Anti-corrosion device of temperature element of high-pressure cylinder of steam turbine

A technology of temperature element and high-pressure cylinder, which is applied in the field of anti-corrosion device for temperature element of steam turbine high-pressure cylinder, can solve the problems of element measurement failure, steel armor corrosion, and reduced service life of elements, so as to achieve easy installation, maintenance and replacement without affecting measurement accuracy , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

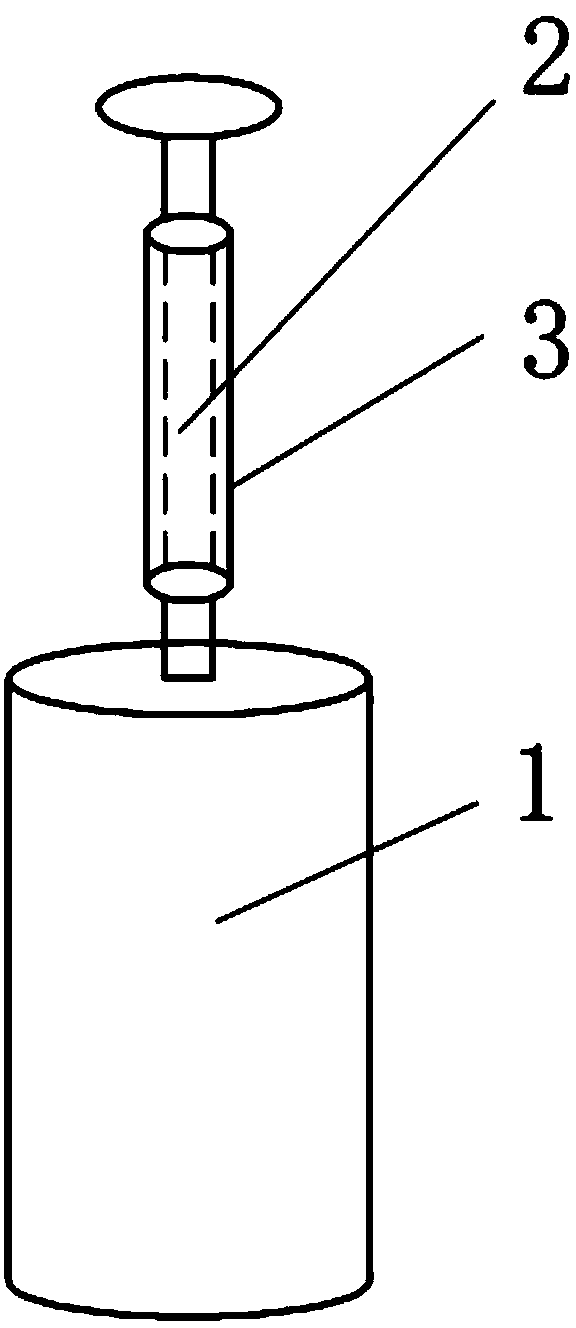

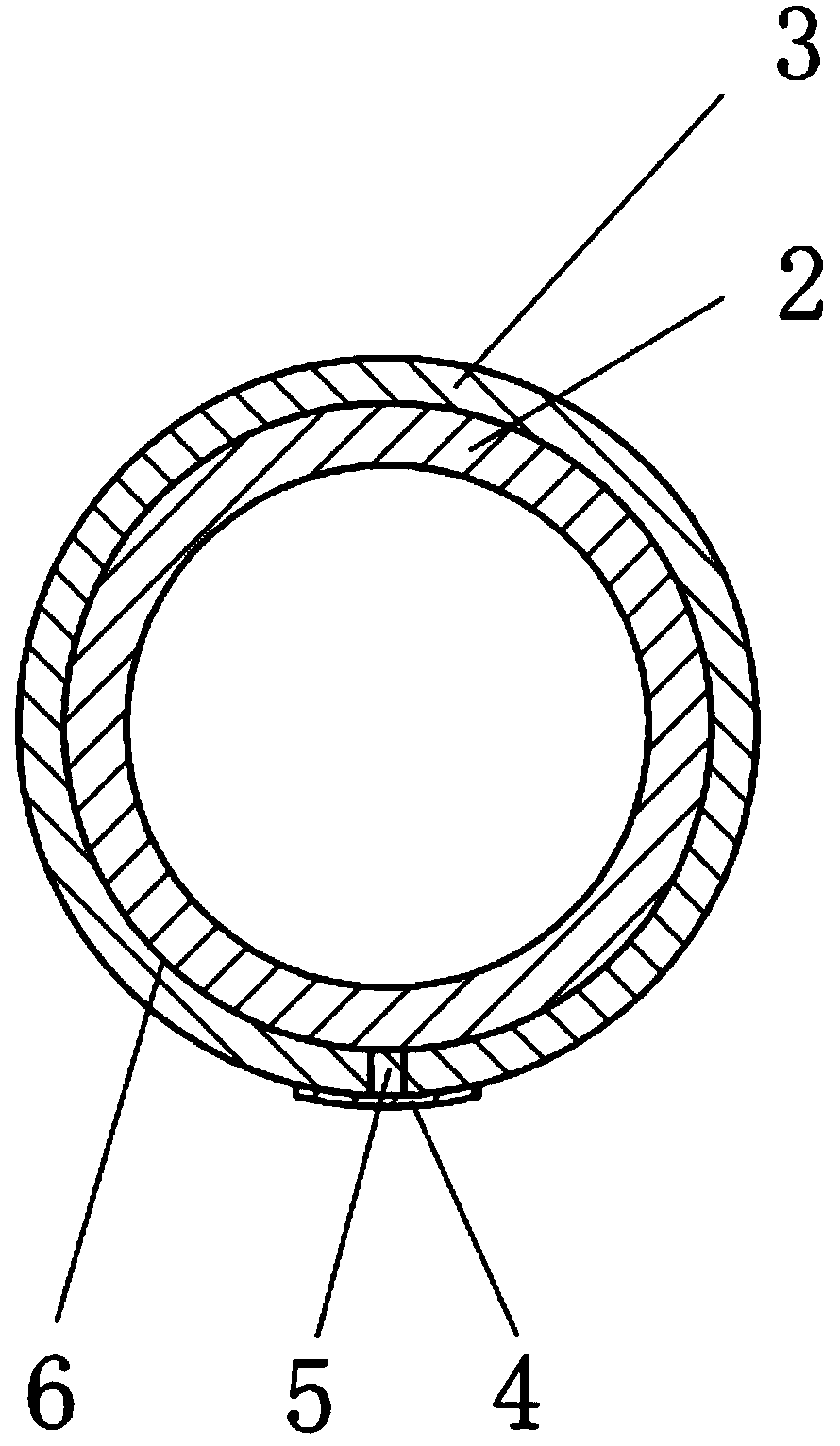

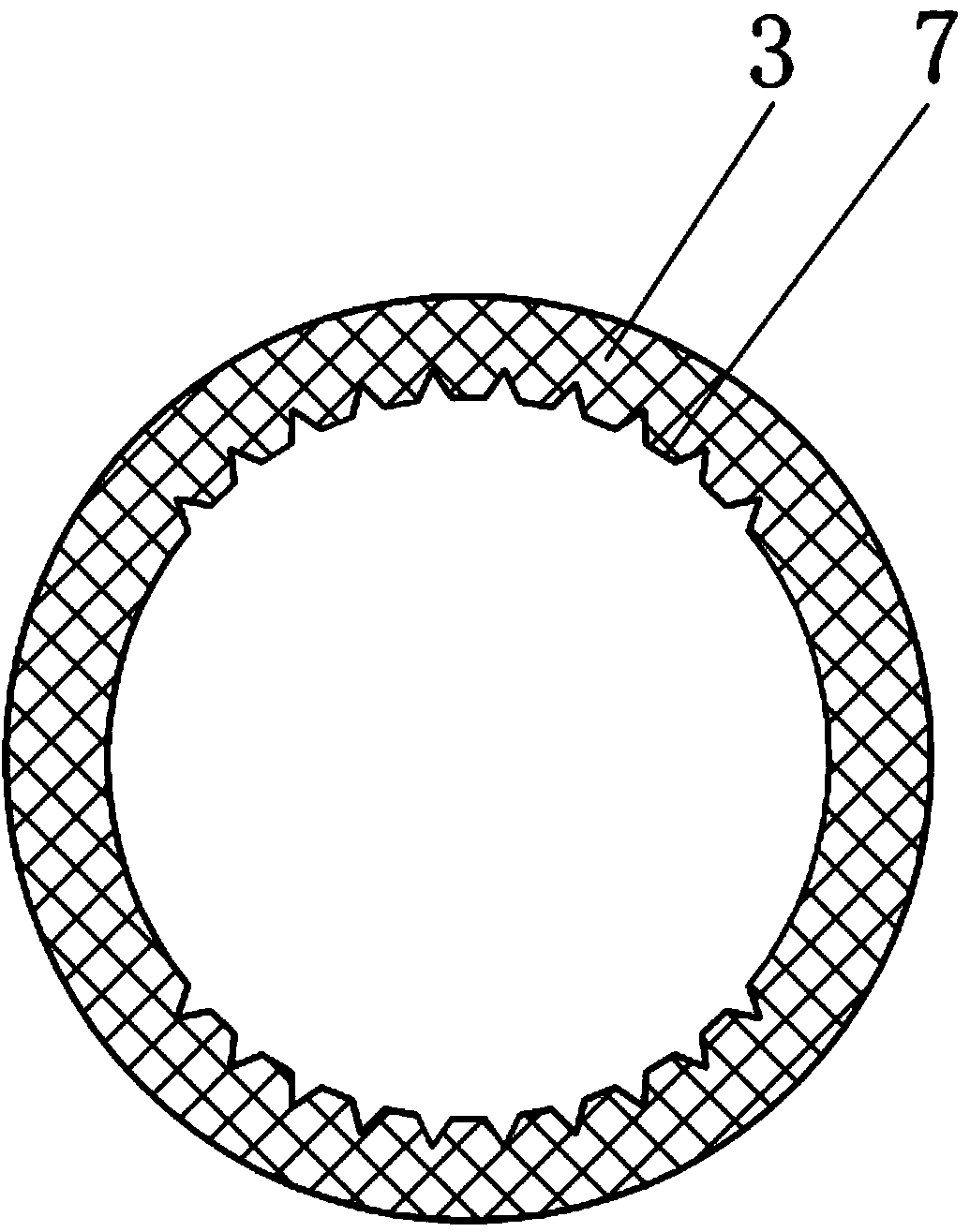

[0014] The specific implementation mode of the present invention is: see figure 1 and figure 2 , including a heat-shrinkable tube and a fixing strip. The heat-shrinkable tube 3 has a long opening 5 in the axial direction. The heat-shrinkable tube 3 is usually made of polymer materials through radiation cross-linking and expansion processes, and has Shape memory, long life and insulation, anti-corrosion effect, split the heat shrinkable tube 3 along the long opening 5, put it on the armored thermocouple 2 on the high pressure cylinder 1 and adjust its position, the heat shrinkable tube 3 is in the opening 5 There may be a seam in the overlapping state, and there may be hot melt glue on the fixing strip 4, and the fixing strip 4 cooperates with the long opening 5 of the heat shrinkable tube 3, so that the heat shrinkable tube 3 becomes a closed whole ; refer to figure 2 , Figure 4 , the inner wall of the heat-shrinkable tube 3 is coated with a hot-melt adhesive layer 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com