A kind of drift tube with support rod and preparation method thereof

A technology for drift tubes and support rods, applied in the field of drift tubes, can solve problems such as difficult processing, achieve the effects of improving surface finish, increasing acceleration gradient, and reducing the maximum surface electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A drift tube with a support rod, the processing method of which is as follows:

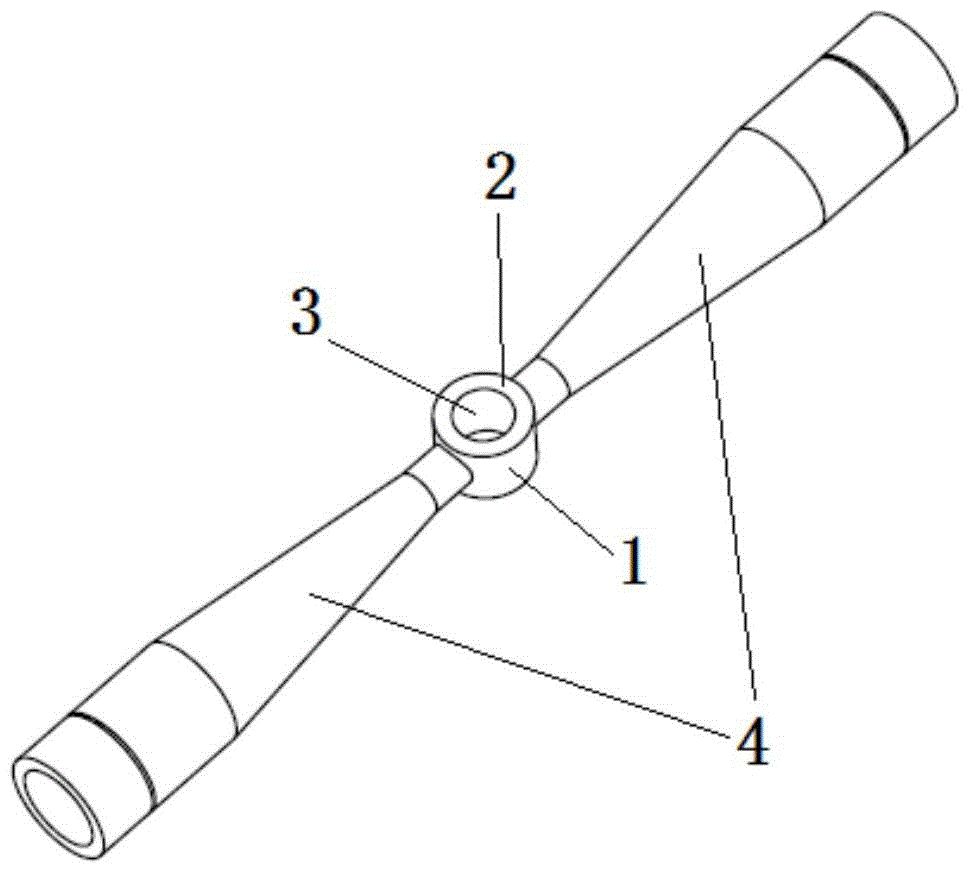

[0035] 1. Use a lathe to turn the blank into a support rod 4 connected with a sphere;

[0036] 2. Process two sections 2 on the sphere;

[0037] 3. Remove a cylinder whose axis is the line connecting the centers of the two cross-sections 2 to form the beam channel 3 and obtain the drift tube 1;

[0038] 4. Process the cooling water flow channel on the drift tube 1, then seal the opening part necessary for processing by welding, and polish the welding part;

[0039] 5. Process the cooling water channel connected to the cooling water channel of the drift tube inside the support rod 4 .

Embodiment 2

[0041] A drift tube with a support rod, the processing method of which is as follows:

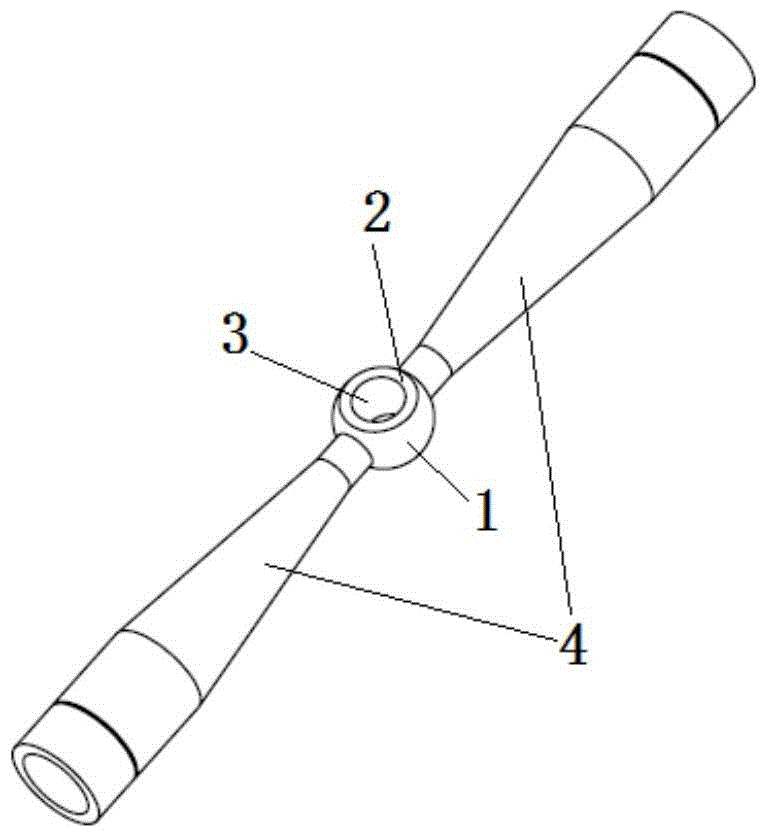

[0042] 1. Use a lathe to turn the blank into a support rod 4 connected with a sphere;

[0043] 2. Process two sections 2 on the spheroid;

[0044] 3. Remove a cylinder whose axis is the line connecting the centers of the two cross-sections 2 to form the beam channel 3 and obtain the drift tube 1;

[0045] 4. Process the cooling water flow channel on the drift tube 1, then seal the opening part necessary for processing by welding, and polish the welding part;

[0046] 5. Process the cooling water flow channel connected with the cooling water flow channel of the drift tube inside the support rod 4 .

[0047] The drift tubes with support rods prepared by the processing methods of Examples 1 and 2 were applied to accelerators. When the accelerator is working, the heat generated by the loss of the radio frequency field on the surface of the drift tube and the support rod is very conveniently ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com