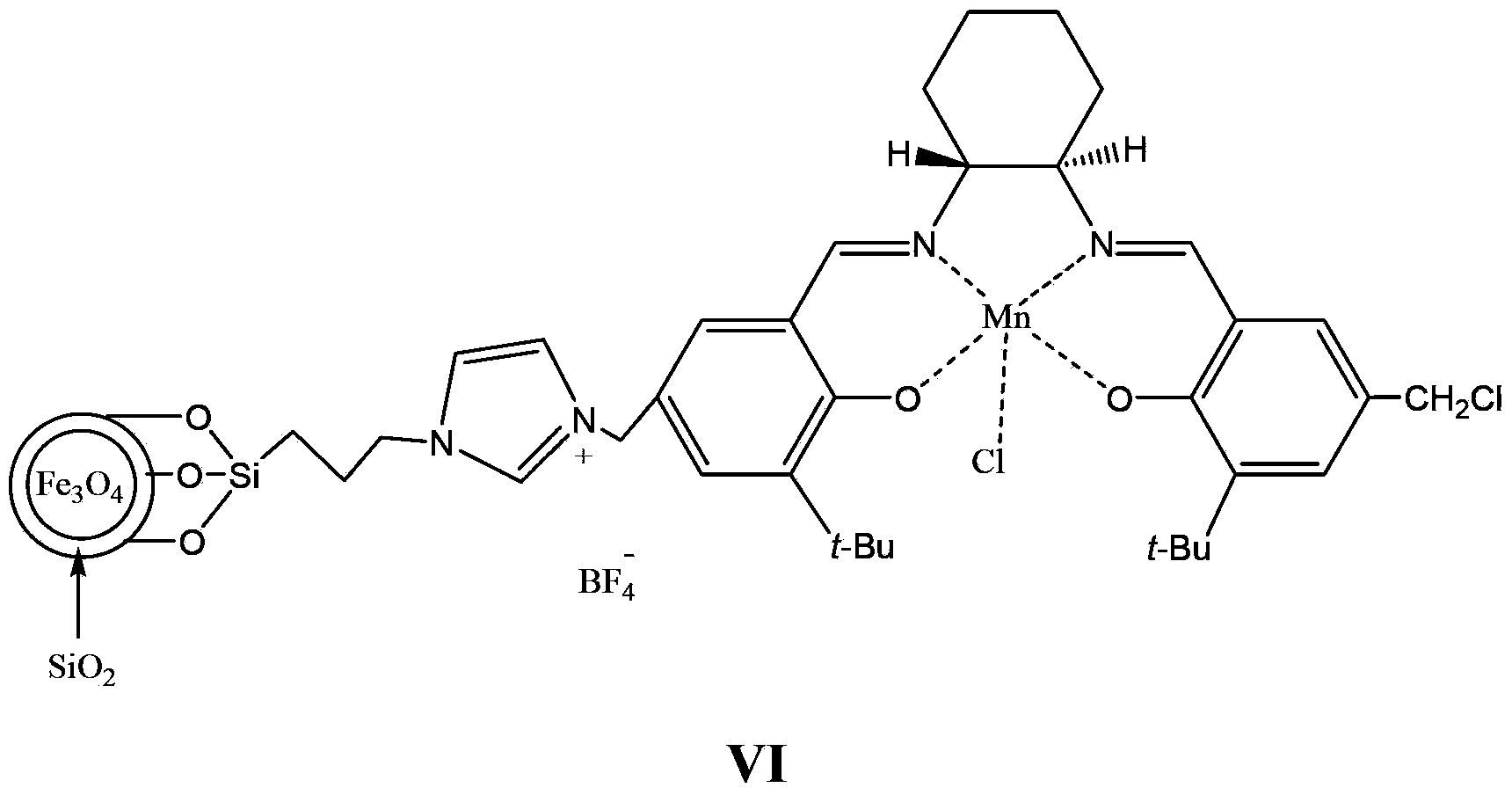

Embodiment 1

[0080]

[0081] The experimental device is mainly a three-neck flask. In order to stir fully, mechanical stirring is used, and the system is protected with nitrogen. Place the accurately weighed compound of formula 5 (14.8g, 10mmol, 0.68mmol / g as imidazole), the compound of formula 1 (12mmol) and 80mL of toluene in a flask, place the flask in an oil bath, stir at a high speed, and reflux the reaction After 24 hours, add an external magnetic field, pour the liquid, and then add 15 mmol of Mn(OAc) 2 4H 2 O, 60mL absolute ethanol, after reflux for 1 hour, add lithium chloride (15mmol) to continue the reflux reaction for 1 hour, add a magnetic field, pour the liquid, add 100mL methanol, NaBF 4 (15 mmol) after reflux reaction for 10 hours, a magnetic field was added, the liquid was poured, and the obtained solid liquid was washed 3 times with anhydrous ether, and dried in vacuum at 60° C. for 5 hours to obtain 14.1 g of a light yellow solid. After elemental analysis, the loadi...

Embodiment 2

[0083]

[0084] The experimental device is mainly a three-neck flask. In order to stir fully, mechanical stirring is used, and the system is protected with nitrogen. Place the accurately weighed compound of formula 5 (14.8g, 10mmol, 0.68mmol / g in terms of imidazole), the compound of formula 2 (15mmol) and 80mL of toluene in a flask, place the flask in an oil bath, stir at a high speed, and reflux the reaction After 24 hours, add an external magnetic field, pour the liquid, and then add 15 mmol of Mn(OAc) 2 4H 2 O, 80mL of absolute ethanol, add lithium chloride (15mmol) after reflux for 1 hour and continue to reflux for 1 hour, add a magnetic field, pour the liquid, add 100mL of methanol, LiNTf 2 (15 mmol) after reflux reaction for 24 hours, a magnetic field was added, the liquid was poured, and the obtained solid liquid was washed three times with anhydrous ether, and dried in vacuum at 60° C. for 5 hours to obtain 14.6 g of a light yellow solid. After elemental analysis,...

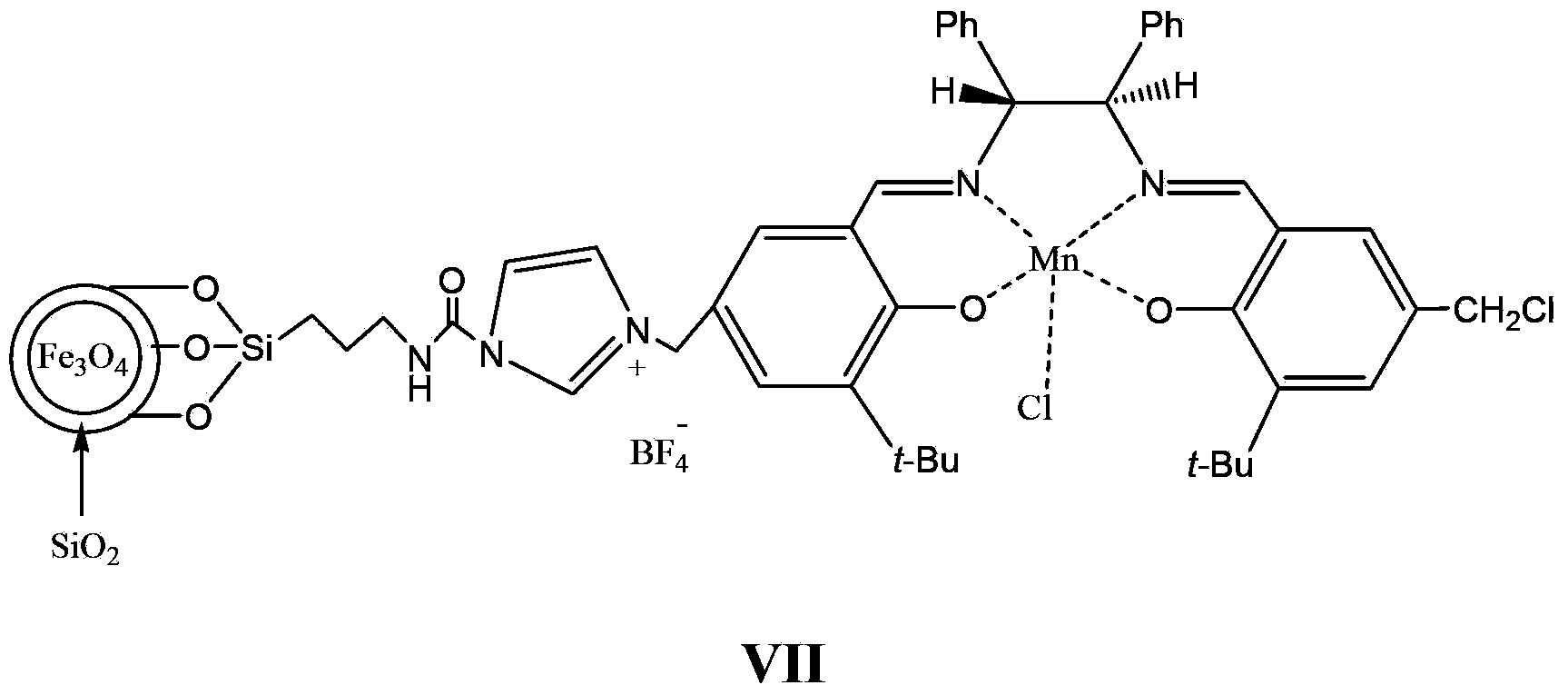

Embodiment 3

[0086]

[0087] The experimental device is mainly a three-neck flask. In order to stir fully, mechanical stirring is used, and the system is protected with nitrogen. Place accurately weighed compound of formula 6 (15.6g, 10mmol, 0.64mmol / g in terms of imidazole), compound of formula 3 (13mmol) and 80mL of toluene in a flask, place the flask in an oil bath, stir at a high speed, and reflux the reaction After 24 hours, add an external magnetic field, pour the liquid, and then add 15 mmol of Mn(OAc) 2 4H 2 O, 80mL absolute ethanol, after reflux for 1 hour, add lithium chloride (15mmol) to continue the reflux reaction for 1 hour, add a magnetic field, pour the liquid, add 110mL methanol, KPF 6(15 mmol) after reflux reaction for 12 hours, a magnetic field was added, the liquid was poured, and the obtained solid liquid was washed 3 times with anhydrous ether, and dried in vacuum at 60° C. for 5 hours to obtain 13.9 g of a light yellow solid. According to elemental analysis, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com