Yarn draw-off unit of a rotor spinning machine and method for producing a yarn with the aid of a rotor spinning machine

A technology of rotor spinning machine and yarn, which is applied in the direction of spinning machine, open-end spinning machine, continuous winding spinning machine, etc., and can solve the problems of false twist strength limit and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

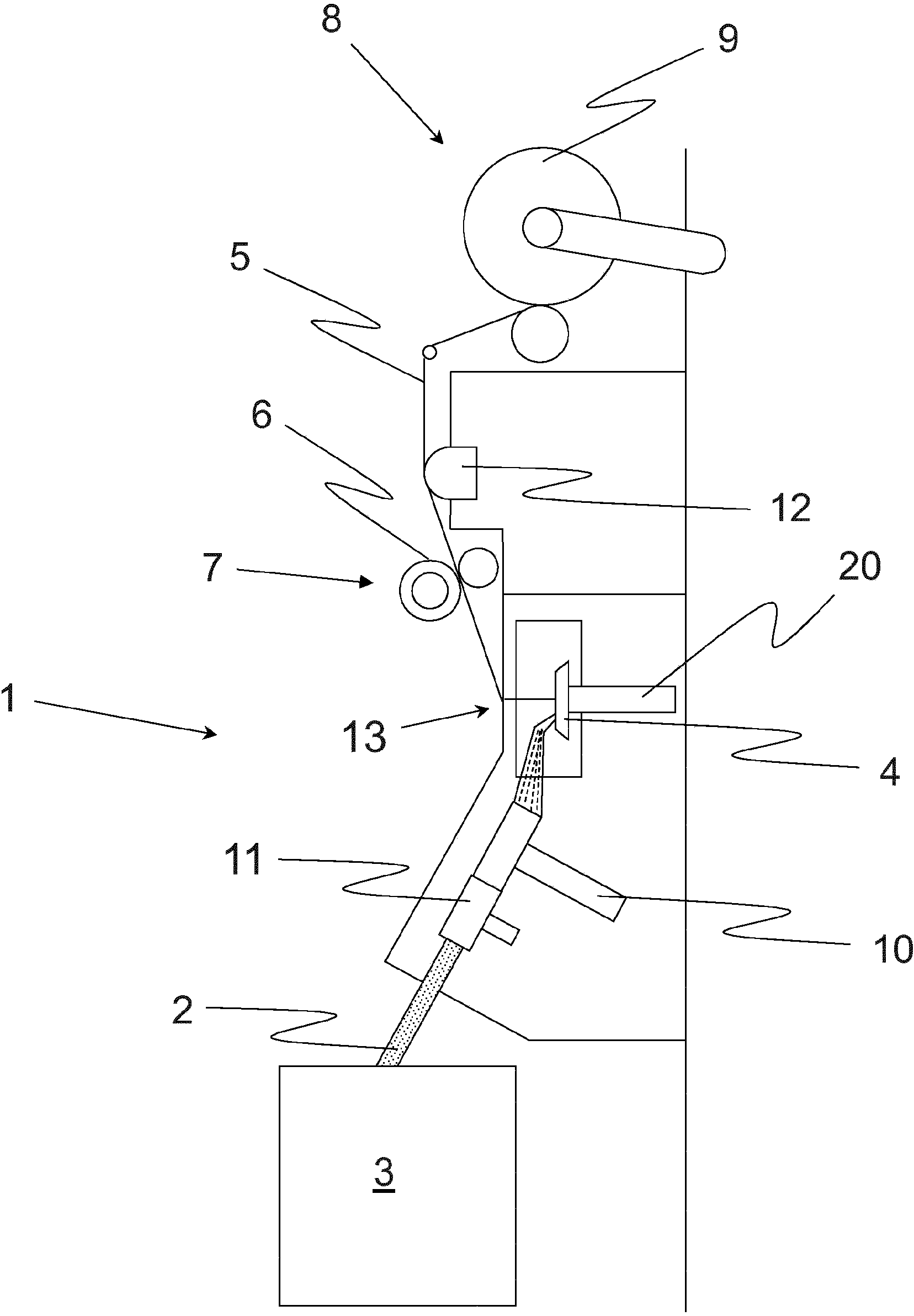

[0035] figure 1 Shown is a partial sectional side view of a known rotor spinning machine, which typically comprises a plurality of spinning positions 1 mounted side by side in the longitudinal direction of the machine, ie in the vertical aspect of the plane. In a known manner, the fiber material 2 coming out of the spinning drum 3 will be conveyed to the individual spinning positions 1 by means of a supply device 11, and by means of an opening roller 10, said fiber material 2 will be carded into individual strands. fiber, then, through figure 2 The fiber supply duct 16 (appearing behind the plane of the paper) marked with dashed lines, the fiber material 2 is to be fed to the spinning rotor 4 . The yarn 5 produced on said spinning rotor 4 is drawn from the spinning position 1 via the outlet 13 by the yarn delivery device 7 contained in the yarn delivery roller pair 6 and checked, if possible, with a yarn monitoring unit 12 The yarn defect is then wound up by the take-up dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com