Method and system for separating cast parts from bunches obtained using casting processes

A technology of casting parts and separation systems, which is applied in the field of steel industry and can solve problems such as long debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

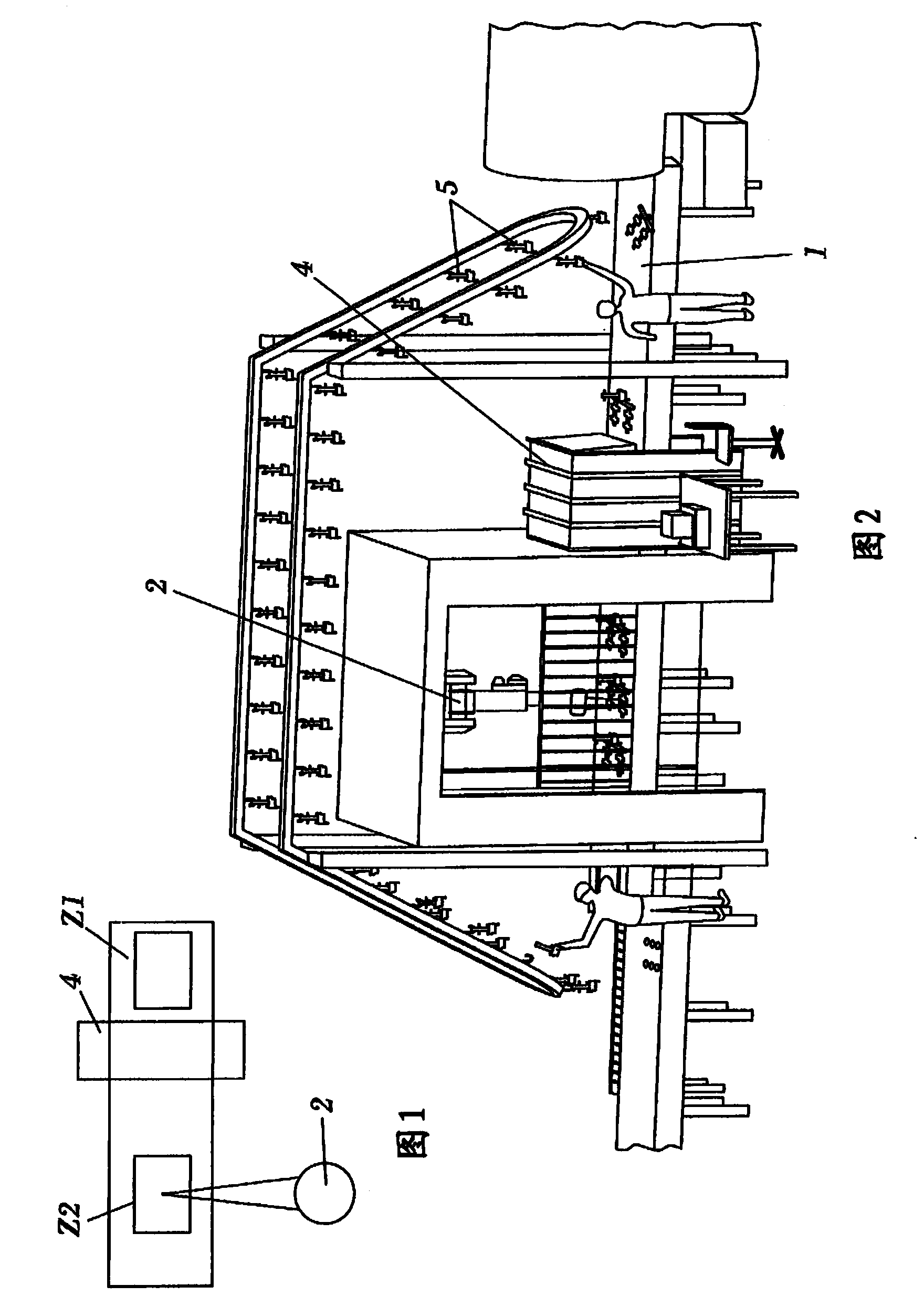

[0169] Figure 1 to Figure 11 A possible separating device for separating parts is shown, in which the invention can be integrated. As can be observed, the group (3) of cast parts to be separated arrives at the separation device either from a previous manufacturing process or by means of the operator.

[0170] The group (3) will pass through the first computer vision system (4) capturing images of the group. Since the first computer vision system (4) is a static vision system, it can be protected from smoke and sand and high temperatures present in the installation by means of a protective cover, and maintain continuous control over the lighting, as well as prevent contact with the outside world. interference. The information obtained by the first computer vision system will be transmitted to a computer device (13) which will manage the data of the first computer vision system (4). The location of significant points relative to predetermined fiducials of the cast part (14) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com